High polymer bonded explosive with nanoparticle enhanced mechanical properties and preparation method thereof

A technology of nanoparticles and high polymers, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive composition, nitroalkane composition, aromatic nitration composition, etc., can solve the problems of mechanical property degradation and achieve High energy density, improved mechanical properties, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

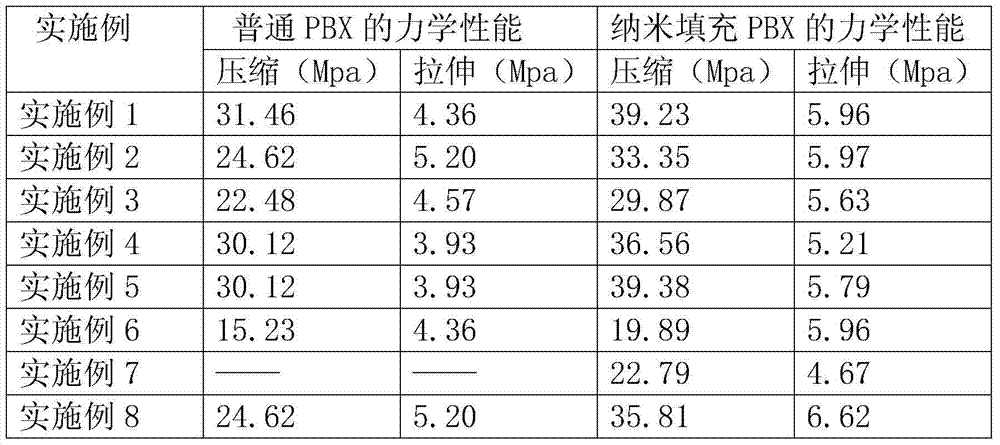

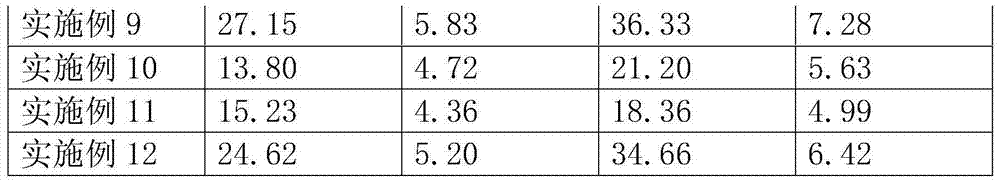

Embodiment 1

[0023] Weigh 10.0g of TATB with a particle size of 20-30μm, weigh 10.0g of nano-TATB with a particle size of 100nm, mix and add to the reaction kettle, add 5.0ml of distilled water, stir at 50°C for 20min; raise the temperature to 70°C, drop Add the ethyl acetate-butyl acetate solution of F2314 with a solute mass fraction of 4%, the mass ratio of the ethyl acetate-butyl acetate solution of F2314 to the explosive particle raw material is 1:1, and the dropping rate is 6.0 at the beginning of the dropping ml / min, add dropwise until a large number of small explosive particles appear, reduce the dropping rate to 2.0ml / min, lower the temperature to 20°C after the binder is completely added dropwise, stop stirring, wash with distilled water twice, and place in an oven at 55 The explosive composite particles were obtained by drying at ℃; finally, 6.0 g of explosive composite particles were weighed and pressed into powder columns, and the mechanical properties were tested, as shown in T...

Embodiment 2

[0025] Weigh 10.0g of HMX with a particle size of 10-50μm, weigh 6.0g of nano-HMX with a particle size of 600nm, mix and add to the reaction kettle, add 3.0ml of distilled water, stir at 55°C for 30min; raise the temperature to 60°C, drop Add the ethyl acetate-butyl acetate solution of F2311 with a solute mass fraction of 4%, the mass ratio of the ethyl acetate-butyl acetate solution of F2311 to the explosive particle raw material is 1:1, and the initial dropping rate is 7.0ml / Min, add dropwise until a large amount of small explosive particles appear, reduce the drop rate to 3.0ml / min, after the dropwise addition, lower the temperature to 20°C, stop stirring, wash with distilled water for 3 times, then dry in an oven at 50°C to obtain explosive composite particles ; Finally, 4.0g of explosive composite particles were weighed and pressed into powder columns, and the mechanical properties were tested, as shown in Table 1.

Embodiment 3

[0027] Weigh 8.0g of HNS with a particle size of 5-30μm, weigh 3.0g of nano-HNS with a particle size of 400nm, mix and add to the reaction kettle, add 6.0ml of distilled water, stir at 50°C for 30min; raise the temperature to 60°C, drop Add the ethyl acetate-butyl acetate solution of F2311 with a solute mass fraction of 4%, the mass ratio of the ethyl acetate-butyl acetate solution of F2311 to the explosive particle raw material is 1:1, and the initial dropping rate is 7.0ml / min. Add dropwise until a large number of small explosive particles appear, reduce the dropping rate to 3.0ml / min, lower the temperature to 20°C after the dropwise addition, stop stirring, wash with distilled water for 3 times, and dry in an oven at 50°C to obtain explosive composite particles; finally Weigh 5.5g of explosive composite particles and press them into powder columns, and test the mechanical properties, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com