Method and device for hydrolysis pulping in transcritical CO2 reaction system

A reaction system and transcritical technology, applied in the field of papermaking and pulping, can solve problems such as waste of plant resources and environmental pollution, and achieve the effects of improving thermal power efficiency, reducing effective energy loss, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

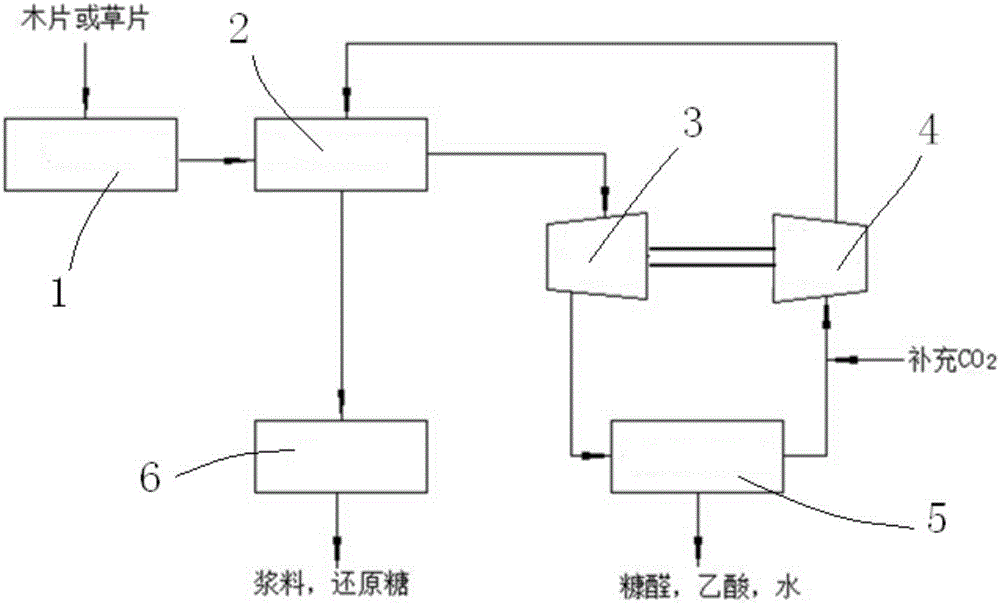

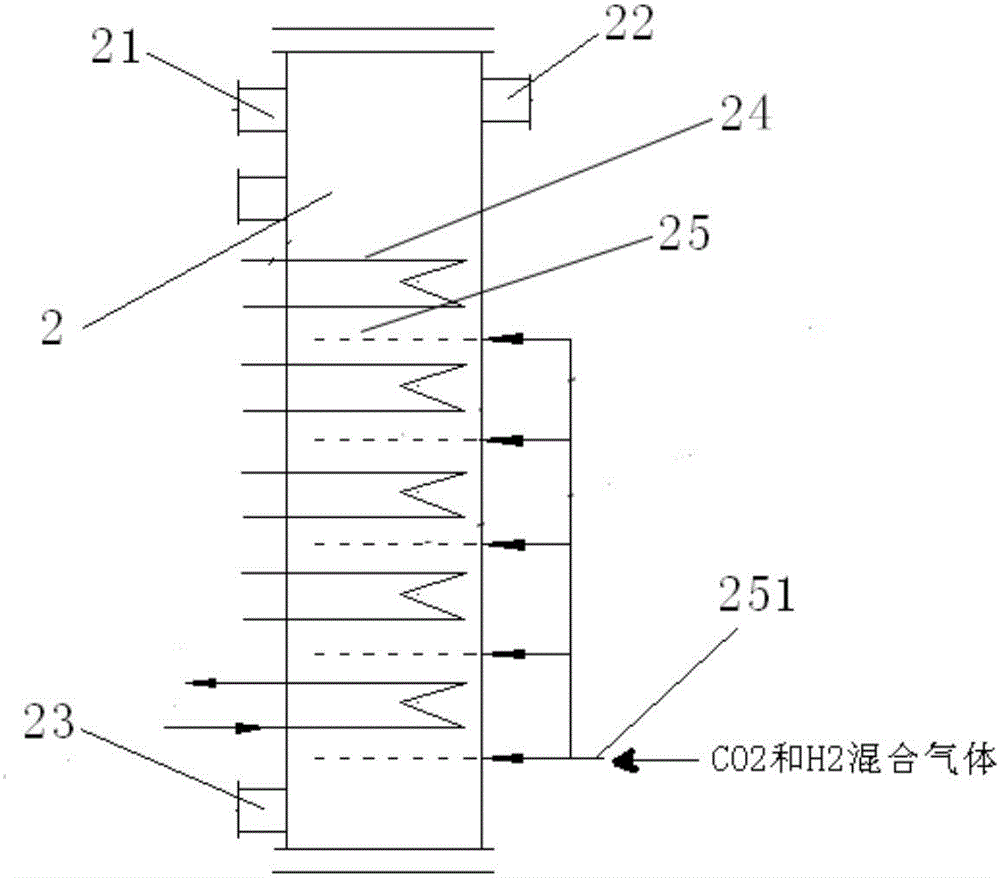

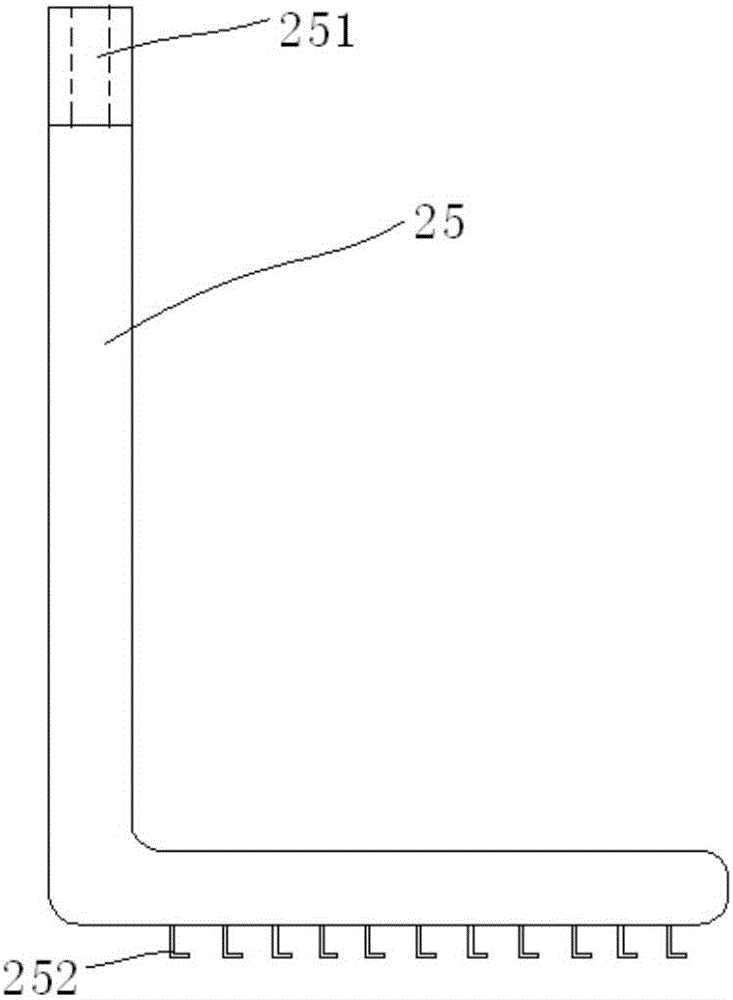

[0038] Such as Figure 1 to Figure 4 As shown, the device for hydrolysis pulping in the transcritical CO2 reaction system includes: a preprocessor 1, a reactor 2, an expander 3, a turbocompressor 4, a gas-liquid separator 5, and a blower 6.

[0039] The discharge port of the preprocessor 1 is connected with the feed port of the reactor 2, and the preprocessor 1 is used for heating and pretreating the raw materials required for production. The reactor 2 is cylindrical. The upper part of the reactor is provided with a feed inlet 21 and a gas outlet 22, and the bottom is provided with a feed outlet 23. The reactor 2 includes a heating pipe 24, which is a heating coil, which is located inside the reactor. a gas distributor 25, which includes an air inlet 251 and a plurality of nozzles 252 for exhaust; the expander 3 is connected to the gas outlet of the reactor 2. The turbocompressor 4 is connected to the expander 3 , and the turbocompressor 4 is driven to work by the expander 3 ...

Embodiment 2

[0048] The reaction device that uses is identical with embodiment 1, a kind of transcritical CO The method for hydrolysis pulping of reaction system comprises the following steps:

[0049] (1) Prepare the raw materials, mix water and bagasse in a mass ratio of 200:1, and then preheat;

