Aluminum conductor for overhead conductor

An overhead wire, aluminum conductor technology, applied in the direction of metal/alloy conductors, etc., can solve the problems such as the conductivity is not improved, the aluminum conductor is not suitable for large-span overhead wires, and the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

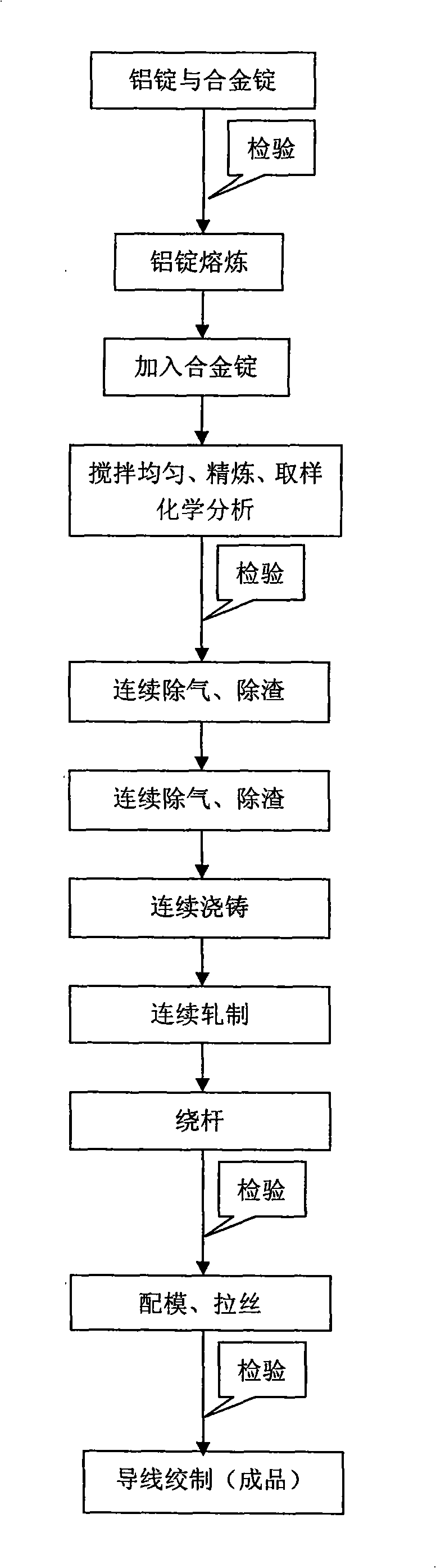

Method used

Image

Examples

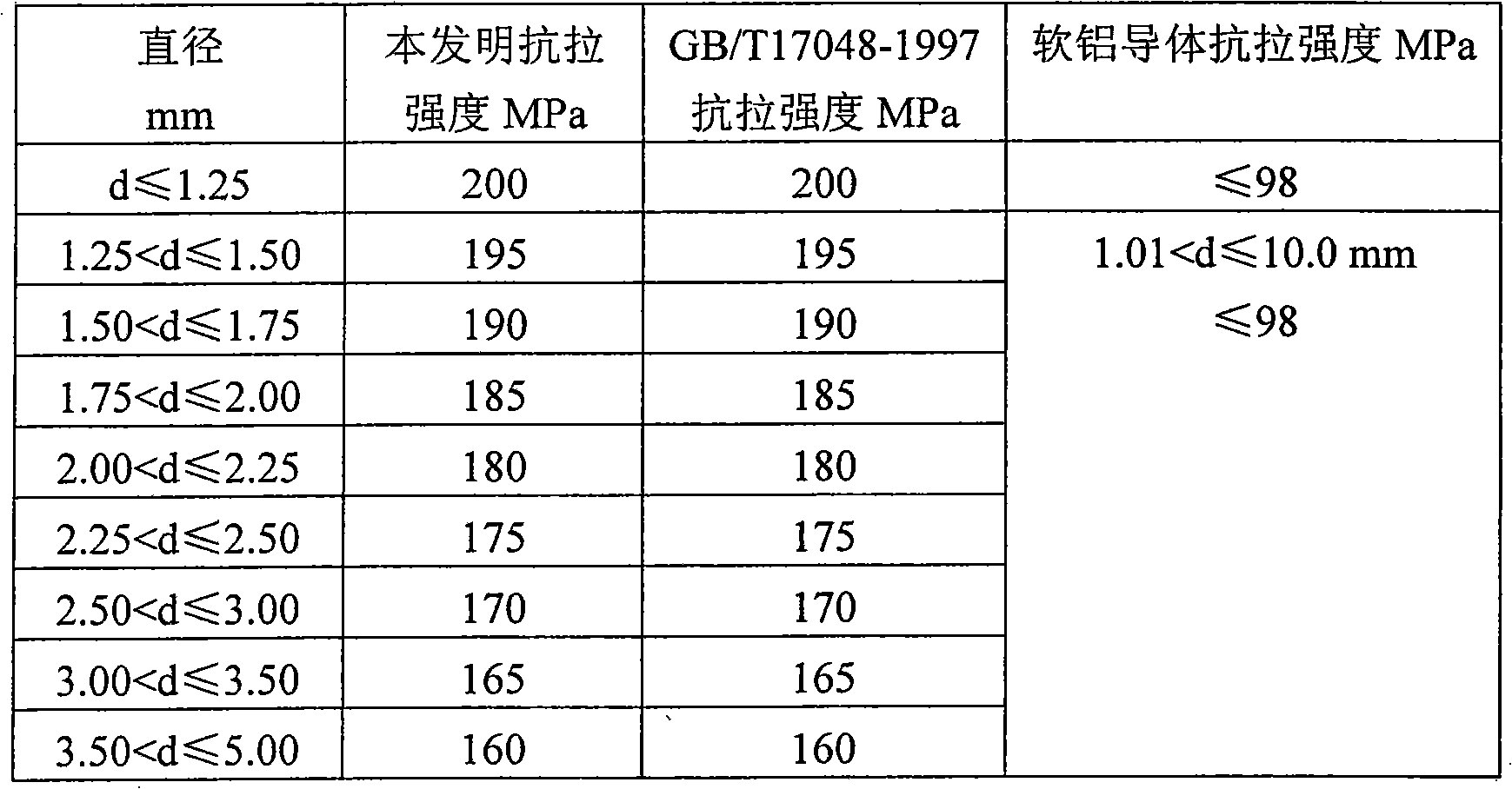

Embodiment 1

[0023] Embodiment 1: according to accompanying drawing process, check raw material, select the brand AL99.85A aluminum ingot (composition is shown in Table 3) for use, put into melting in the aluminum ingot smelting furnace, add the iron-aluminum alloy of 0.03wt% (the brand is AlFe20), 0.02 wt% boron aluminum alloy (brand is AlB3). After uniform stirring, scouring and degassing, sampling analysis (depending on the results to determine whether to add materials), slag removal, refining temperature 740-750 ° C, refining time 8-12 minutes, standing time 15 minutes, (before furnace chemical rapid analysis, Monitor and control the content of elements, see Table 4) and then cast, the casting temperature is 700-710°C, and the rolling temperature is about 500°C, rolled into an aluminum rod of ¢12.0mm, and drawn on a high-speed wire drawing machine at 16 m / s Speed, with 7 dies for drawing ¢3.99mm aluminum wire. The impurity content and properties of aluminum wire conductors are shown i...

Embodiment 2

[0024]Embodiment 2: according to accompanying drawing process, test raw material, select the brand AL99.70A aluminum ingot for use (composition sees Table 3). Put it into an aluminum melting furnace for melting, add 0.05wt% lanthanum-rich rare earth aluminum alloy, and add 0.04wt% boron aluminum alloy (the brand is AlB3). After uniform stirring, refining degassing, and slag removal, the refining temperature is 740-750°C, the refining time is 8-12 minutes, and the standing time is 15 minutes. Casting, the casting temperature is 700-710°C, the rolling temperature is controlled at about 500°C, and rolled into an aluminum rod of ¢12.0mm. On a high-speed wire drawing machine, the drawing speed is 16 m / s, and the mold is equipped with 7 molds for drawing ¢3.99 mm aluminum wire. The impurity content and properties of aluminum wire conductors are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com