Hole metallization method based on laser activation technology

A technology of hole metallization and laser activation, which is applied to the formation of electrical connections of printed components, electrical components, and printed circuit manufacturing. It can solve the problems of affecting the quality of the coating, the degree of treatment is difficult to control, and the service life is reduced, so as to achieve good adhesion of the coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

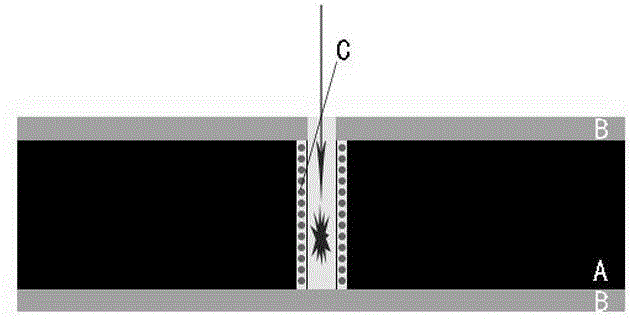

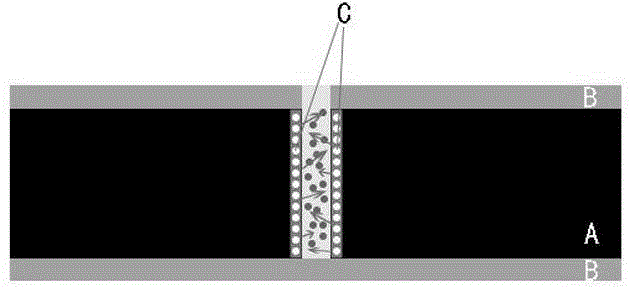

[0036] The double-sided copper-clad soft board is used as the base material, and blind hole metallization is realized to achieve the purpose of electrical connection.

[0037] (1) Select the polyimide double-sided copper-clad laminate commonly used in the market, which is mechanically processed and has excellent flexibility, as the base material, and cut it into a size suitable for processing.

[0038] (2) Put the material in the laser processing equipment. After the equipment enters the laser operation file, laser drilling is performed on the copper clad laminate (hereinafter referred to as the drilled hole is a micro hole, the same as in the second embodiment), and the laser irradiation is adjusted at the same time to make the surface form nanoscale pores. The laser irradiation pulse energy is controlled at 60-70 mJ, the focus height is controlled at 1.8 mm, the laser frequency is controlled at 50-60 kHz, the laser pulse width is controlled at 102-120 nms, and the beam diame...

Embodiment 2

[0047] The impregnated well-known glass fiber is used as the base material, and the metallization of the blind hole is realized to achieve the purpose of electrical connection.

[0048] (1) Select FR4, which is commonly used in the market and has excellent mechanical properties, as the base material, and cut it into a size suitable for processing.

[0049] (2) Put the material in the laser processing equipment. After the equipment enters the laser operation file, laser drilling is performed on the copper clad laminate, and the laser irradiation is adjusted at the same time to form nano-scale holes on the surface. The pulse energy of the laser irradiation meter is controlled at 100-125 mJ, the focus height is controlled at 10-30 mm, the laser frequency is controlled at 48-60 kHz, the laser pulse width is controlled at 102-120 nm, and the beam diameter is controlled at 15-20 mm.

[0050] (3) Put the drilled substrate into the plasma cleaning equipment to clean the tiny holes on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com