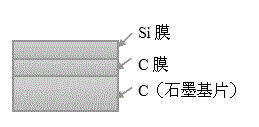

Preparation process of novel C/Si film

A preparation process, a new type of technology, applied in the field of preparation process of new C/Si film, can solve the problems of micropipe defects that cannot be eliminated, difficult doping, expensive SiC bulk single crystal, etc., to increase the structure and chemical order, The effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the experiment, graphite flakes were used as the substrate material with a purity of 99.99% and a size of 20mm×10mm×2mm. Before the experiment, the graphite substrate was polished and pretreated, and then cleaned. The process is as follows:

[0012] (1) Use #1-#6 sandpaper to polish the surface of the graphite sheet to keep the surface smooth;

[0013] (2) Wash the polished sample in 30% nitric acid for 10 minutes to remove surface impurities;

[0014] (3) Take out the sample and wash it in acetone for 10 minutes to remove the oil on the surface;

[0015] (4) Take out the sample and wash it in ethanol for 10 minutes to dissolve the organic matter on the surface;

[0016] (5) Wash the treated samples in deionized water until neutral, then take them out and dry them for later use.

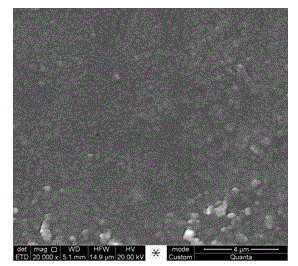

[0017] A new type of C / Si film preparation process, including the following steps: the graphite substrate is fixed in the sputtering chamber of magnetron sputtering, the target material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com