Cyclopentadiene-modified carbon nanotube/rubber composite material and preparation method thereof

A technology of cyclopentadiene and composite materials, applied in the field of nano-material modified rubber, which can solve the problems of reduced mechanical properties and limited applications of rubber products, and achieve the effects of strong interaction, excellent electrical conductivity and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

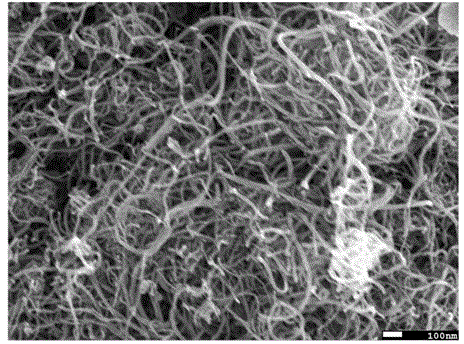

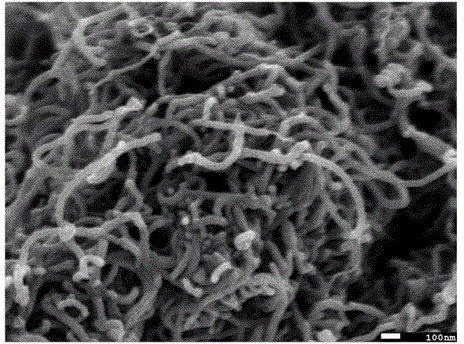

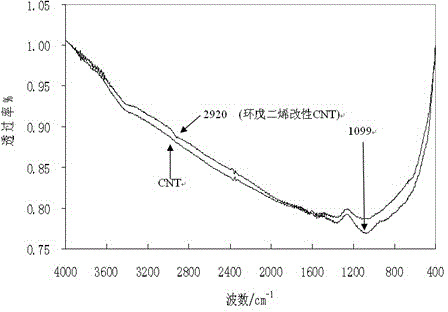

Image

Examples

Embodiment 1

[0040] Add 20 parts of multi-walled carbon nanotubes into a pressure-resistant glass reactor, add 20 parts of dicyclopentadiene, seal the reactor, heat the oil bath to 150°C for 20 hours, cool to room temperature after the reaction, and wash the reaction mixture with toluene Washing with methanol, filtering, and vacuum-drying the filter cake at 60° C. for 12 hours to obtain cyclopentadiene-modified carbon nanotubes with vinyl functional groups on the surface;

[0041] The above-mentioned cyclopentadiene modified carbon nanotubes were mixed with 100 parts of masticated natural rubber, 1 part of accelerator NS, 5 parts of zinc oxide, 2 parts of stearic acid, 1 part of anti-aging agent 4010NA, 0.5 part of N,N'-methylene Phenylbismaleimide, 5 parts of carbon black N330, 5 parts of calcium carbonate, 3 parts of environmentally friendly aromatic hydrocarbon oil, 0.5 part of zinc soap salt, mixed evenly in an internal mixer, degumming at 140°C, and adding open Cover the rollers in th...

Embodiment 2

[0048] 20 parts of multi-walled carbon nanotubes were weighed and added to a pressure-resistant glass reactor, and then 10 parts of dicyclopentadiene was added, the reactor was sealed, and the temperature was raised to 200° C. for 6 hours. After the reaction, cool to room temperature, wash the reaction mixture with toluene and methanol respectively, filter, and vacuum-dry the filter cake at 50° C. for 14 hours to obtain cyclopentadiene-modified carbon nanotubes with vinyl functional groups on the surface;

[0049] Add 5 parts of zinc oxide, 1 part of anti-aging agent 4010NA, 1 part of isocyanurate, 10 parts of carbon black N330 to the above-mentioned cyclopentadiene modified carbon nanotubes and 100 parts of EPDM rubber , 10 parts of calcium carbonate, 8 parts of naphthenic oil, and 0.5 parts of zinc soap salt were mixed evenly, degummed at 140 ° C, cooled, added to the open mill to cover the rolls, added 3 parts of dicumyl peroxide, mixed evenly, and then After standing for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com