Pyrolysis device for carbonaceous substance

A pyrolysis and material technology, applied in the removal of gas pollutants, catalytic conversion of impurities, gas purification, biofuels, etc., can solve the problems of easy deactivation of catalysts, high tar dust content, and difficulty in stable operation, etc., to achieve simplification Effects of pyrolysis process flow, improved separation efficiency, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

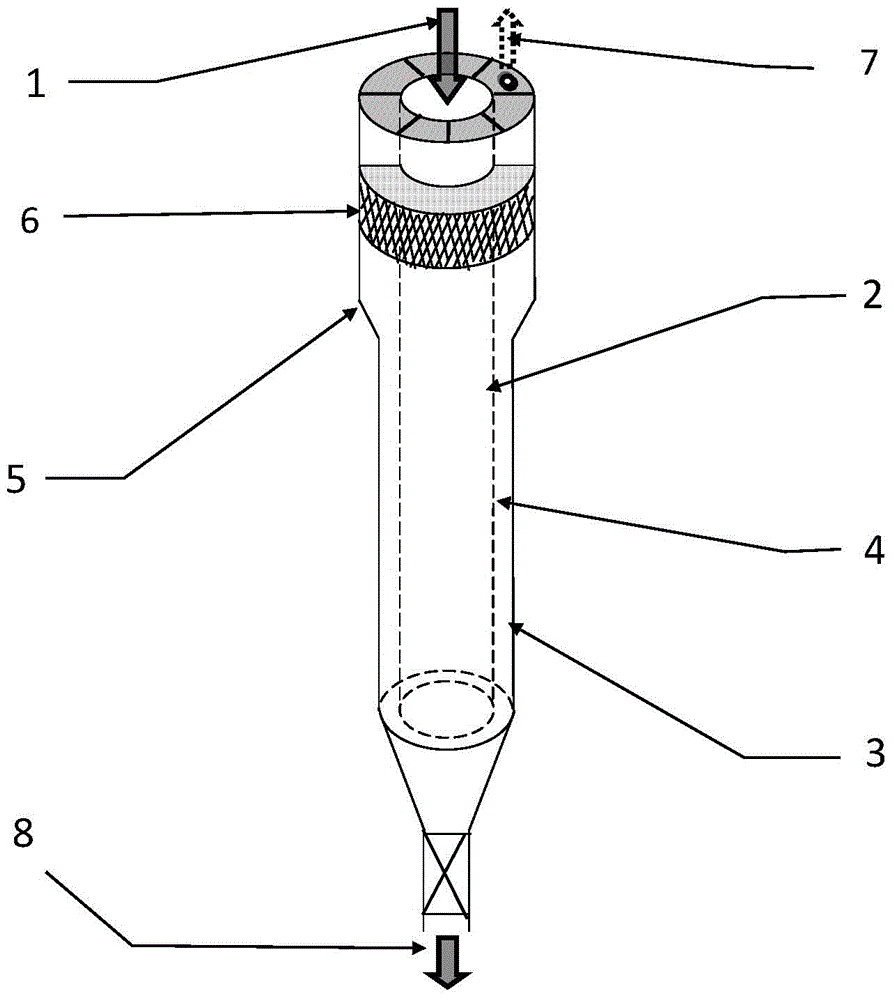

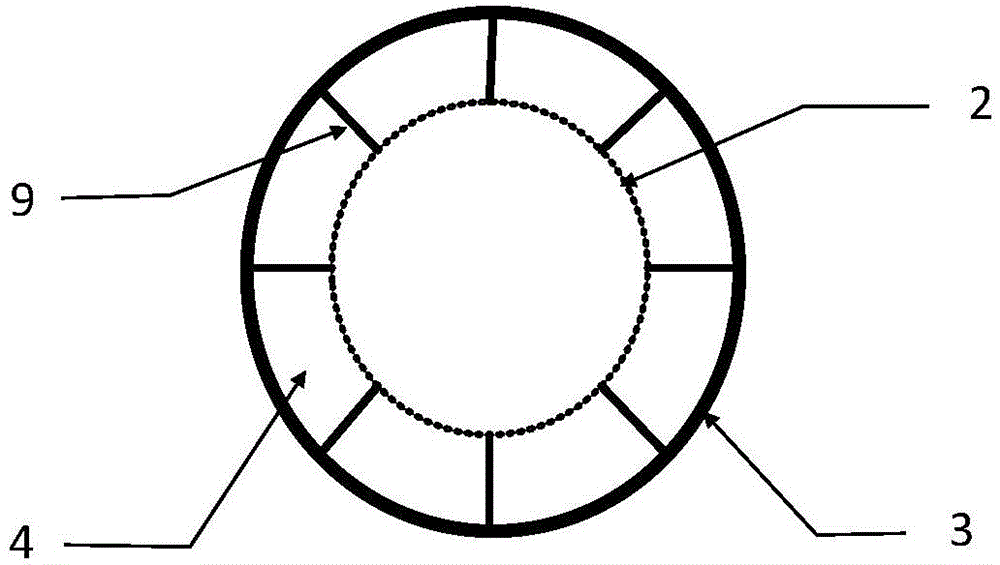

[0035] Pulverized coal with a particle size of 200 meshes, after drying at 105 °C, is added to the inner tube 2 of the pyrolyzer from the top feed port 1 of the pyrolyzer. In the range of ℃, the pulverized coal undergoes a pyrolysis reaction, and the gaseous products are led out through the inner tube with an average filter diameter of 0.5 mm) into the gas collection chamber 4 between the double casings. The high-temperature pyrolysis gas flows upward in the gas collection chamber, and passes through the The diameter-expanding section 5 and the filter layer 6 of the outer tube are discharged from the gas-phase product overflow port 7, and the pyrolysis gas and the pyrolysis oil are separated after the cooling treatment; The coke removal operation is performed at the bottom of the decoking device, so that the semi-coke is released from the coke removal port 8, and the coke quenching treatment is performed. The pyrolysis oil and gas treatment and collection technology and coke q...

