Interlayer color sprayed anti-counterfeit coating white cardboard and production process thereof

A white cardboard and coating technology, which is applied in coating, paper, papermaking, etc., can solve the problems affecting the application of anti-counterfeiting packaging, achieve the effect of simple and easy identification, increase the cost of imitation, and facilitate post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

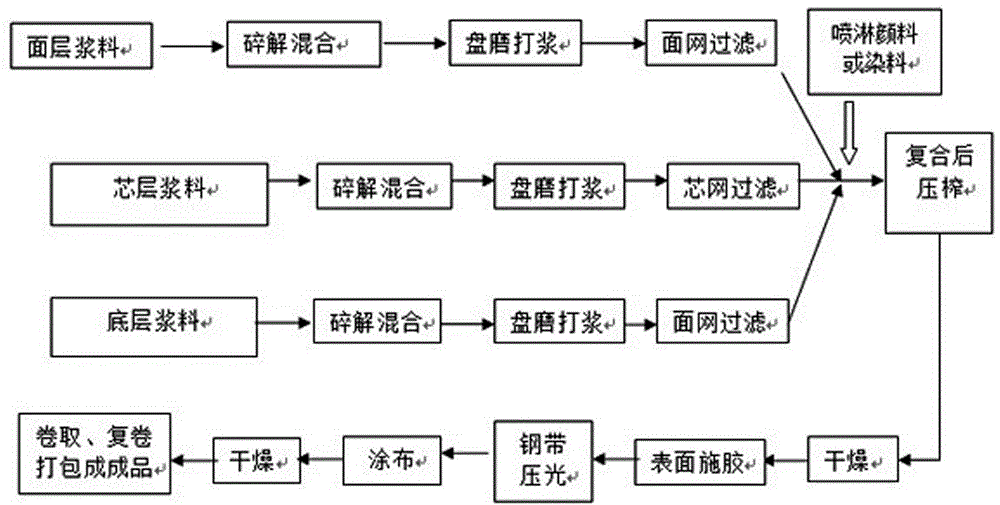

[0023] Such as figure 1 In the steps shown, the surface layer slurry (percentage by weight: 70% of bleached hardwood kraft pulp, 30% of bleached softwood kraft pulp), the core layer slurry (percentage by weight: 50% of bleached hardwood kraft pulp, Bleached softwood kraft pulp 10%, broken paper 40%) and bottom pulp (weight percentage: bleached hardwood kraft pulp 90%, bleached softwood kraft pulp 10%) are crushed, mixed and screened by pulper , Disc Refiner Refining, Blending, Sending to Paper Machine for Papermaking and Water Filtration; Surface Layer Slurry, Core Layer Slurry, and Bottom Layer Slurry are Compounded, and when the Surface Core Layer and Core Bottom Layer are compounded, press 10g spray lithopone per ton of paper; pressed to produce wet paper with surface layer, core layer and bottom layer, the wet paper is dried, surface sizing, steel belt calendered to obtain base paper, and then coated : Coating a pre-coat on the surface layer, coating a core coating on the...

Embodiment 2

[0026] The surface layer slurry (percentage by weight: bleached hardwood kraft pulp 90%, bleached softwood kraft pulp 10%), core layer slurry (weight percent: bleached hardwood kraft pulp 55%, bleached softwood kraft pulp Pulp 20%, broken paper 25%) and bottom pulp (weight percentage: bleached hardwood kraft pulp 70%, bleached softwood kraft pulp 30%) are crushed and mixed by pulper, screened, and disc refined Refining, blending, sending to the paper machine for papermaking and water filtration; composite the surface layer slurry, core layer slurry, and bottom layer slurry, and spray 150g of paper per ton between the surface and core layers when the surface and core layers are compounded Lead chrome yellow; wet paper with surface layer, core layer and bottom layer is produced by pressing, the wet paper industry is dried, surface sizing, and steel belt calendered to obtain base paper, and then coated: coating on the surface layer Cloth pre-coating, coating the core coating on t...

Embodiment 3

[0029] The surface layer pulp (weight percentage: bleached hardwood kraft pulp 80%, bleached softwood kraft pulp 20%), core layer pulp (weight percentage: bleached chemical thermomechanical pulp 55%, bleached softwood kraft pulp Pulp 5%, broken paper 40%) and bottom pulp (weight percentage: bleached hardwood kraft pulp 80%, bleached softwood kraft pulp 20%) are crushed, mixed, screened, and disc-refined by pulper Machine refining, mixing, sending to paper machine for papermaking and water filtration; compounding of surface layer slurry, core layer slurry and bottom layer slurry, and spraying toluidine at a rate of 100g per ton of paper between the core and bottom layers when compounding the core and bottom layers Red; press to produce wet paper with surface layer, core layer and bottom layer, the wet paper industry is dried, surface sizing, and steel belt calendered to obtain base paper, and then coated: coating pre-coated on the surface layer Coating, coating the core coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com