Connecting structure for vacuum arc-extinguishing chamber moving contact and conductive holder

A vacuum interrupter and connection structure technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of reducing the current carrying capacity of the conductive circuit, the large contact resistance of the conductive circuit, and the high temperature rise value, so as to improve the current carrying capacity of the conductive circuit, The effect of reducing the resistance of the conductive loop and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution will be further described below in conjunction with the accompanying drawings.

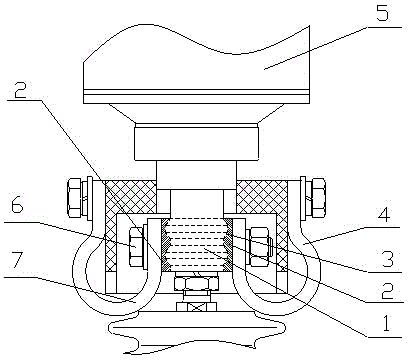

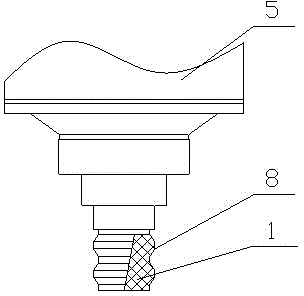

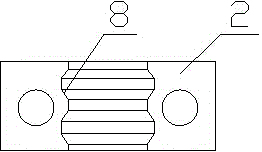

[0013] Such as figure 1 As shown, a connection structure between the movable contact of the vacuum interrupter and the conductive clip, the structure is that the contact surface between the movable contact 1 of the vacuum interrupter and the conductive clip 2 is a tooth-shaped meshing surface 3, and the vacuum interrupter The moving contact and the conductive clip are tooth-shaped bite contacts.

[0014] The conductive clip 2 is divided into two pieces, A conductive clip and B conductive clip. When in use, A conductive clip and B conductive clip are used in conjunction with each other. The connection relationship between the conductive clip 2 and the moving contact 1 of the vacuum interrupter is from left to right The left flexible connection 7, A conductive clip, vacuum interrupter movable contact 1, B conductive clip, right flexible connection 4, and the standard p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com