Assembling type frame structure

A frame structure and prefabricated technology, applied to building components, building structures, floor slabs, etc., can solve the problems of poor structural integrity and redundancy, poor quality and production efficiency of prefabricated components, and transportation difficulties, etc. problem, to achieve the effect of reducing workload, facilitating large-scale production, and ensuring structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

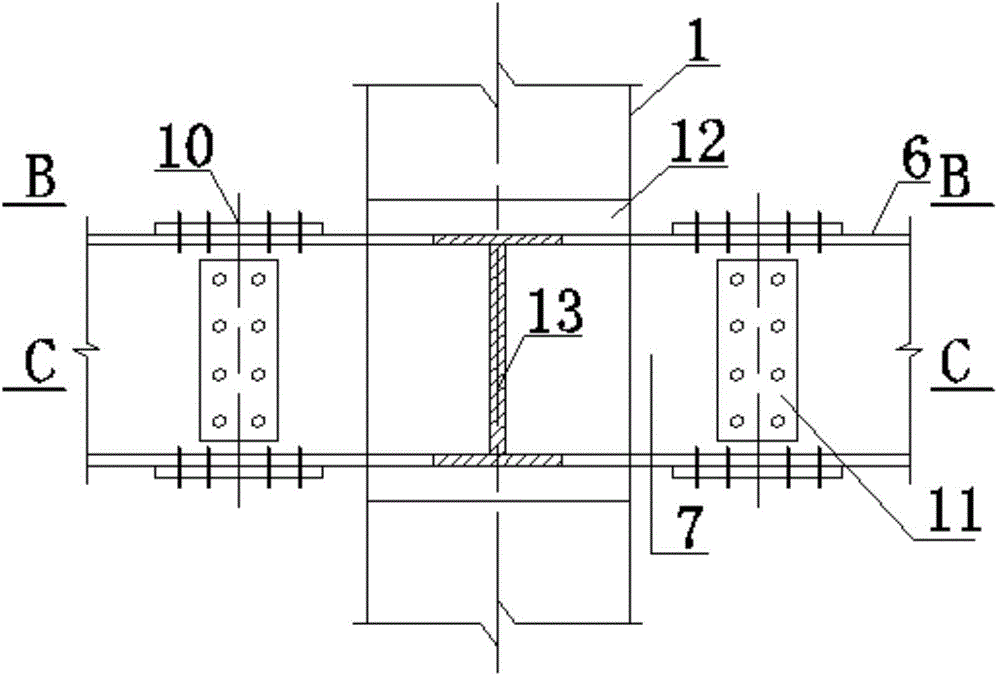

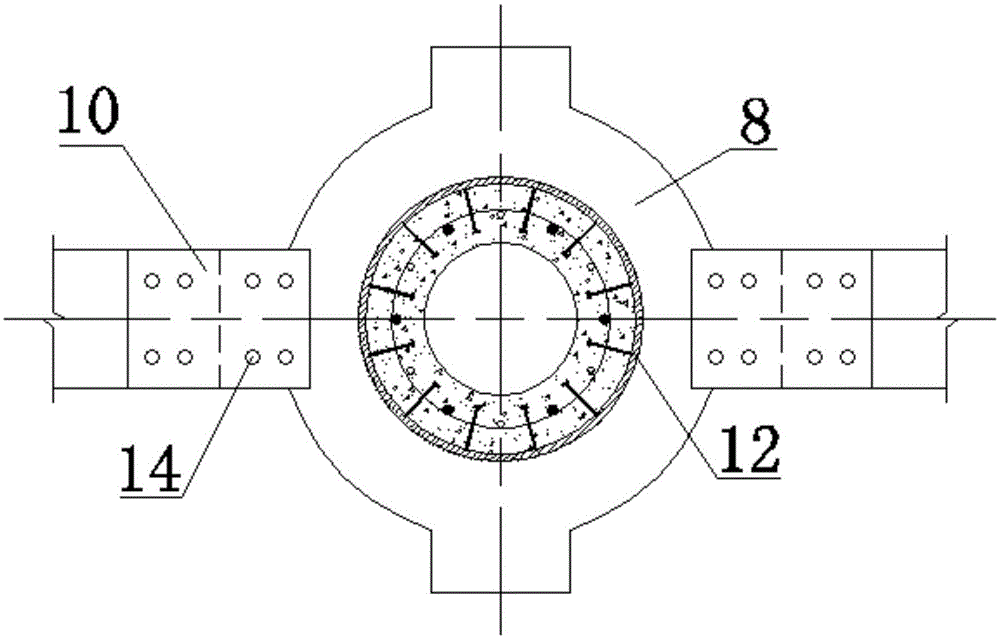

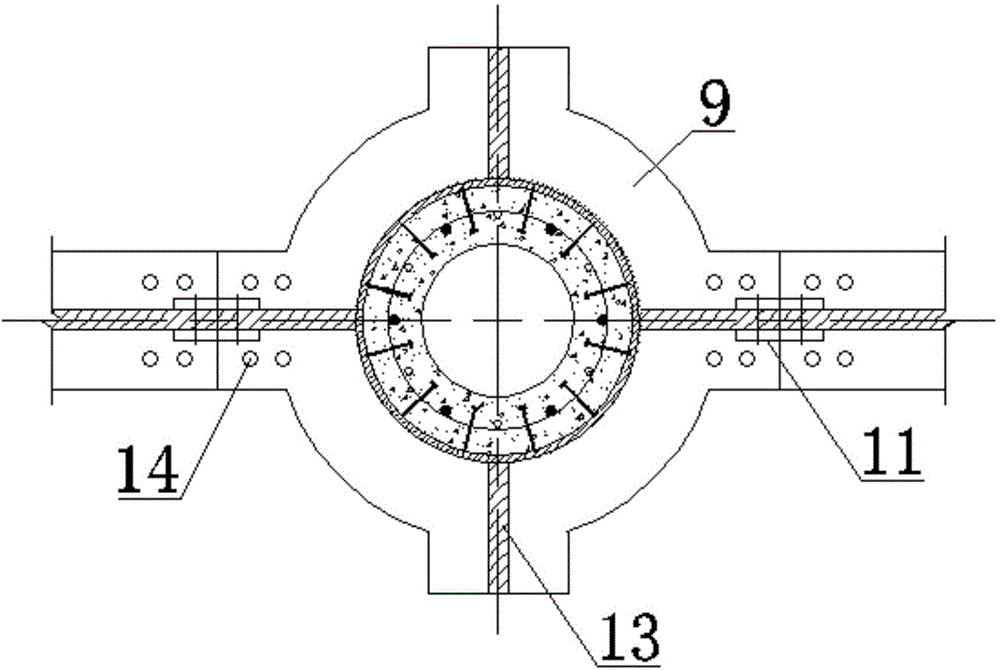

[0021] see Figure 1 to Figure 7 , an assembled frame structure, including a pipe column 1 and a steel beam 6, the pipe column 1 and the steel beam 6 are connected by a node 7, the pipe column 1 and the steel beam 6 are prefabricated parts, the The pipe column 1 is made by the pre-tensioned prestressed centrifugal forming process, and the height of each pipe column 1 is three or four storeys high, so as to reduce the number of assembly nodes of the frame column.

[0022] The above-mentioned column 1 may be a corner column, a side column or a central column of a frame structure.

[0023] In this embodiment, two vertically adjacent pipe strings 1 are connected by flanges. A pre-embedded steel pipe 12 forming the node is arranged on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com