A supporting cutting section for cross-connecting shaft-type fully mechanized mining in extremely thin coal seams

A technology of ultra-thin coal seam and cutting section, which is applied in the field of supporting cutting section for ultra-thin coal seam cross-connecting shaft-type fully mechanized mining, can solve the problems of large space-time top distance, long cutting section dimension, and difficult cooling, etc. The degree of automation, the effect of increasing social benefits and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

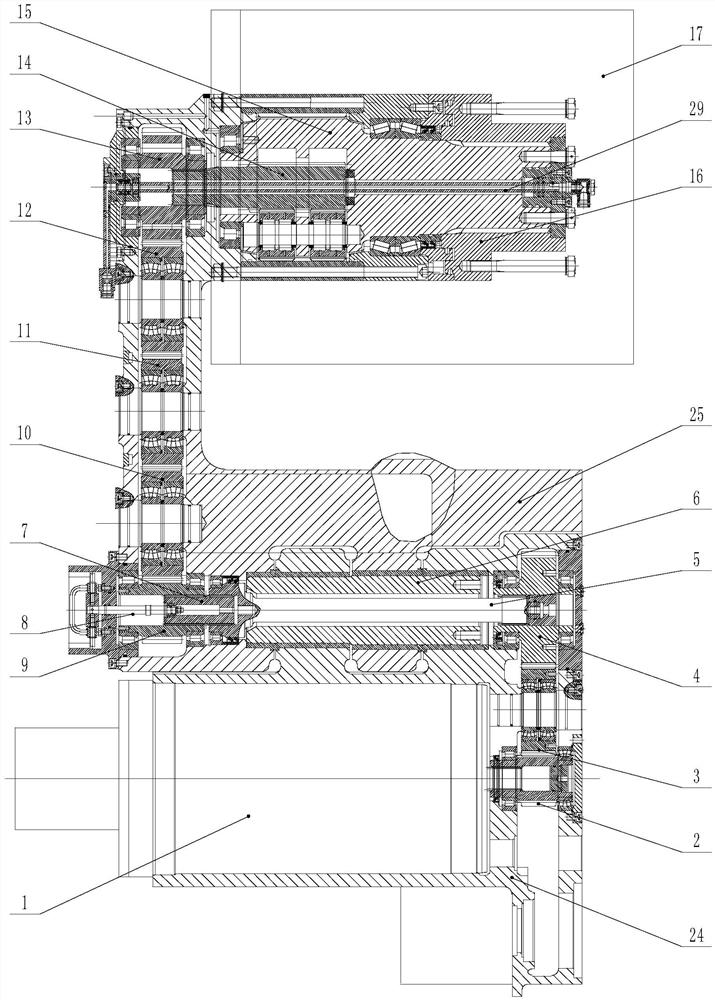

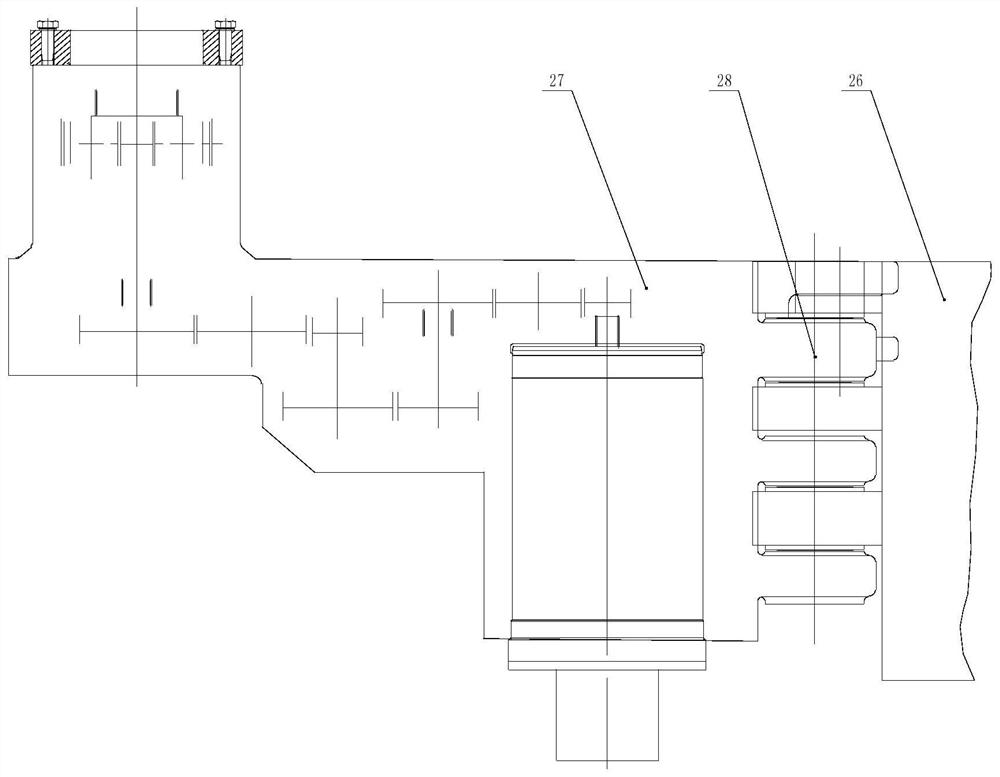

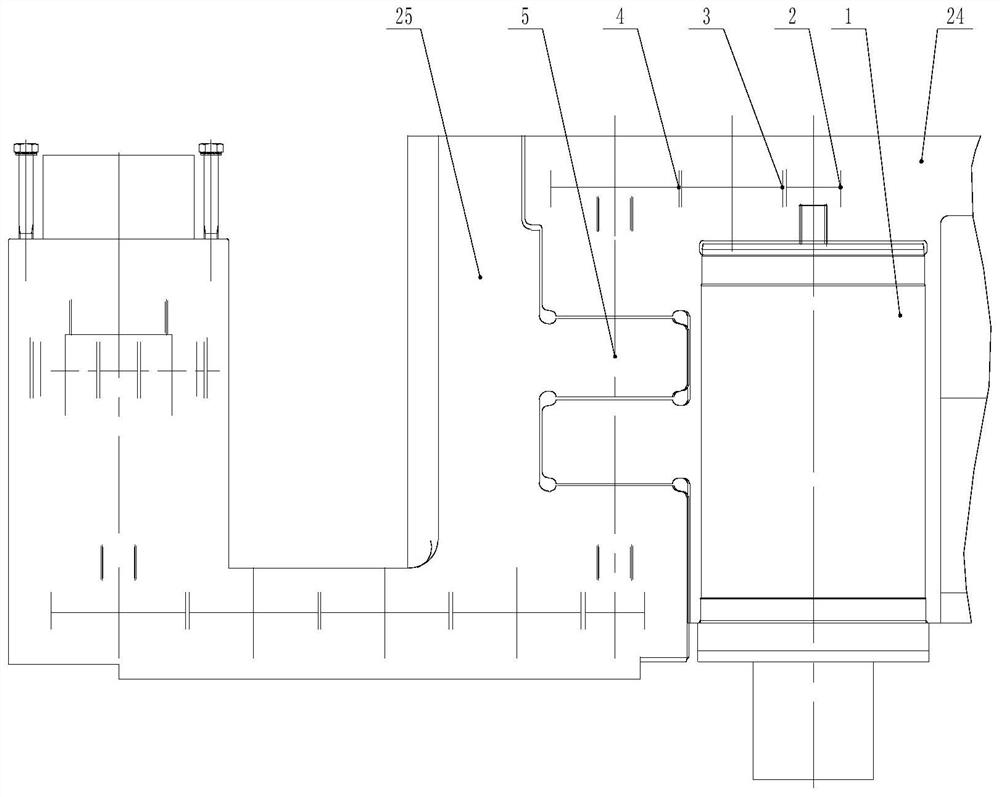

[0017] like figure 1 As shown in the figure, an ultra-thin coal seam cross-connection shaft type fully mechanized mining matching cutting part, the drive motor 1 on the traction part 24 is fixedly connected with the first-stage shaft gear 2 through splines, and the first-stage shaft gear 2 passes through the first idler gear. The wheel 3 meshes with the first-stage large gear 4, the first-stage large gear 4 is connected with the first spline shaft 5 through splines, and the first spline shaft 5 is connected with one end of the clutch second spline shaft 7 through splines, The other end of the clutch second spline shaft 7 is fixedly connected with the reduction pinion 9 through the internal spline, the reduction pinion 9 meshes with the third idler 11 through the second idler gear 10, and the third idler 11 through the fourth idler gear 12 meshes with the end gear 13, the end gear 13 transmits the power to the center wheel 14 of the planetary mechanism through the spline, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com