A natural gas/diesel dual fuel injector with self-lubricating function

A natural gas and injector technology, which is applied to fuel injection devices, engine lubrication, charging systems, etc., can solve problems such as increased wear and lack of lubrication, and achieve the effect of improving service life, optimizing emission performance, and reducing injection wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

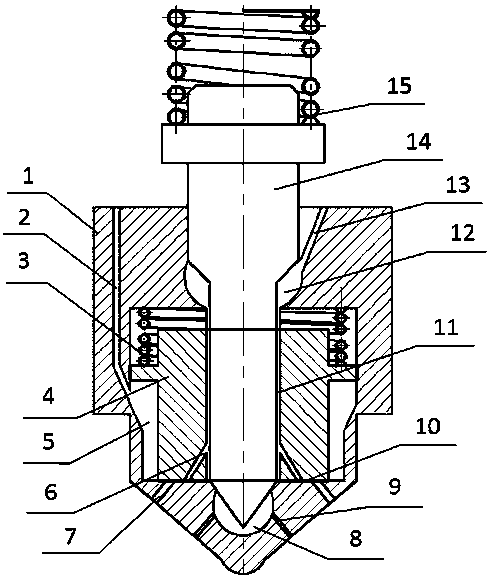

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0039] The working principle of a natural gas / diesel dual fuel injector with self-lubricating function provided by the present invention is to inject a small amount of diesel oil (accounting for about 5%-10% of the total fuel) into the cylinder before the engine piston runs to the top dead center , the trace diesel oil is further compressed to be compression-ignited, and then natural gas is injected into the cylinder at a pressure of 15 MPa, forming a concentration-layered mixture around the trace diesel flame, and then burnt to perform work. The lubricating phase is carried out alternately between the diesel injection phase and the natural gas injection phase.

[0040] Therefore, the implementation method can be divided into three stages:

[0041] The first stage, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com