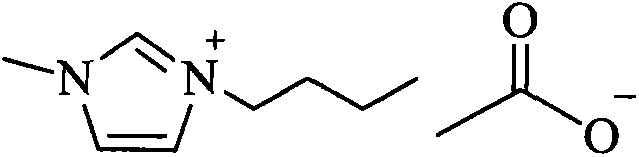

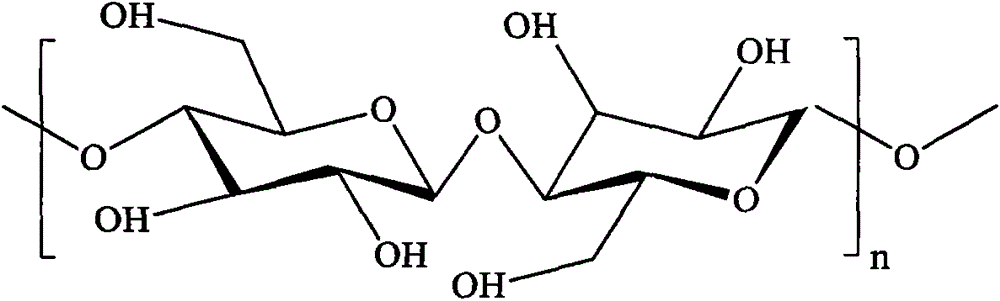

Method used for fractional separation of cellulose with different polymerization degrees using ionic liquid-carbon dioxide system

A technology of ionic liquid and carbon dioxide, which is applied in the production of bulk chemicals, can solve the problems of changing the solvation properties of solvents and affecting the effect of solvent resistance, and achieves the effect of simple method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]At 120°C, the microcrystalline cellulose was dissolved in the ionic liquid [Bmim]OAc, the mass ratio of the microcrystalline cellulose to the ionic liquid [Bmim]OAc was 10:100, and the ionic liquid solution of the microcrystalline cellulose was obtained, and an appropriate amount of This solution is put into a high-pressure reactor, and the device is placed in a constant temperature water tank. At 25°C, a pressure of 7 MPa is introduced to compress carbon dioxide to a system pressure of 6.60 MPa. After standing for 3 hours, the pressure is slowly reduced to 0.004 MPa, and the resulting At the same time, the ionic liquid [Bmim]OAc can also be recovered; the collected gas is passed into clarified lime water, so that the solution becomes turbid first and then becomes clear. It can be seen that its main component is carbon dioxide, and the anti-solvent carbon dioxide is completed. collect.

[0037] Combining Magic Angle Rotation Technique with Fourier Transform Infrared Spec...

Embodiment 2-8

[0040] According to the method of Example 1, only the pressure of 7MPa compressed carbon dioxide to the pressure of the system is passed through at 25°C. The strength is 6.60MPa" and replaced by:

[0041] "At 25°C, a pressure of 9 MPa is introduced to compress carbon dioxide to a system pressure of 8.00 MPa",

[0042] "At 25°C, a pressure of 11MPa is introduced to compress carbon dioxide to a system pressure of 10.00MPa",

[0043] "At 25°C, a pressure of 13MPa is introduced to compress carbon dioxide to a system pressure of 12.00MPa",

[0044] "At 25°C, a pressure of 15MPa is introduced to compress carbon dioxide to a system pressure of 14.00MPa",

[0045] "At 25°C, a pressure of 17MPa is introduced to compress carbon dioxide to a system pressure of 16.00MPa",

[0046] "At 25°C, a pressure of 19MPa is introduced to compress carbon dioxide to a system pressure of 18.00MPa",

[0047] "At 25°C, a pressure of 21MPa is introduced to compress carbon dioxide to a system pressure...

Embodiment 9-12

[0052] According to the method of Example 1, only "at 25°C, pressurize carbon dioxide at a pressure of 7 MPa to compress the carbon dioxide to a system pressure of 6.60 MPa, and let it stand for 3 hours" are replaced by

[0053] "At 25°C, inject pressure of 7MPa to compress carbon dioxide to a system pressure of 6.60MPa, and let it stand for 1h",

[0054] "At 25°C, inject pressure of 7MPa to compress carbon dioxide to a system pressure of 6.60MPa, and let it stand for 2h",

[0055] "At 25°C, inject pressure of 7MPa to compress carbon dioxide to a system pressure of 6.60MPa, and let it stand for 5h",

[0056] "At 25°C, a pressure of 7 MPa is introduced to compress carbon dioxide to a system pressure of 6.60 MPa, and it is left to stand for 10 hours",

[0057] The yields of the obtained regenerated cellulose were 17.1%, 34.5%, 59.0%, and 59.2%, respectively.

[0058] The viscosity-average molecular weight of regenerated cellulose was obtained by Ubbelohde viscometer method, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com