126-kv cabinet type gas-insulated metal-closed switching equipment

A gas-insulated metal, closed switchgear technology, applied in switchgear settings, switchgear, substation/switchgear board/panel/desk, etc. It can eliminate the problems of interphase insulation stress, reduce the difficulty of use and maintenance, and improve reliability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

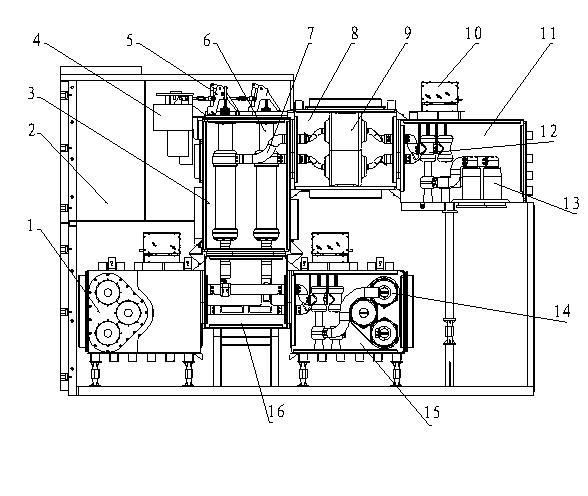

[0048] Such as figure 1As shown, the present invention adopts a modular design, including a cabinet shell 2, a vacuum circuit breaker compartment 3, a vacuum circuit breaker driving mechanism conversion device 5, a current transformer compartment 8, and a current transformer installed in the current transformer compartment 8 Transformer 9, cable connection compartment 11, bus confluence compartment 16 and two bus bars and three-position isolating switch compartment 15, in the compartment between cable connection compartment 11 and two bus bars and three-position isolating switch compartment 15 Install a three-station isolating switch 12 indoors, and install a three-station isolating switch drive mechanism 10 on the outer top of the cable connecting compartment 11 and two busbars and the three-station switch compartment 15 to realize the opening of the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com