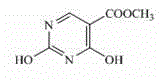

Preparation method of 2,4-dyhydroxyl-5-pyrimidinecarboxylic acid

A technology of pyrimidinecarboxylic acid and dimethyl methoxymethylenemalonate, which is applied in the field of preparation of important organic synthesis intermediate 2,4-dihydroxy-5-pyrimidinecarboxylic acid methyl ester, and can solve problems such as unpublished , to achieve the effect of easy-to-obtain raw materials, simple operation process and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

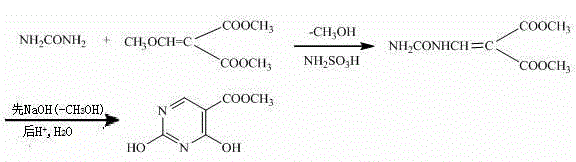

[0018] Synthesis of Dimethyl Methoxymethylene Malonate by Condensation Reaction

[0019] Add 34.8g (0.2mol) of dimethyl methoxymethylenemalonate and 14.4g (0.24mol) of urea into a four-necked flask, add 200mL of ethanol as a solvent, and start stirring to dissolve. Add 3.9g (0.04mol) of sulfamic acid as a catalyst to the four-neck flask, heat and reflux for 5 hours, distill off the solvent, cool, vacuum filter, rinse the filter cake with ice water for several times, at 80°C Dry to constant weight. 25.6 g of white solid ureidomethylene malonate dimethyl was obtained, the yield was 63.37%, m.p.227~230°C.

[0020] Synthesis of methyl 2,4-dihydroxy-5-pyrimidinecarboxylate from ureidomethylenemalonate through ring-closing reaction

[0021] Take 20.2 g (0.1 mol) of ureidomethylene malonate dimethyl ester obtained in the above steps and 160 mL of 10% NaOH solution, heat up to 95 ° C for 2 hours, stop heating, cool to room temperature, and wash with 20% HCl The solution was fir...

Embodiment 2

[0023] Synthesis of Dimethyl Methoxymethylene Malonate by Condensation Reaction

[0024] Add 34.8g (0.2mol) of dimethyl methoxymethylenemalonate and 14.4g (0.24mol) of urea into a four-necked flask, add 200mL of ethanol as a solvent, and start stirring to dissolve. Add 5.8g (0.06mol) of sulfamic acid as a catalyst to a four-neck flask, heat and reflux for 5 hours, distill off the solvent, cool, vacuum filter, rinse the filter cake with ice water for several times, at 80°C Dry to constant weight. 26.5 g of white solid ureidomethylene malonate dimethyl was obtained, the yield was 65.59%, m.p.227~230°C.

[0025] Synthesis of methyl 2,4-dihydroxy-5-pyrimidinecarboxylate from ureidomethylenemalonate through ring-closing reaction

[0026] Take 20.2 g (0.1 mol) of ureidomethylene malonate dimethyl ester obtained in the above steps and 160 mL of 10% NaOH solution, heat up to 95 ° C for 2 hours, stop heating, cool to room temperature, and wash with 20% HCl The solution was first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com