Force Sensors Using Integral Force Biasing for Improved Linearity

A force sensor and sensor technology, applied in the field of force sensors with a linear correction method, can solve problems such as collision with external objects, and achieve the effects of improved accuracy, improved medical treatment, and improved measurement repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

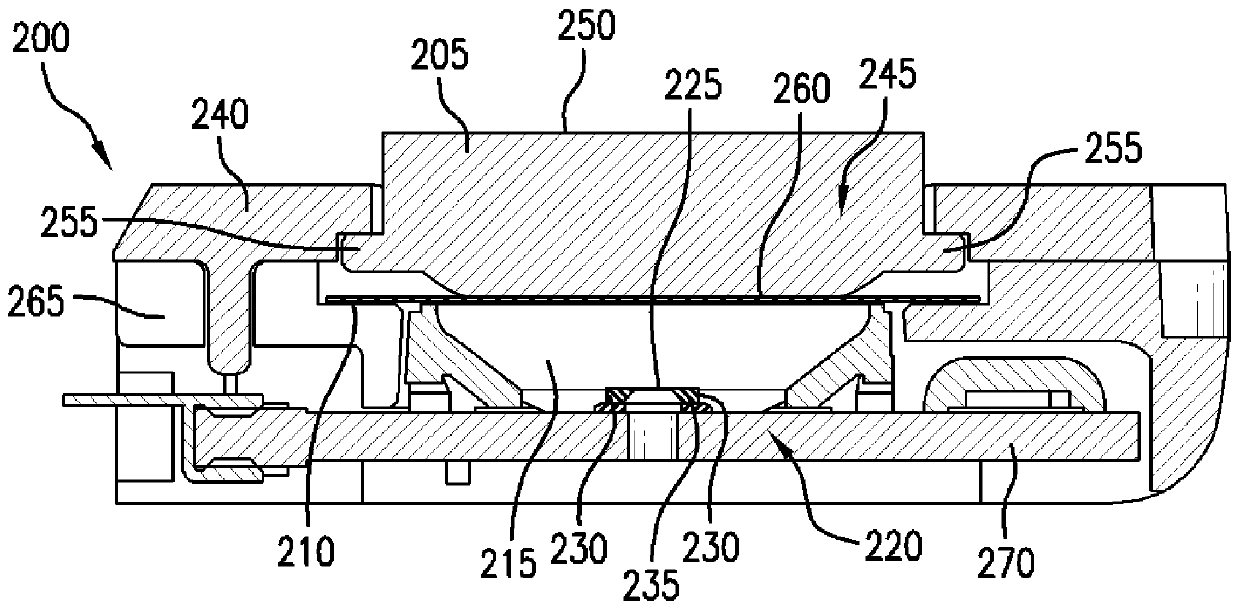

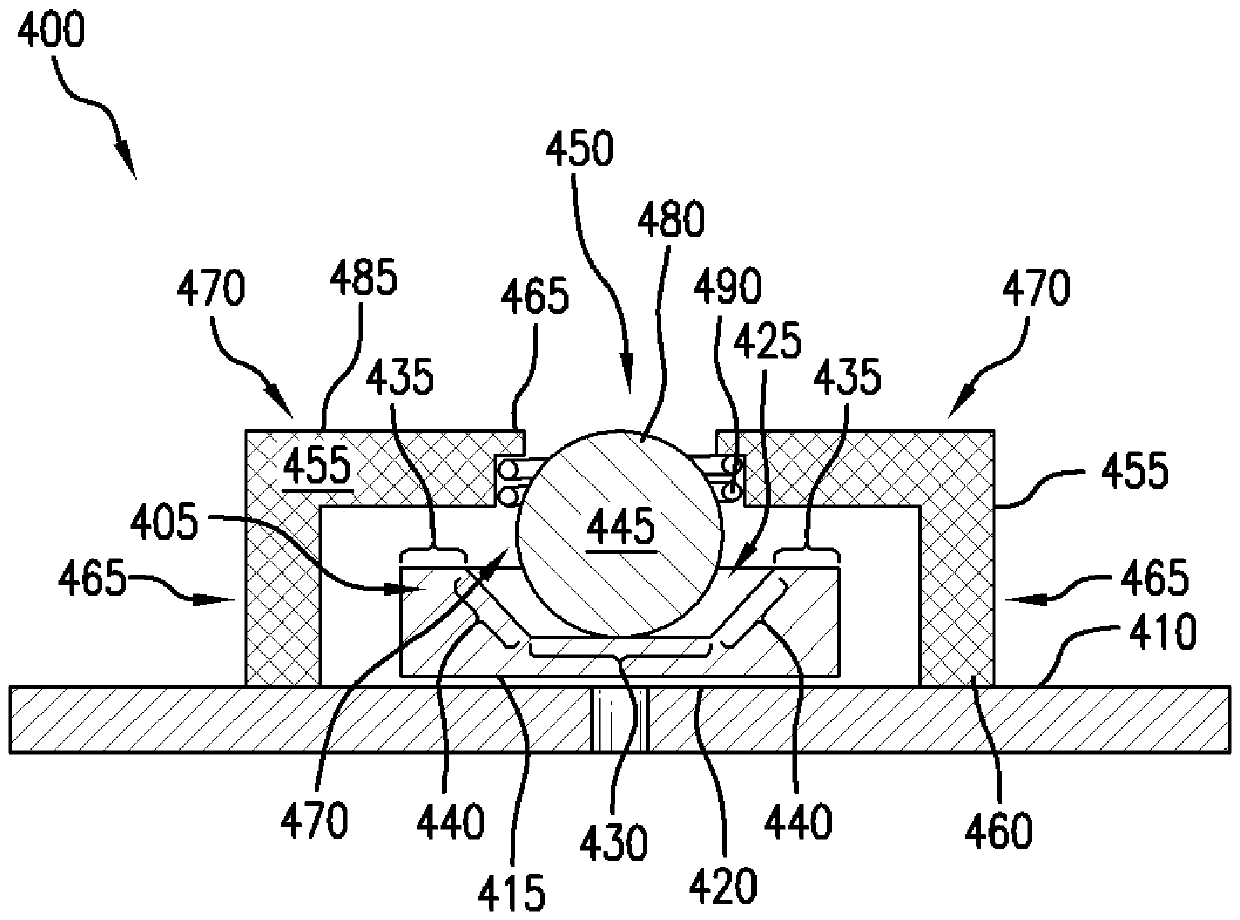

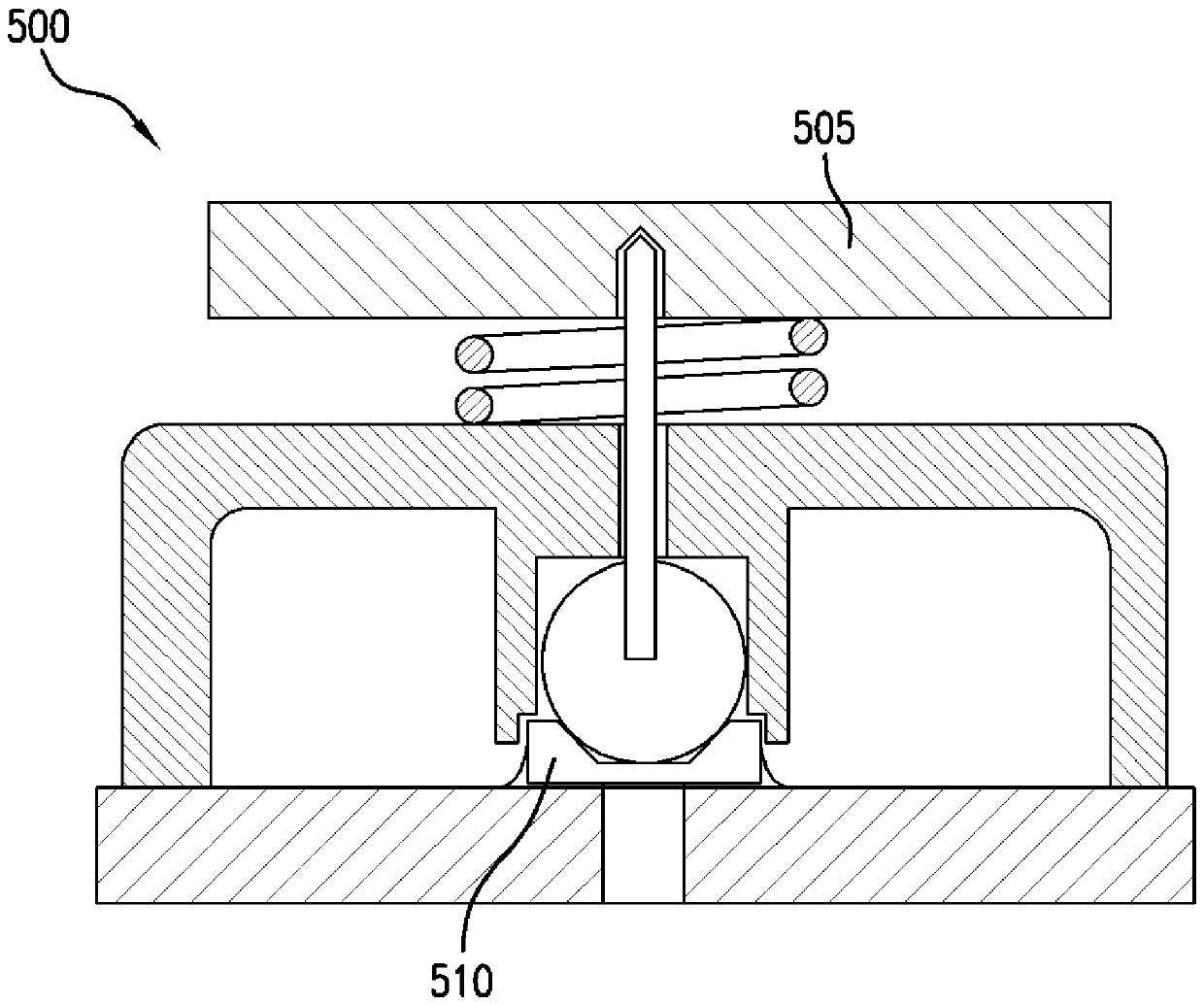

[0023] To aid understanding, this document is organized as follows. First, refer to Figure 1A - 1C, An exemplary application of a force sensor used in a medical environment is briefly described to introduce some advantages of a force biased force sensor. Second, refer to Figure 2-3 , an exemplary preloaded force sensor having a force transmission device including a colloid transmission member will be described. Next, refer to Figure 4-5 , the discussion turns to an exemplary force bias using a mechanical force transfer member. Finally, refer to Figure 6-7 , an exemplary performance improvement will be discussed using a response graph and an error graph showing non-preloaded measurements. The improvement in performance due to preloading the sensors used to obtain these measurements will be described from these figures.

[0024] Figures 1A-1B An exemplary scenario is shown in which a force sensor is used to monitor the flow of drug into a patient. exist Figure 1A I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com