Recombinant escherichia coli for preparing (S)-4-chlorine-3-hydroxyl ethyl butyrate by adopting asymmetric transformation and application of recombinant escherichia coli

A technology of recombinant Escherichia coli and ethyl hydroxybutyrate, applied in the field of enzyme catalysis, can solve the problems of large pollution, low yield, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

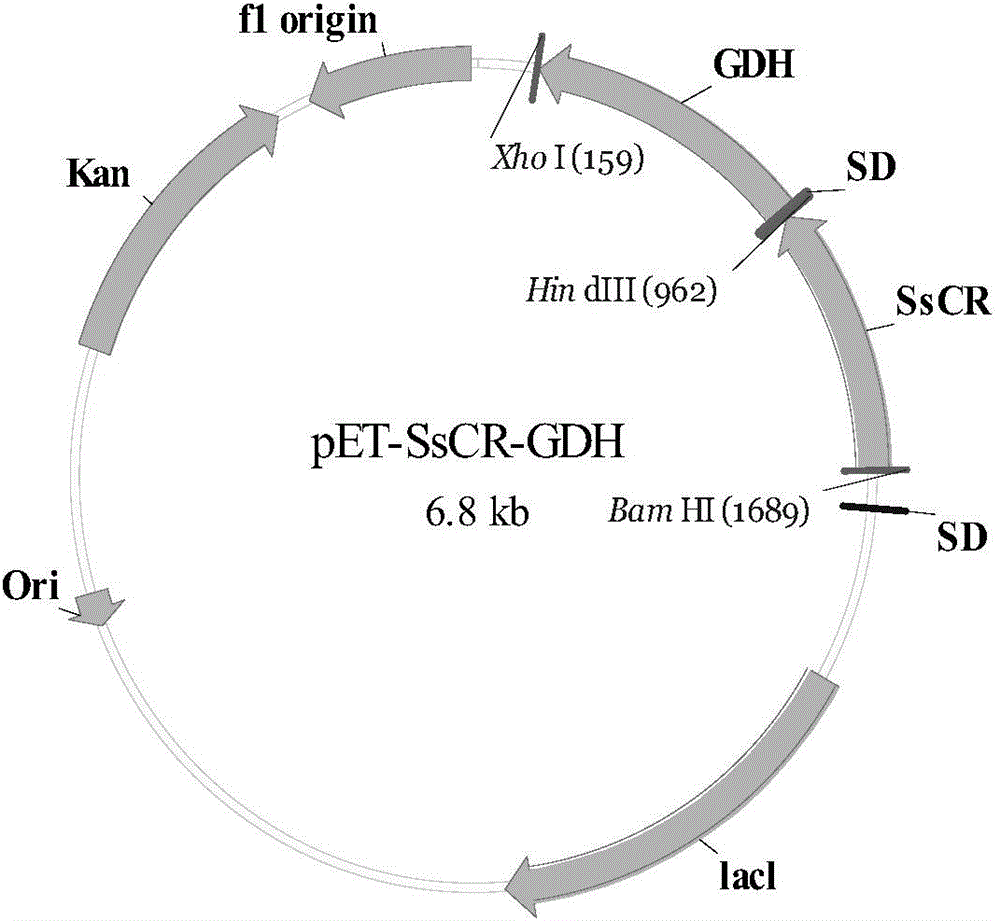

[0027] Embodiment 1: Construction of recombinant escherichia coli

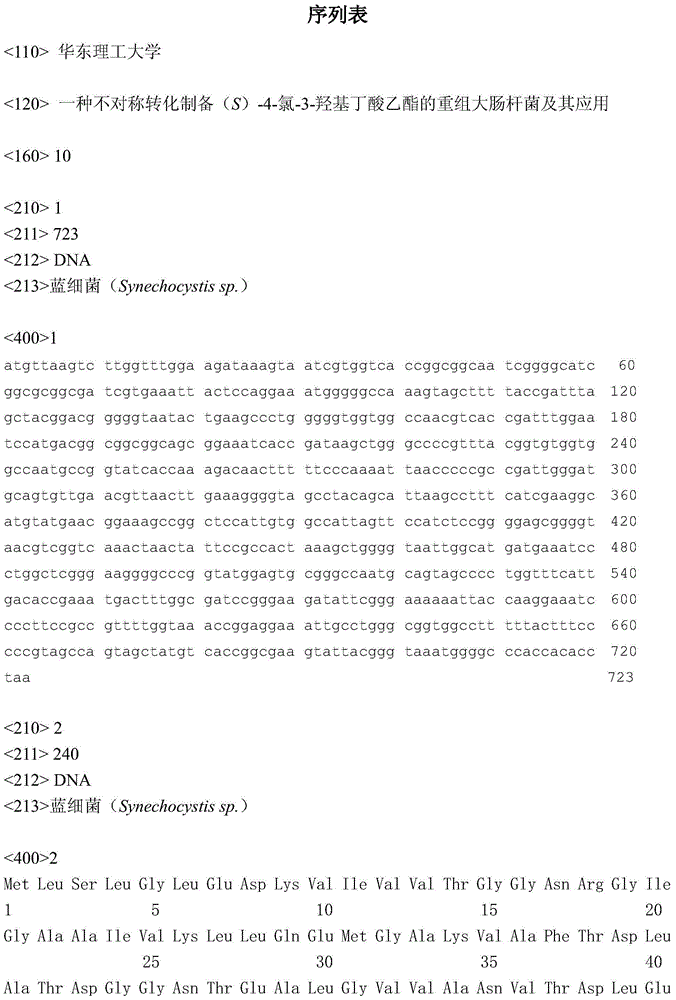

[0028] 1. Acquisition of carbonyl reductase gene:

[0029] Cyanobacteria Synechocystis sp.PCC 6803 (purchased from Pasteur Culture Collection of Cyanobacteria), medium Zobell 2216E (g L -1 ): peptone 5g, yeast extract 1g, ferric phosphate 0.1g, aged sea water 1000mL, pH 7.6.