Embodiment 2

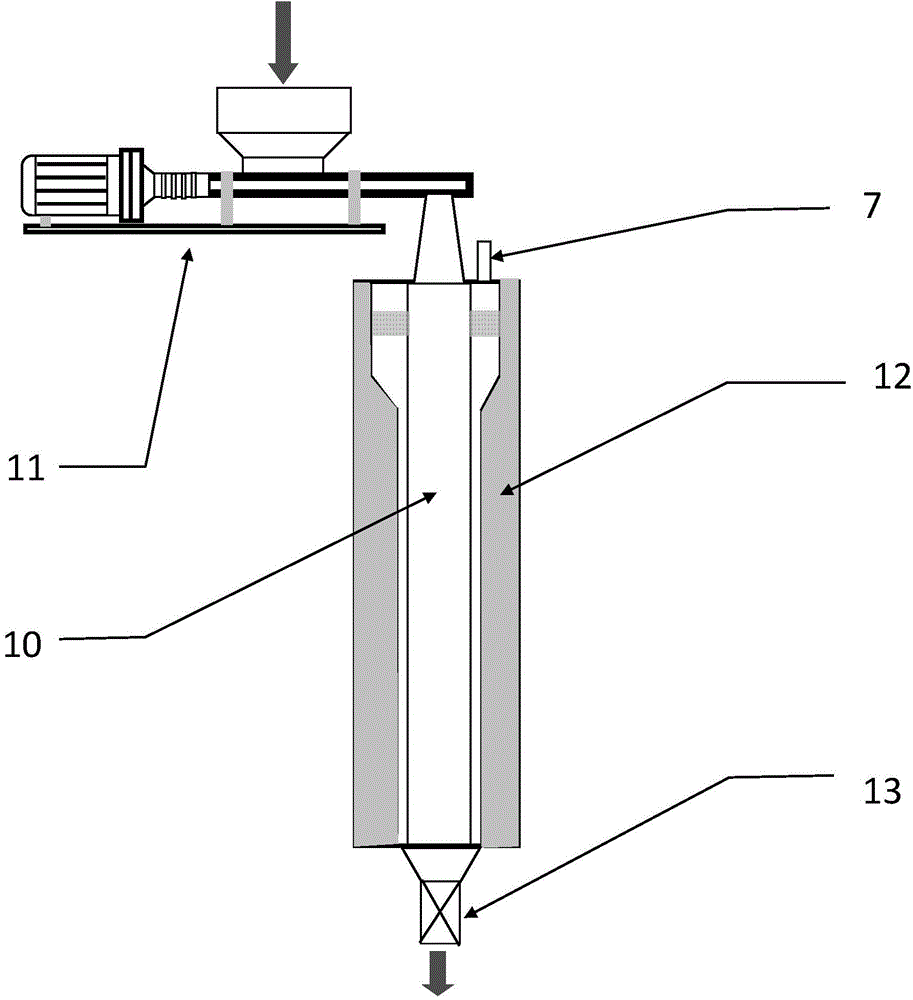

[0038] Pulverized coal with a particle size of less than 1mm, after drying at 105°C, adopts the mode of internal heating and pyrolysis, and mixes with quartz sand with an average particle size of 2.5mm at 950°C at the top inlet 1 of the pyrolyzer, and adds In the inner tube 2 of the pyrolyzer, quartz sand is used as the heat carrier to heat the pulverized coal particles. pyrolysis reaction. The generated high-temperature pyrolysis gas is filtered by the inner tube (filter diameter ~ 0.45mm), and enters the gas collection chamber 4 between the double casings. 5 and the filter layer 6 are discharged at the gas-phase product overflow port 7, and the pyrolysis gas and the pyrolysis oil are separated through a cooling treatment. Coke quenching, pyrolysis gas treatment and collection technology related to pyrolysis, as well as quartz sand and pyrolysis semi-coke separation and heat carrier circulation technology can be processed in the existing mature way.

Embodiment 3

[0040] The mixed waste biomass of pine wood chips, sawdust and rice husks dried at 105°C is crushed by a high-speed pulverizer and added from the feed inlet at the top of the pyrolyzer. In the external heating mode, the temperature of the inner tube of the pyrolyzer is increased When the temperature is kept in the range of 400-750°C, the biomass undergoes a pyrolysis reaction, and the pyrolysis high-temperature gaseous products are exported through the filtration of the inner tube (the filter diameter is between 0.1-0.5mm), and enter the gas collection chamber 4 between the double casings , the high-temperature pyrolysis gas flows upward in the gas collection chamber, passes through the diameter expansion section 5 and the filter layer 6 of the outer tube, and is discharged at the gas-phase product overflow port 7, and separates the pyrolysis gas and the pyrolysis oil through cooling treatment; After the oil shale powder in the inner wall of the disintegrator reaches the predet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com