Aluminum-tungsten-niobium three-element intermediate alloy and preparation method thereof

A master alloy and three-element technology, which is applied in the field of aluminum-tungsten-niobium three-element master alloy and its preparation, can solve the problems of increasing refractory and easy segregation, and high cost of preparation and storage of pure tungsten powder, so as to improve stability, ensure composition and Its uniformity and the effect of avoiding the instability of melting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the above-mentioned aluminum-tungsten-niobium three-element master alloy comprises the following steps:

[0020] A. Take Al, WO 3 , Nb 2 o 5 As a raw material, after mixing according to 50-90wt%: 30-55wt%: 25-55wt%, the aluminum-tungsten-niobium three-element master alloy ingot is obtained through the aluminothermic reaction;

[0021] B. The above-mentioned master alloy ingot is finished, crushed and selected to make master alloy products with a particle size of 0.25-6mm, and its composition includes 25-40wt% of W, 20-35wt% of Nb, 0-0.3wt% of Trace elements, the balance is Al.

[0022] And adopt the master alloy product of the present invention to be used for the smelting method of high Nb-TiAl intermetallic compound ingot, comprise the following steps:

[0023] A. The composition contains 25-40wt% W, 20-35wt% Nb, 0-0.3wt% trace elements, the balance is Al, and the aluminum-tungsten-niobium three-element master alloy product with a parti...

Embodiment 1

[0027] High Nb-TiAl alloy:

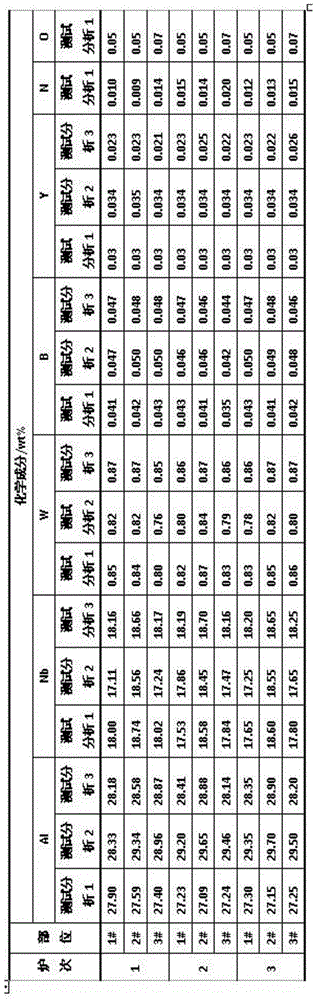

[0028] The standard nominal composition is Ti-28.56Al-18.575Nb-0.87W-0.051B-0.042Y (by weight percentage: wt%).

[0029] Take Al, WO 3 , Nb 2 o 5 As raw material, according to Al:WO 3 :Nb 2 o 5 = 70.5wt%: 37.19wt%: 37.67wt% After the proportioning and mixing, the aluminum-tungsten-niobium three-element intermediate alloy ingot is obtained through the aluminothermic reaction, and the intermediate alloy with a particle size of 0.25mm is made through finishing, crushing, and selection. alloy products. The composition of the master alloy product is W: 29.48wt%, Nb: 26.33wt%, C: 0.018wt%, N: 0.015wt%, O: 0.066wt%, Al: the balance. After the master alloy product is mixed with sponge titanium, Al-Nb, Al-Ti-B and Al wire master alloy raw materials according to the ratio of 2.69:52.08:25.43:4.55:15.72 (wt%), after raw material stirring, mold cloth and High Nb-TiAl intermetallic compound electrodes for plasma-cooled hearth furnaces are made by extrus...

Embodiment 2

[0031] High Nb-TiAl alloy:

[0032] The standard nominal composition is Ti-28.56Al-18.575Nb-0.87W-0.051B-0.042Y (by weight percentage: wt%).

[0033] Take Al, WO 3 , Nb 2 o 5As a raw material, after mixing according to Al:WO3:Nb2O5=57.2:43.5:42.3 (wt%), according to the method of Example 1, a master alloy product with a particle size of 6mm was produced. The composition of the master alloy product is: W: 34.39wt%, Nb: 29.56wt%, C: 0.021wt%, N: 0.014wt%, O: 0.062wt%, Fe: 0.063wt%, Si: 0.047wt%, Al :margin. After the master alloy product is mixed with sponge titanium, Al-Nb, Al-Ti-B and Al wire master alloy raw materials according to the ratio of 2.55:52.5:25.4:4.57:15.87 (wt%), after raw material stirring, mold cloth and High Nb-TiAl intermetallic compound electrodes for plasma-cooled hearth furnaces are made by extrusion and other steps, and the composition is Ti-27.19Al-17.98Nb-0.84W-0.043B-0.03Y (according to Weight percentage: wt%) high Nb-TiAl intermetallic compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com