[0030] The cyanobacteria Synechocystis sp.PCC 6803 was inoculated in 4 mL of Zobell 2216E liquid medium at 25°C to the logarithmic growth phase, and the genome was extracted using a genomic DNA extraction kit (Bacterial Genome Extraction Kit from Shanghai Jierui Company).

[0031] The primers used to construct the expression vectors are provided with enzyme cutting sites, and the primer sequences are as follows:

[0032]The upstream primer (SrCR-F contains Bam HI) is: AACGCGGATCCATGTTAAGTCTT GGTTTGGAAG, the downstream primer (SrCR-R contains HindⅢ) is: AACCCAAAGCTTAGGTGTGGTGGGCCCCATTT, and all primers are synthesized by Shanghai Jierui...

Embodiment 2

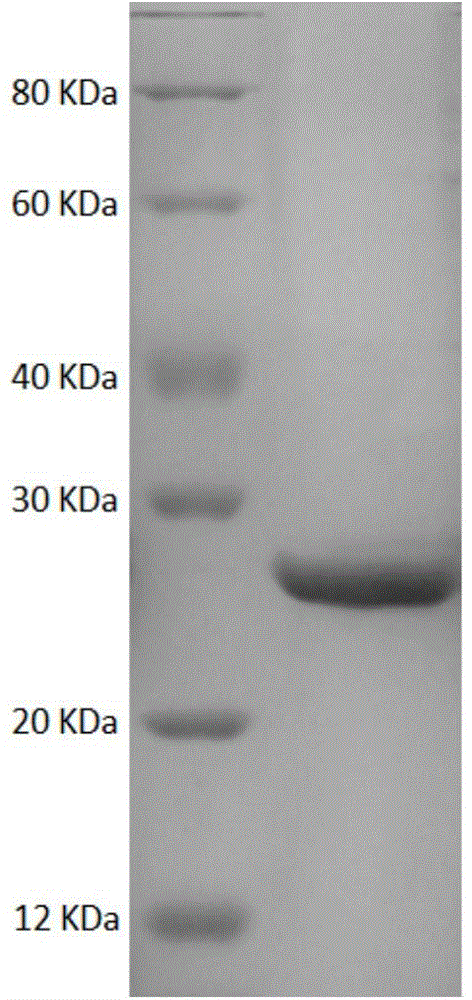

[0045] Example 2: Obtaining whole cells of recombinant Escherichia coli E.coli (pET28a-SrCR-GDH)

[0046] The transformants obtained in Example 1 were inoculated into LB liquid medium containing 50 μg / ml kanamycin resistance, cultured at 37° C. for 12 h, and then inoculated into fresh containing In 50ug / ml kanamycin-resistant LB liquid medium, culture at 37°C until the cell concentration OD600 is about 0.5, then add IPTG with a final concentration of 0.1mM to the LB liquid medium, and induce culture at 20°C for 20 hours, Centrifuge the culture solution at 4°C and 5000rpm for 6min, discard the supernatant, and collect the precipitate, which is the recombinant Escherichia coli (pET28a-SrCR-GDH) wet bacteria. Freeze-dried cells were obtained after the wet cells were freeze-dried for 4 hours. Centrifuge the precipitate after breaking the wet bacteria, take the supernatant and purify it with a nickel column, elute the impurity protein under 20mM imidazole, and elute the target pr...

Embodiment 3

[0047] Example 3: Application of the recombinant Escherichia coli in the preparation of (S)-CHBE

[0048] The freeze-dried thallus obtained in Example 2 was used as a catalyst. Weigh 0.5g freeze-dried bacteria and suspend in 25mL Trish-Hcl (100mM), add glucose 35mM, COBE 20mM, NADP 0.2mM, 30°C, react for 10min, the final substrate conversion rate reaches 100%, and the product optical purity e.e % is 99.4%.

[0049] The freeze-dried thallus obtained in Example 2 was used as a catalyst. Weigh 0.5g freeze-dried bacteria and suspend in 25mL Trish-Hcl (100mM), add glucose 600mM, COBE 400mM, NADP 0.2mM, 30℃, after 30min, the conversion rate of the final substrate reaches 100%, and the optical purity of the product is e.e. % is 99.3%.

[0050] The freeze-dried thallus obtained in Example 2 was used as a catalyst. Weigh 0.5g freeze-dried bacteria and suspend in 25mL Trish-Hcl (100mM), add glucose 900mM, COBE 600mM, NADP0.2mM, 30℃, after 1h reaction, the final substrate conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com