Wind power bus jointing element

A technology for connecting components and wind power busbars, which is applied in the field of tubular wind power busbar connecting components, can solve problems affecting work efficiency, potential safety hazards, easy loosening, etc., achieve efficient and easy installation and disassembly, strengthen connection effects, and prevent bolts from loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

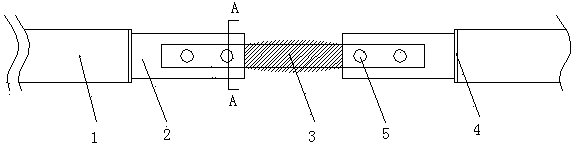

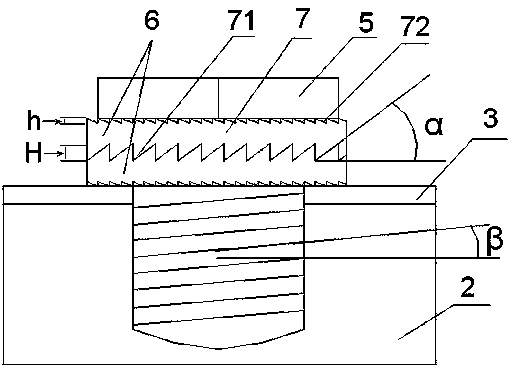

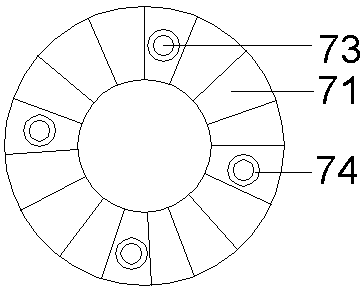

[0016] As shown in the figure, a wind power bus connecting member includes two sections of tubular conductors 1 to be connected, a joint 2 and a soft connection 3, and there is a connecting plane 4 at the bottom, and the connecting plane 4 is welded to the joint 2 by welding As a whole, the soft connection 3 is fixedly connected to the joint 2 through the bolt 5, wherein a lock washer 6 is provided between the bolt 5 and the joint 2, and the lock washer 6 is composed of a pair of gaskets 7, the gasket 7 is a hollow circle structure, the occlusal surface 71 and the non-contact surface 72 of the gasket are provided with divergent serrations, and the number of serrations on the non-contact surface 72 is larger than that of the occlusal surface. The number of serrations on the surface 71, the depth h of the serrations on the non-contact surface 72 is smaller than the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com