Speed reducer of novel conveyor

A conveyor and reducer technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of small power-to-weight ratio, large transmission ratio, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

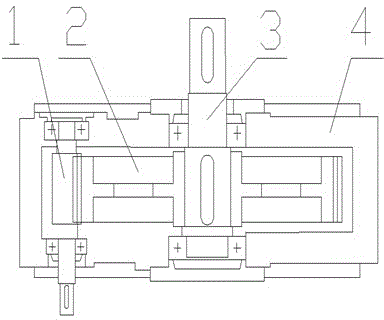

[0009] Such as figure 1 As shown, the present invention is a new type of conveyor reducer, including worm (1), turbine (2), output shaft (3), box (4); input torque drives worm (1) to rotate, turbine (2) and The worm (1) meshes, the turbine (2) is installed on the output shaft (3), and the output shaft (3) outputs torque under the drive of the turbine (2), the worm (1) and the output shaft (3) are in the box ( 4) above.

[0010] The above-mentioned new type of conveyor reducer is characterized in that the coal mine conveyor adopts an involute gear transmission mechanism with a small number of teeth, which increases the transmission ratio of a single machine, reduces the structural size and volume, and has low cost, simple structure, It has the advantages of high transmission efficiency, large load-carrying capacity, anti-wear and strong glue-resistance.

[0011] When in use: the input torque drives the worm to rotate, and the worm gear meshes with the worm to form an involute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com