Rubber-plastic blend composition, dynamically vulcanized thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, dynamic vulcanization technology, applied in the field of thermoplastic elastomer and its preparation, rubber-plastic blending composition, can solve the problems of limited processing performance, poor mechanical properties and wear resistance, and achieve low processing temperature and low processing The effect of temperature and process simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

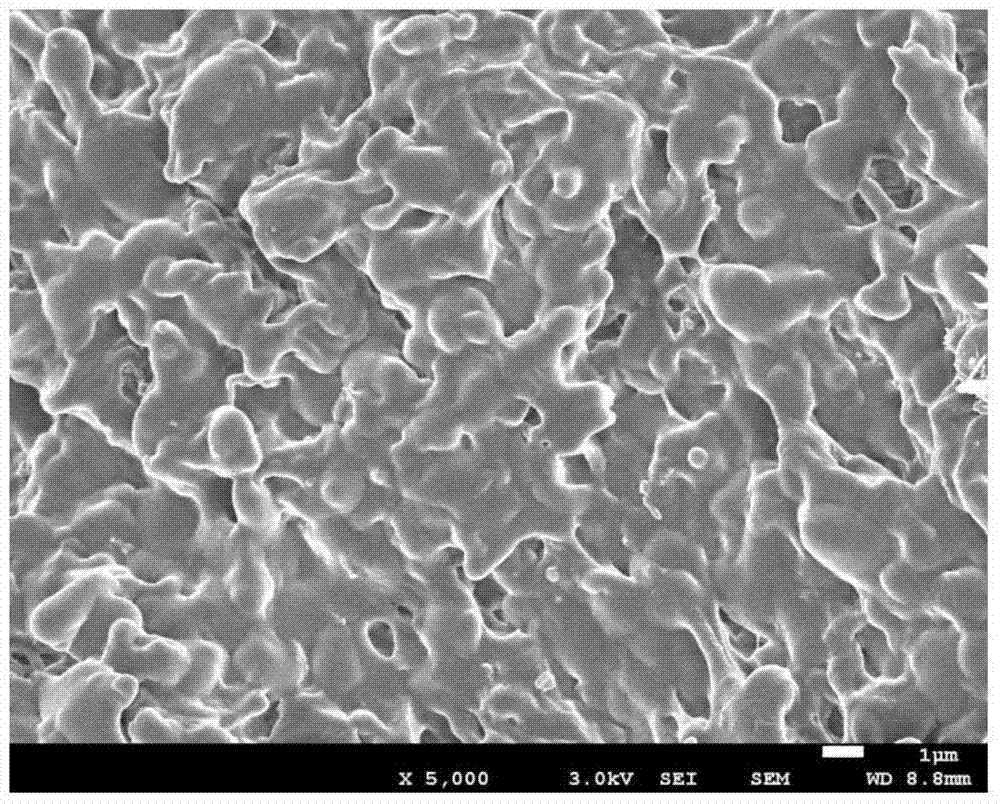

Embodiment 1

[0065] This embodiment provides a poly-1-butylene / EPDM rubber dynamically vulcanized thermoplastic elastomer, its components and its preparation method are as follows:

[0066] Raw materials include: 70 parts by weight of EPDM rubber, 30 parts by weight of poly-1 butene, 35 parts by weight of carbon black, 3.5 parts by weight of zinc oxide, 0.7 parts by weight of stearic acid, 0.7 parts by weight of di Tetramethylthiuram sulfide, the dibenzothiazole disulfide of 0.35 parts by weight, the sulfur of 1.4 parts by weight;

[0067] The preparation method comprises the following steps:

[0068] (1) Add 70 parts by weight of EPDM rubber, 35 parts by weight of carbon black, 3.5 parts by weight of zinc oxide, 0.7 parts by weight of stearic acid, and 0.7 parts by weight of tetramethyl qiuran disulfide in the internal mixer Mu, 0.35 parts by weight of dibenzothiazole disulfide, set the temperature of the internal mixer to 100°C, the discharge temperature to 150°C, the rotation speed to ...

