Cement-based reinforcing grouting material with strong acid resistance

A cement-based, grouting material technology, applied in the field of building materials, can solve the problems of low compressive strength, short service life, poor fluidity, etc., and achieve the effect of reducing permeability and enhancing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Select 100 kg of PO42.5 Portland cement, 50 kg of Class I fly ash, 20 kg of phenylacrylic acid-resistant rubber powder, 10 kg of naphthalene-based high-efficiency water reducer, 300 kg of machine-made sand, 20 kg of UEA expansion agent, methyl 0.5 kg of cellulose ether.

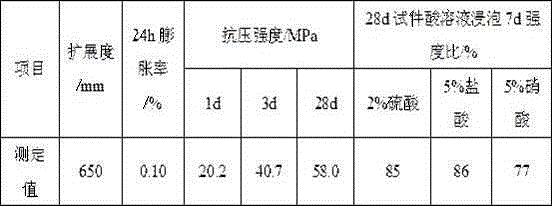

[0019] Weigh each component according to the above ratio, mix in a forced mixer for 15-20 minutes, and store in dry bags. When in use, add drinking water with 12% of the mass of the mixture and stir. The performance of the grouting material is as follows:

[0020]

Embodiment 2

[0022] Select 100 kg of PO42.5 Portland cement, 35 kg of mineral powder, 25 kg of modified rubber chloroprene acid-resistant rubber powder, 5 kg of polycarboxylate superplasticizer, 260 kg of quartz sand, UEA and nitroso mixed expansion agent 15 kg, 1 kg of hydroxyethyl cellulose ether.

[0023] Weigh each component according to the above ratio, mix in a forced mixer for 15-20 minutes, and store in dry bags. When in use, add drinking water with 10% of the mass of the mixture and stir. The performance of the grouting material is as follows:

[0024]

Embodiment 3

[0026] Select 100 kg of PO42.5 Portland cement, 10 kg of silica fume, 20 kg of fly ash, 30 kg of vinyl acetate-chloroprene rubber copolymer powder, 3 kg of polycarboxylate superplasticizer, 200 kg of gravel, UEA 10 kg of expansion agent, 0.2 kg of hydroxypropyl cellulose ether.

[0027] Weigh each component according to the above ratio, mix in a forced mixer for 15-20 minutes, and store in dry bags. When in use, add drinking water with 10% of the mass of the mixture and stir. The performance of the grouting material is as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com