Low-molecular hyperbranched oil-soluble thickened oil viscosity reducer and preparation method thereof

A viscosity reducer, oil-soluble technology, used in chemical instruments and methods, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as general viscosity reduction effect and strong pertinence, and achieve good oil solubility and easy operation. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

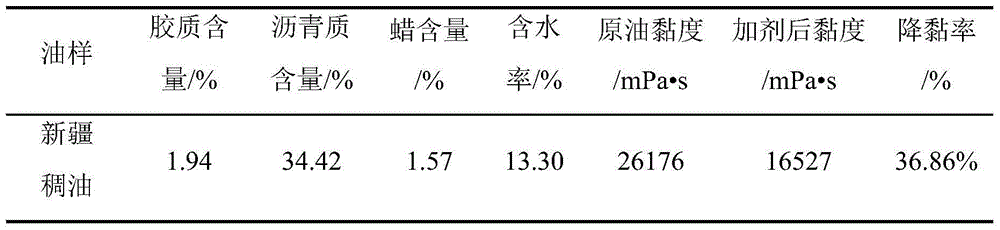

Examples

Embodiment 1

[0011] Add 1.2g of ethylenediamine, 2.4g of acetophenone and 7.69g of butyl acrylate in a four-necked flask equipped with a spherical condenser, a thermometer, a magnetic stirrer and an inlet pipe according to the molar percentage of the raw materials, and add 1 , 8.3g of 4-dioxane solvent, stirred and dissolved; then add 6g of formaldehyde solution with a mass percentage concentration of 30% to 40% and 9g of 1,4-dioxane in a constant pressure titration funnel Titration; put nitrogen protection in the four-necked flask and stir; heat, when the temperature rises to 60°C, start to drop the formaldehyde solution in the constant pressure funnel, control the drop rate at 1 drop / 4s, and wait for the reaction to proceed for 6 hours. Turn off heat. Then the above reaction solution was rotary evaporated under vacuum conditions to remove the solvent 1,4-dioxane and water; finally, the solution after rotary evaporation was purified with methanol four times to remove the upper liquid, and...

Embodiment 2

[0013] Add 1.2g of ethylenediamine, 2.4g of acetophenone and 7.69g of butyl acrylate in a four-necked flask equipped with a spherical condenser, a thermometer, a magnetic stirrer and an inlet pipe according to the molar percentage of the raw materials, and add 1 , 17.3g of 4-dioxane solvent, stir and dissolve; then add 6g of formaldehyde solution with a mass percentage concentration of 30% to 40% and 17.3g of 1,4-dioxane in a constant pressure titration funnel Wait for titration; put nitrogen protection in the four-necked flask and stir; heat, when the temperature rises to 60°C, start to drop the formaldehyde solution in the constant pressure funnel, control the dropping speed at 1 drop / 4s, and wait for the reaction to proceed for 6 hours , stop heating. Then the above reaction solution was rotary evaporated under vacuum conditions to remove the solvent 1,4-dioxane and water; finally, the solution after rotary evaporation was purified with methanol for 5 times, the upper liqui...

Embodiment 3

[0015] Add 1.2g of ethylenediamine, 2.4g of acetophenone and 7.69g of butyl acrylate in a four-necked flask equipped with a spherical condenser, a thermometer, a magnetic stirrer and an inlet pipe according to the molar percentage of the raw materials, and add 1 , 17.3g of 4-dioxane solvent, stir and dissolve; then add 6g of formaldehyde solution with a mass percentage concentration of 30% to 40% and 17.3g of 1,4-dioxane in a constant pressure titration funnel Wait for titration; put nitrogen protection in the four-necked flask and stir; heat, when the temperature rises to 70°C, start to drop the formaldehyde solution in the constant pressure funnel, control the dropping speed at 1 drop / 4s, and wait for the reaction to proceed for 7 hours , stop heating. Then the above reaction solution was rotary evaporated under vacuum conditions to remove the solvent 1,4-dioxane and water; finally, the solution after rotary evaporation was purified with methanol four times to remove the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com