Nano-scale manganese monoxide-conductive carbon black composite material and synthetic method thereof

A technology of conductive carbon black and manganese oxide, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limiting electrochemical performance, achieve environmental friendliness, simple technical process, excellent The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of manganese oxide / conductive carbon black composite material and electrochemical performance test of a simulated battery assembled with Li.

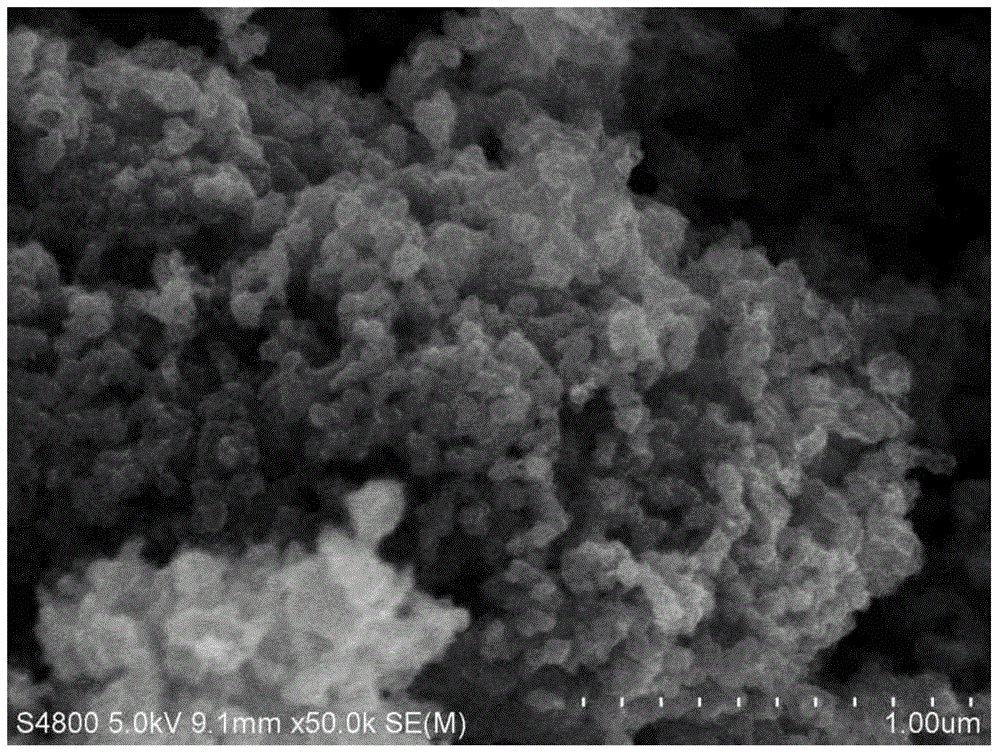

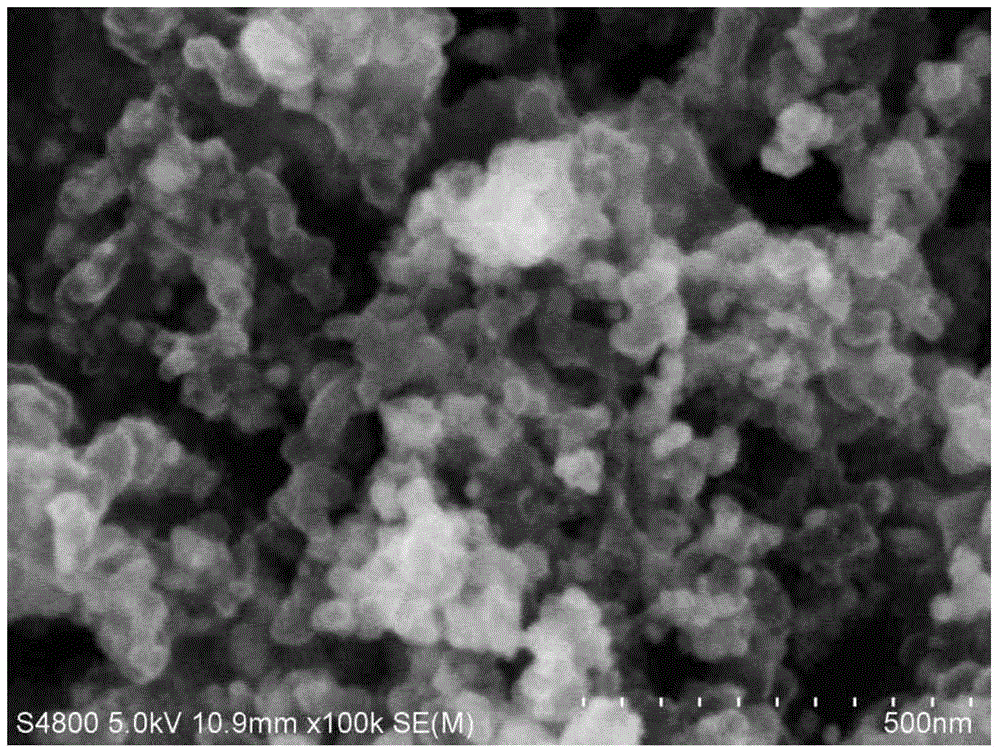

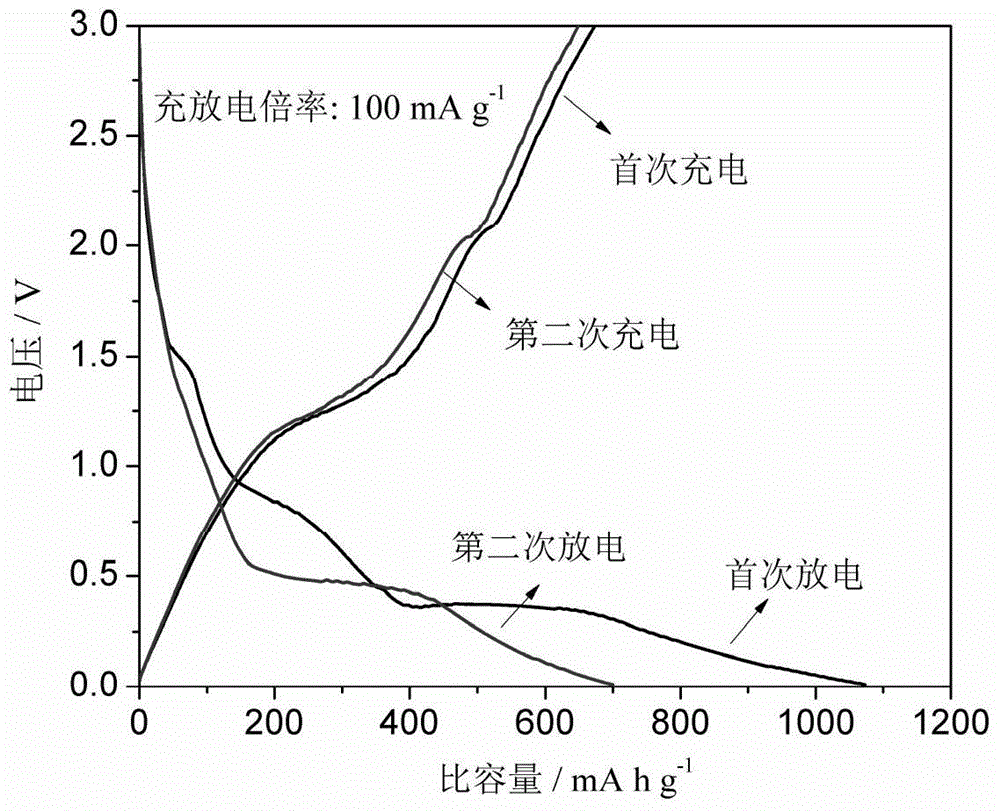

[0028] Dissolve 2 g of potassium permanganate (purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd.) in 500 mL of deionized water, add 1 g of conductive carbon black (purchased from Shanghai Heshibi Co., Ltd.), and mix thoroughly and evenly. The resulting mixture was reacted at 60°C for 12 hours, filtered, the product was fully washed with deionized water, and dried. The microscopic appearance of the obtained manganese oxide / conductive carbon black composite was as follows: figure 1 . In a tube furnace in a mixture of hydrogen and argon (10% H 2 , 90% Ar) at a rate of 1°C / min to 400°C, keep the temperature for 5h, and cool down to room temperature naturally to obtain a nano-manganous oxide / conductive carbon black composite material with a microstructure such as figure 2 As shown, the particle size...

Embodiment 2

[0030] Example 2: Preparation of manganese oxide / conductive carbon black composite material and electrochemical performance test of a simulated battery assembled with Li.

