Method for preparing active carbon with high specific surface area by utilizing activated abandoned bakelite

A high specific surface area, activated carbon technology, applied in the field of resource recycling, can solve the problems of increasing the number of bakelite, secondary pollution, resource consumption, etc., and achieve the effects of reducing production costs, saving time, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

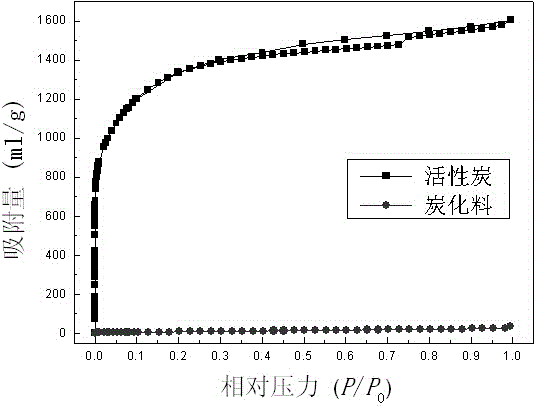

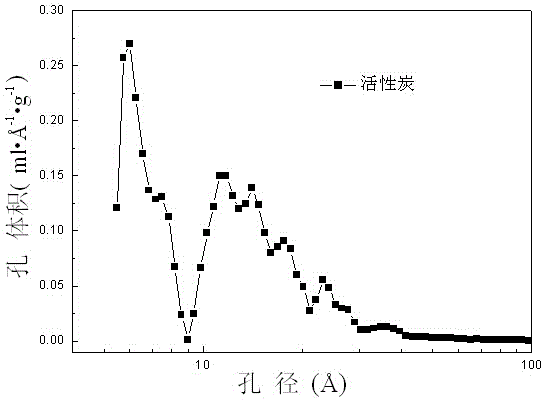

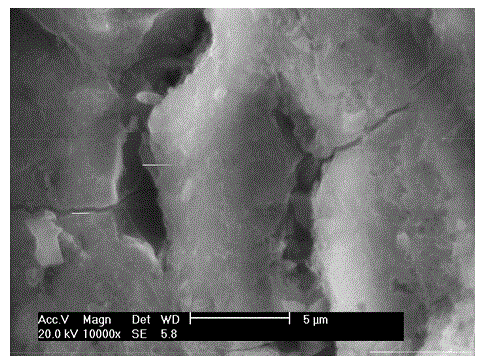

[0028] Firstly, the waste bakelite was crushed to a particle size of 500 meshes, and then KOH and waste bakelite were mixed in a solid state at a mass ratio of 2.0:1 and evenly loaded into a ceramic crucible and placed in a microwave high-temperature reaction furnace. Blow nitrogen into the furnace for 1.0 min to evacuate the air in the furnace, heat for 24 min under the condition of microwave power 5kW, and when the heating reaches 18 min, quickly inject water vapor for 3.0 min through the tube connected to the bottom of the ceramic crucible, and open it at the same time 100W ultrasonic generator, turn off the microwave device and ultrasonic generator after heating, remove the material to obtain the activated material and quickly transfer the activated material to a container with tap water, first wash with water, and recover the residual KOH activator; then use hydrochloric acid Pickling was carried out, and then the sample after pickling was rinsed with tap water to keep the...

Embodiment 2

[0032] Firstly, the waste bakelite was crushed to a particle size of 800 meshes, and then KOH and waste bakelite were mixed in a solid state at a mass ratio of 1.5:1 and evenly loaded into a ceramic crucible and placed in a microwave high-temperature reaction furnace; blown into the furnace for 1.5 min Nitrogen is used to evacuate the air in the furnace, and it is heated for 27 minutes under the condition of microwave power 8kW. Turn off the microwave device and the ultrasonic generator, remove the material to obtain the activated material and quickly transfer the activated material to a container with tap water, first wash it with water, and recover the residual KOH activator. Pickling was carried out with hydrochloric acid, and then the sample after pickling was rinsed with tap water to keep the pH value of the solution at 7, and dried at 105° C. for 2 hours to obtain activated carbon with a high specific surface area.

[0033] The iodine adsorption value of the high specific ...

Embodiment 3

[0035] Firstly, the waste bakelite was crushed to a particle size of 600 meshes, and then KOH and waste bakelite were mixed in a solid state at a mass ratio of 1.0:1 and evenly loaded into a ceramic crucible and placed in a microwave high-temperature reaction furnace. Blow nitrogen into the furnace for 2.0 minutes to evacuate the air in the furnace, heat for 30 minutes under the condition of microwave power of 10kW, and when the heating reaches 20 minutes, quickly pass in water vapor for 4.0 minutes through the tube connected to the bottom of the ceramic crucible, and open at the same time 300W ultrasonic generator, turn off the microwave device and ultrasonic generator after heating, remove the material to obtain the activated material and quickly transfer the activated material to a container filled with tap water, first wash with water, and recover the residual KOH activator. Then use hydrochloric acid to pickle, then rinse the sample after pickling with tap water, keep the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com