[0050] (2) Hydrolysis reaction, put the mixture prepared in step (1) into the reactor, heat up to 300°C, and fill the reactor with CO 2 , the temperature in the reactor is 300°C, and the pressure is 15MPa;

[0051] (3) Take out the mixed gas after reaction in the reactor, the mixed gas contains CO 2 , water vapor, furfural and acetic acid, the flow rate of the mixed gas taken out from the reactor is 0~10000m 3 / h, when the gas flow rate is 0, no gas flows out. Pass the gas through the expander, expand and reduce the pressure to 0~1.0MPa, cool down to 20℃~30℃, enter the gas-liquid separator for separation, the temperature of the gas-liquid separator is 10~20℃, and the pressure is 0.0~ 1.0MPa...

Embodiment 3

[0054] The reaction device that uses is identical with embodiment 1, a kind of transcritical CO The method for hydrolysis pulping of reaction system comprises the following steps:

[0055] (1) Prepare the raw materials, mix water and bagasse in a mass ratio of 70:1, and then preheat;

[0056] (2) Hydrolysis reaction, put the mixture prepared in step (1) into the reactor, heat up to 500°C, and fill the reactor with CO 2 , the temperature in the reactor is 500°C, and the pressure is 30MPa;

[0057] (3) Take out the mixed gas after reaction in the reactor, the mixed gas contains CO 2 , water vapor, furfural and acetic acid, the flow rate of the mixed gas taken out from the reactor is 0~10000m 3 / h, when the gas flow rate is 0, no gas flows out. Pass the gas through the expander, expand and reduce the pressure to 0~1.0MPa, cool down to 20℃~30℃, enter the gas-liquid separator for separation, the temperature of the gas-liquid separator is 10~20℃, and the pressure is 0.0~ 1.0MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com