[0031] Dissolve 4 g of potassium permanganate (purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd.) in 500 mL of deionized water, add 1 g of conductive carbon black (purchased from Shanghai Hersbit Company), and mix thoroughly and evenly. The resulting mixture was reacted at 60°C for 16 hours, filtered, the product was fully washed with deionized water, and dried. In a tube furnace in a hydrogen-nitrogen mixed atmosphere (10% H 2 , 90%N 2 ) at a rate of 2°C / min to 500°C, heat preservation for 2h, and naturally cool to room temperature to obtain nano-manganese oxide / conductive carbon black composite material; the particle size of the obtained manganese oxide / conductive carbon black composite is 50nm-80nm. The material is prepared as the negative electrode of lithium-ion battery, and the charge-dis...

Embodiment 3

[0032] Example 3: Preparation of manganous oxide / conductive carbon black composite material and electrochemical performance test of a simulated battery assembled with Li.

[0033] 1 g of potassium permanganate (purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd.) was dissolved in 499 mL of deionized water, and 1 g of conductive carbon black (purchased from Shanghai Heshibi Co., Ltd.) was added, fully mixed and evenly stirred. The resulting mixture was reacted at 80°C for 6 hours, filtered, the product was fully washed with deionized water, and dried. In a tube furnace in an argon atmosphere, the temperature was raised to 700°C at a rate of 5°C / min, kept for 2 hours, and naturally cooled to room temperature to obtain nano-manganese oxide / conductive carbon black composite materials, manganese oxide / conductive carbon black composite materials The particle size of the substance is 50nm-80nm; its XRD diffraction image is as follows Figure 8As shown, it has a good correspo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com