A method for rapidly preparing high-performance graphene

A graphene and high-performance technology, which is applied in the field of rapid preparation of high-performance graphene, can solve the problems of reduced small molecule gas, poor graphene quality, and reduced stripping rate, achieving high energy utilization, high production efficiency, and no The effect of thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

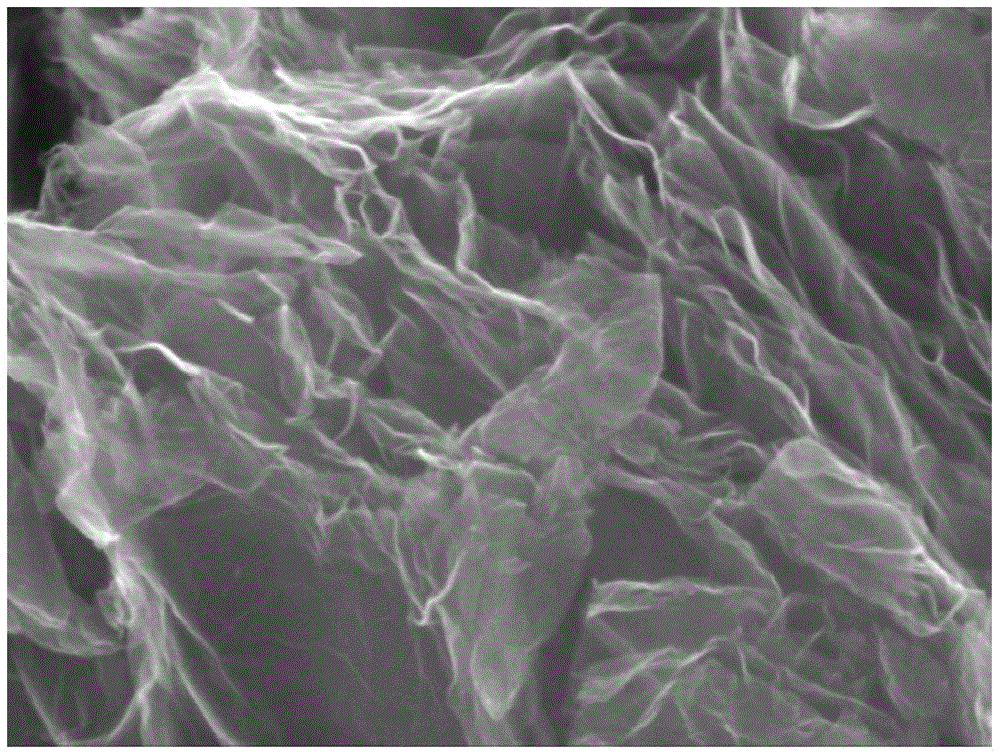

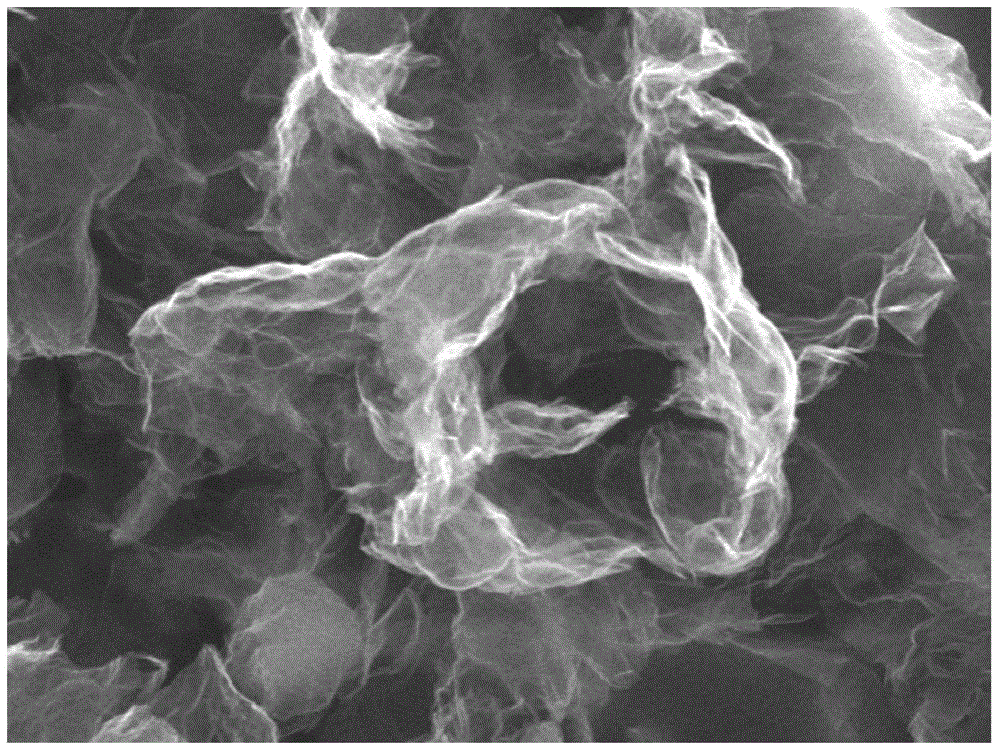

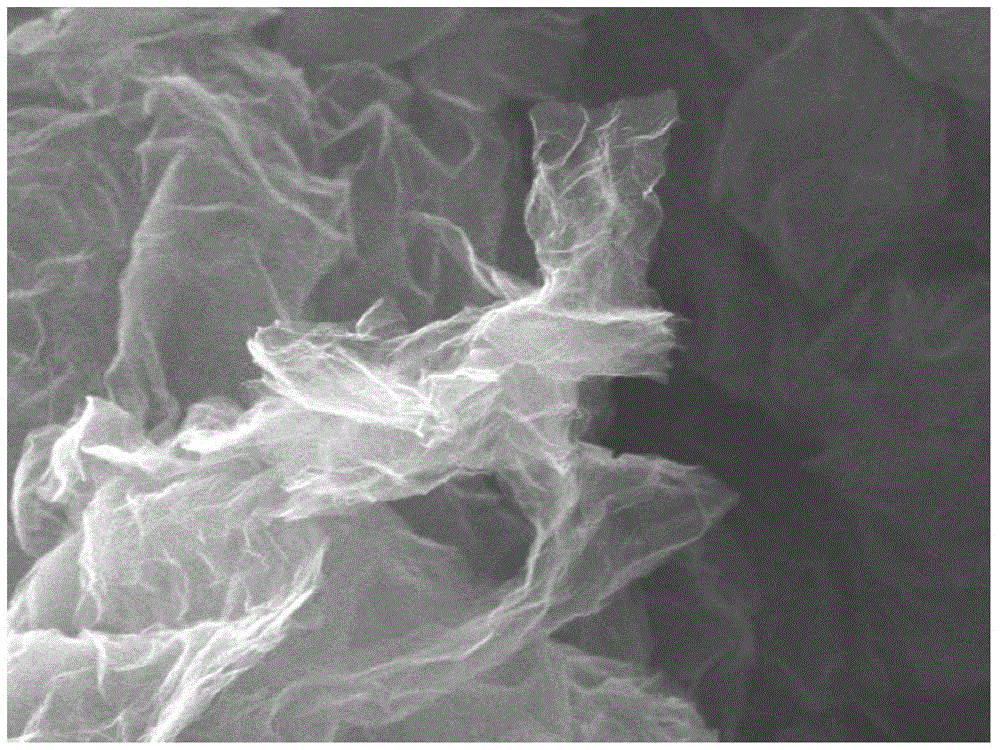

[0029] Graphite oxide was prepared by the Hummers method, 1 g of the prepared graphite oxide was placed in the reactor, the reactor was pumped to 1000 Pa, and the microwave was turned on, the microwave frequency was 100 MHz, and the power and time were as follows: the first section: 10 W, 10 s; second stage: 100 W, 10 s; third stage: 800 W, 10 s. After three-stage microwave radiation treatment, graphite oxide was successfully exfoliated and reduced to graphene, and the specific surface area of graphene was measured by nitrogen adsorption-desorption method to be 600 m 2 / g.

Embodiment 2

[0031] Graphite oxide was prepared by the improved Hummers method, 1 g of the prepared graphite oxide was placed in the reactor, the reactor was pumped to 0.01 Pa, and the microwave was turned on, the microwave frequency was 500 GHz, and the power and time were as follows: the first section: 60 W , 60 s; second stage: 600 W, 60 s; third stage: 1000 W, 60 s. After three-stage microwave radiation treatment, graphite oxide was successfully exfoliated and reduced to graphene, and the specific surface area of graphene was measured by nitrogen adsorption-desorption method to be 2000 m 2 / g.

Embodiment 3

[0033] Graphite oxide was prepared by the Brodie method, 1 g of the prepared graphite oxide was placed in the reactor, the reactor was pumped to 500 Pa, and the microwave was turned on, the microwave frequency was 800 MHz, and the power and time were as follows: the first section: 20 W, 30 s; second stage: 300 W, 10 s; third stage: 800 W, 15 s. After three-stage microwave radiation treatment, graphite oxide was successfully exfoliated and reduced to graphene, and the specific surface area of graphene was measured by nitrogen adsorption-desorption method to be 820 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com