PPTC (polymeric positive temperature coefficient) thermosensitive resistor with high voltage withstanding grade and preparing method of PPTC (polymeric positive temperature coefficient) thermosensitive resistor

A technology for thermistors and manufacturing methods, applied in the direction of resistors with positive temperature coefficients, manufacturing encapsulation/housing resistors, etc., can solve the problem of increasing the installation size of PPTC thermistors, low voltage resistance, and easy Problems such as creepage occur, to reduce the probability of creepage, improve withstand voltage, and prevent breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Please refer to the accompanying drawings below to further describe the present invention.

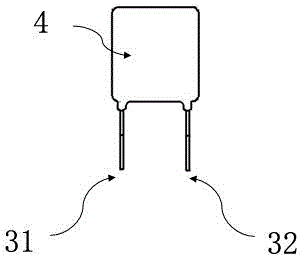

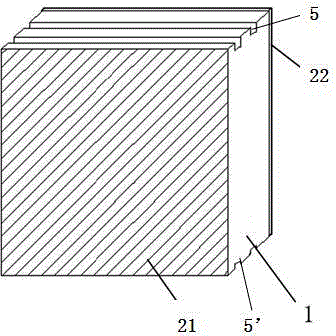

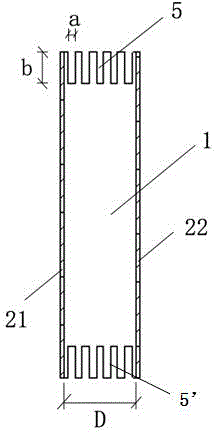

[0048] as attached figure 1 It is a schematic diagram of the appearance of the components of the present invention, attached figure 2 Schematic diagram of the combined structure of PPTC core material and metal foil and attached image 3 As shown in the cross-sectional view of the combination of PPTC core material and metal foil, a PPTC thermistor with high withstand voltage level includes PPTC core material 1, left and right metal foils attached to the PPTC core material 1 The foils 21, 22, the left and right electrodes 31, 32 welded on the outer surface of the metal foil and the insulating layer 4 covering the outside, such as figure 1 As shown, wherein: upper and lower grooves 5, 5' are engraved on the relative upper and lower surfaces of the left and right metal foils on the PPTC core material 1; the thickness of the PPTC core material 1 is 1.0-5.0mm. Such as figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com