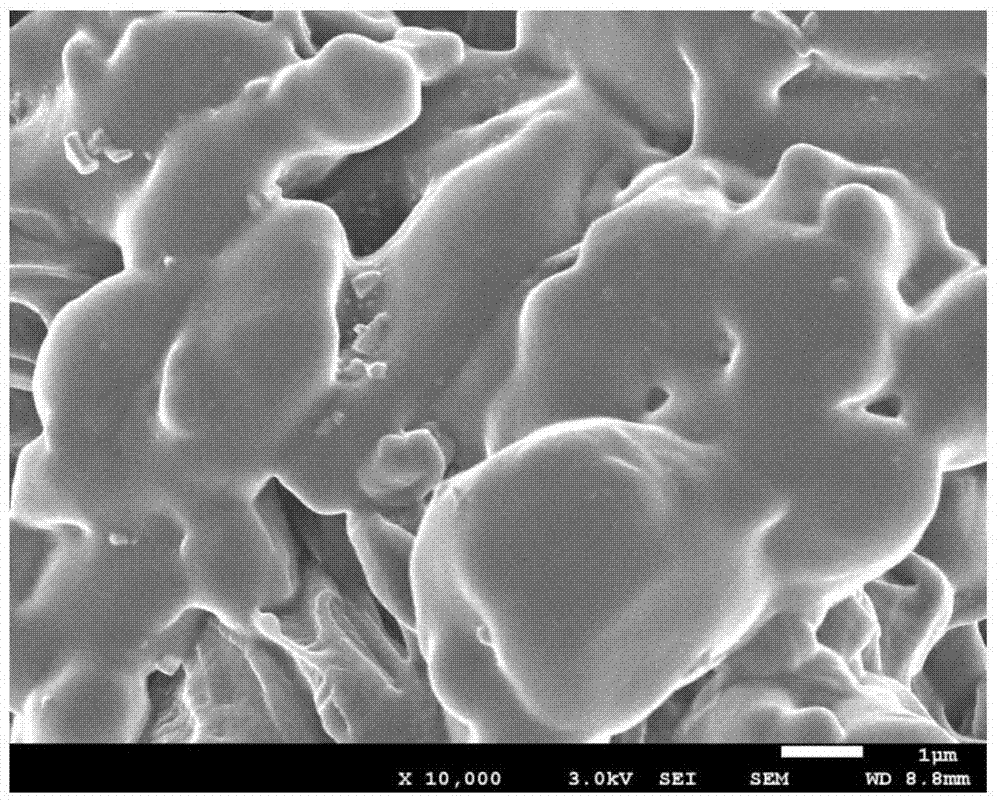

Embodiment 2

[0073] This embodiment provides a poly-1-butylene / EPDM rubber dynamically vulcanized thermoplastic elastomer, its components and its preparation method are as follows:

[0074] Raw materials include: 60 parts by weight of EPDM rubber, 40 parts by weight of poly-1 butene, 30 parts by weight of carbon black, 3 parts by weight of zinc oxide, 0.6 parts by weight of stearic acid, 0.6 parts by weight of Tetramethylthiuram sulfide, the dibenzothiazole disulfide of 0.3 parts by weight, the sulfur of 1.2 parts by weight;

[0075] The preparation method comprises the following steps:

[0076] (1) Add 60 parts by weight of EPDM rubber, 30 parts by weight of carbon black, 3 parts by weight of zinc oxide, 0.6 parts by weight of stearic acid, and 0.6 parts by weight of tetramethyl qiuran disulfide in the internal mixer Mu, 0.3 parts by weight of dibenzothiazole disulfide, set the temperature of the internal mixer to 100°C, the discharge temperature to 150°C, the rotation speed to 72r / min, ...

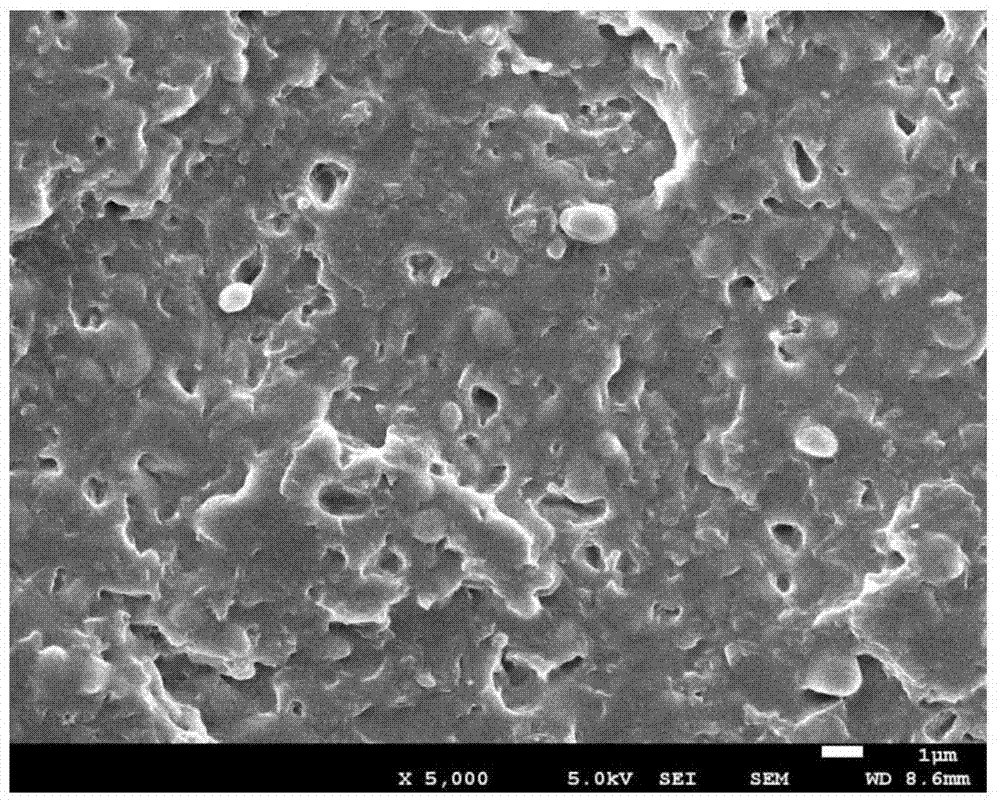

Embodiment 3

[0081] This embodiment provides a poly-1-butylene / EPDM rubber dynamically vulcanized thermoplastic elastomer, its components and its preparation method are as follows:

[0082] The raw materials include: 50 parts by weight of EPDM rubber, 50 parts by weight of poly-1 butene, 25 parts by weight of carbon black, 2.5 parts by weight of zinc oxide, 0.5 parts by weight of stearic acid, 0.5 parts by weight of di Tetramethylthiuram sulfide, the dibenzothiazole disulfide of 0.25 parts by weight, the sulfur of 1 part by weight;

[0083] The preparation method comprises the following steps:

[0084] (1) Add 50 parts by weight of EPDM rubber, 25 parts by weight of carbon black, 2.5 parts by weight of zinc oxide, 0.5 parts by weight of stearic acid, and 0.5 parts by weight of tetramethyl qiuran disulfide in the internal mixer Mu, 0.25 parts by weight of dibenzothiazole disulfide, set the temperature of the internal mixer to 100°C, the discharge temperature to 150°C, the rotation speed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com