Metal complex, preparation method and use thereof, display device

A technology for metal complexes and display devices, which is applied in electric solid devices, semiconductor devices, ruthenium organic compounds, etc., can solve the problem of low luminous efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

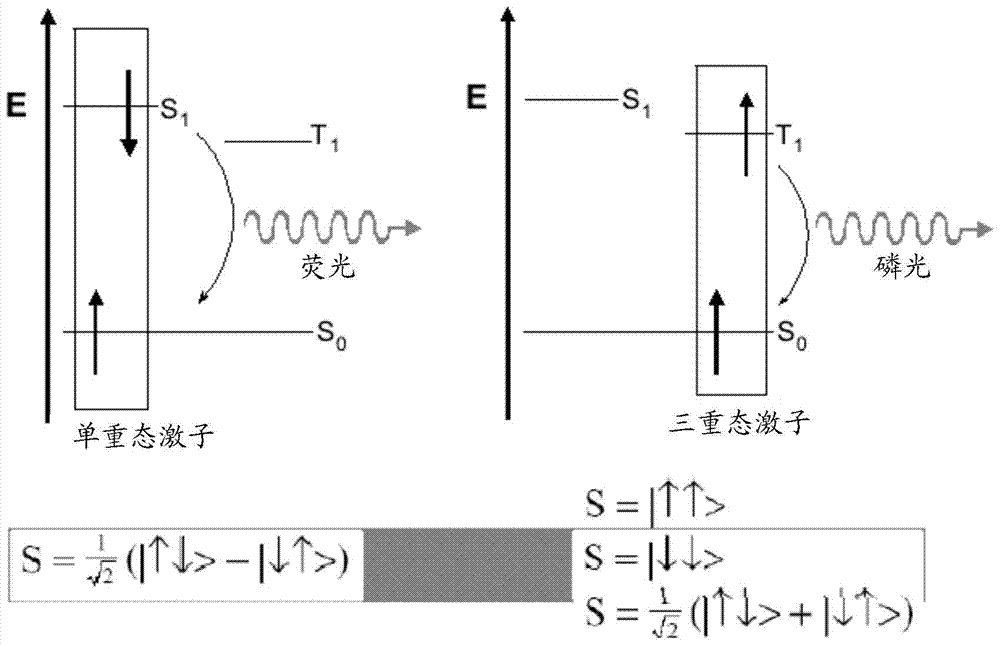

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

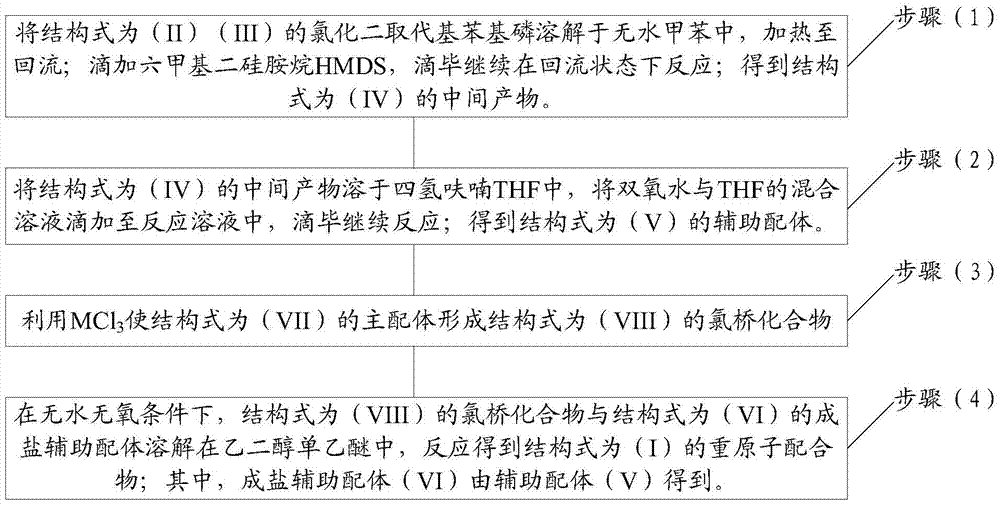

[0075] Corresponding to the above-mentioned metal complexes, an embodiment of the present invention also provides a preparation method of the metal complexes, such as figure 2 As shown, the preparation method mainly includes the following four steps, and it should be noted that the order of steps (1) to (2) and step (3) can be changed.

[0076] Step (1): dissolving the chlorinated disubstituent phenylphosphorus with structural formula (II)(III) in anhydrous toluene, heating to reflux, wherein, the R 1 , R 2 , R 3 or R 4 F, CF independently 3 、CH 3 , or substituted phenyl; drip hexamethyldisilazane HMDS, and dropwise continue to react under reflux state; obtain the intermediate product of structural formula (IV);

[0077]

[0078] Optionally, in this step, the molar ratio of disubstituted phenylphosphine chloride with structural formula (II)(III) to hexamethyldisilazane HMDS is 1:1:(0.8˜1.2).

[0079] Optionally, after adding the HMDS dropwise, the reflux time is 5-7 ...

Embodiment 1

[0097] Embodiment 1 green light Ir complex

[0098]

[0099] Its synthetic steps can be shown by a series of reaction formulas below.

[0100]

[0101] (1) Synthesis of auxiliary ligands and their potassium salts

[0102] Under anhydrous and oxygen-free conditions, dissolve 20mmol of disubstituted phenyl phosphorus chloride in 30mL of anhydrous toluene, heat to reflux, slowly add 11mmol of hexamethyldisilamine (HMDS) dropwise, and continue to The reaction was carried out under reflux for 6 hours. After the reaction was completed, it was cooled, and the reaction by-products trimethylchlorosilane and toluene were removed by rotary evaporation.

[0103] Then the product was dissolved in 4mL THF, and the mixed solution of 2mL 30% hydrogen peroxide and 10mL THF was slowly added dropwise to the reaction liquid, and reacted for 2 hours after the dripping, and poured the liquid into 100mL diethyl ether solution after the end, and there was a large amount of white precipitate F...

Embodiment 2

[0120] Embodiment 2 red light Ir complex

[0121]

[0122] Its synthetic steps can be shown by a series of reaction formulas below.

[0123]

[0124] (1) Synthesis of auxiliary ligands and their potassium salts

[0125] The synthesis steps of the auxiliary ligand and its potassium salt are the same as those in Example 1.

[0126] (2) Synthesis of metal complexes

[0127] The synthesis steps of the metal complex are the same as those in Example 1.

[0128] Yield: 23%

[0129] Characterization of chemical properties:

[0130] 1 H NMR (500MHz, CDCl 3, ppm) δ8.97(d,J=6.3Hz,2H),8.46–8.36(m,2H),7.79–7.62(m,12H),7.40–7.30(m,6H),7.19–7.09(m,4H ),7.04(d,J=6.3Hz,2H),6.45–6.38(m,2H),5.78–5.71(m,2H).MADI-TOF,m / z:[M]calcd for C 78 h 32 f 24 IrN 3 o 2 P 2 ,1753[M]; found 1754.7[M+1]. Melting point: >310℃.

[0131] Elemental analysis results: calculated value: C (%): 53.43 H (%): 1.84 N (%): 2.40

[0132] Measured value: C(%): 53.38 H(%): 1.82 N(%): 2.44

[0133] attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com