Preparation method and application of allylic ester resin composite glass fiber photosensitive resin used for UV-curing 3D printing

A technology of allyl ester resin and glass fiber, which is used in the field of allyl for light-curing 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

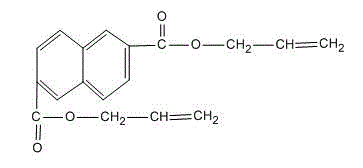

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: In the 10L glass fiber reinforced plastic mixing kettle that stirrer is housed, add viscosity and be 500-600 Pa.s

[0079] P DAP pre-polymerization solution 2.1Kg, then add E-glass fiber 3.9Kg, 1-hydroxycyclohexyl acetophenone 180g.

[0080] Stir and mix evenly at room temperature, which is a prepared photosensitive resin. With this photosensitive resin as material,

[0081] Use Shaanxi Hengtong Intelligent Machine Co., Ltd. SPS250J laser rapid prototyping machine to make some parts.

[0082] After the prepared photosensitive resin is cured by ultraviolet light, the warpage factor evaluation method is the second

[0083] The method determined by the first (1991) International Conference on Rapid Prototyping. The measured warpage factor CF(6)=0.1%,

[0084] CF(11)=0.5%. Tested according to GB / T3398, GB / T1040 and GB / T1634 test methods, tensile strength

[0085] 350MPa, tensile modulus 19700 MPa, heat distortion temperature 175 ℃.

Embodiment 2

[0086] Embodiment 2: In the 10L glass fiber reinforced plastics mixing kettle that stirrer is housed, adding viscosity is 500-600 P of Pa.s DAP pre-polymerization liquid 3.0Kg, then add E-glass fiber 3.0Kg, 1-hydroxycyclohexyl acetophenone 210g. Stir and mix evenly at room temperature, which is a prepared photosensitive resin. Using this photosensitive resin as material, some parts were made by using SPS250J laser rapid prototyping machine of Shaanxi Hengtong Intelligent Machine Co., Ltd.

[0087] After the prepared photosensitive resin is cured by ultraviolet light, the warpage factor evaluation method is the second

[0088] The method determined by the first (1991) International Conference on Rapid Prototyping. The measured warpage factor CF(6)=0.2%,

[0089] CF(11)=0.7%. Tested according to GB / T3398, GB / T1040 and GB / T1634 test methods, Rockwell hardness 124H, tensile strength 320MPa, tensile modulus 18200 MPa, heat distortion temperature 163 ℃

Embodiment 3

[0090] Embodiment 3: in the 10L glass fiber reinforced plastics mixing kettle that stirrer is housed, adding viscosity is 500-600 Pa.s

[0091] P DAP prepolymerization solution 3.9Kg, then add E-glass fiber 2.1Kg, 1-hydroxycyclohexyl acetophenone 270g.

[0092] Stir and mix evenly at room temperature, which is a prepared photosensitive resin. With this photosensitive resin as material,

[0093] Use Shaanxi Hengtong Intelligent Machine Co., Ltd. SPS250J laser rapid prototyping machine to make some parts.

[0094] After the prepared photosensitive resin is cured by ultraviolet light, the warpage factor evaluation method is the second

[0095] The method determined by the first (1991) International Conference on Rapid Prototyping. The measured warpage factor CF(6)=0.2%,

[0096] CF(11)=0.8%. Tested according to GB / T3398, GB / T1040 and GB / T1634 test methods, Rockwell hardness

[0097] 118H, tensile strength 294MPa, tensile modulus 16000 MPa, heat distortion temperature 157...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com