Crateva unilocalaris Buch. polysaccharide extraction and purification method and application of crateva unilocalaris Buch. polysaccharide

The technology of a polysaccharide extraction and purification method, which is applied in the field of extraction and purification of polysaccharide from cabbage, can solve problems such as research on the extraction process of cabbage polysaccharide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] 1. Materials, reagents and equipment

[0029] The tender stems and leaves of tree head vegetables are collected from Yunlongjian Scenic Area in Lianyungang City; ethanol, anhydrous ether, acetone, sulfuric acid, phenol, glucose, ascorbic acid (VC), tert-butylhydroquinone (TBHQ), pyrogallol, Salicylic acid, Tris (Tris), potassium ferricyanide, trichloroacetic acid, ferric chloride, and ferrous sulfate are all analytically pure from Shanghai Sinopharm Group. UV-2550 ultraviolet spectrophotometer (Shimadzu Corporation); RE-5285A rotary evaporator (Shanghai Yarong Biochemical Instrument Factory); DHG-9240A electric constant temperature blast drying oven (Shanghai Yiheng Technology Co., Ltd.); TDL-4 desktop centrifuge (Shanghai Anting Scientific Instrument Factory).

[0030] 2. The method for extracting and purifying polysaccharides from tree head vegetable, the specific steps are as follows:

[0031] Take the tree head vegetable and carry out microwave dehydration at room...

specific Embodiment 2

[0032] Determination of optimal extraction conditions

[0033] 1. Single factor test

[0034]Select extraction temperature (60-100°C), extraction time (2-4h), liquid-to-solid ratio (10-30:1mL / g), particle size (20-80 mesh) to conduct a single factor test.

[0035] 1.1 The effect of extraction temperature on the extraction rate of crude polysaccharides

[0036] Under the conditions of extraction time 3h, liquid-solid ratio 25:1, and extraction once, the influence of different extraction temperatures on the extraction rate of polysaccharides was investigated, and the results were as follows figure 1 shown. With the increase of extraction temperature, the extraction rate of crude polysaccharides from Arboria arborifolia increased rapidly, and when the temperature reached 80°C, the extraction rate of polysaccharides increased slowly, so the extraction temperature was preferably 90°C.

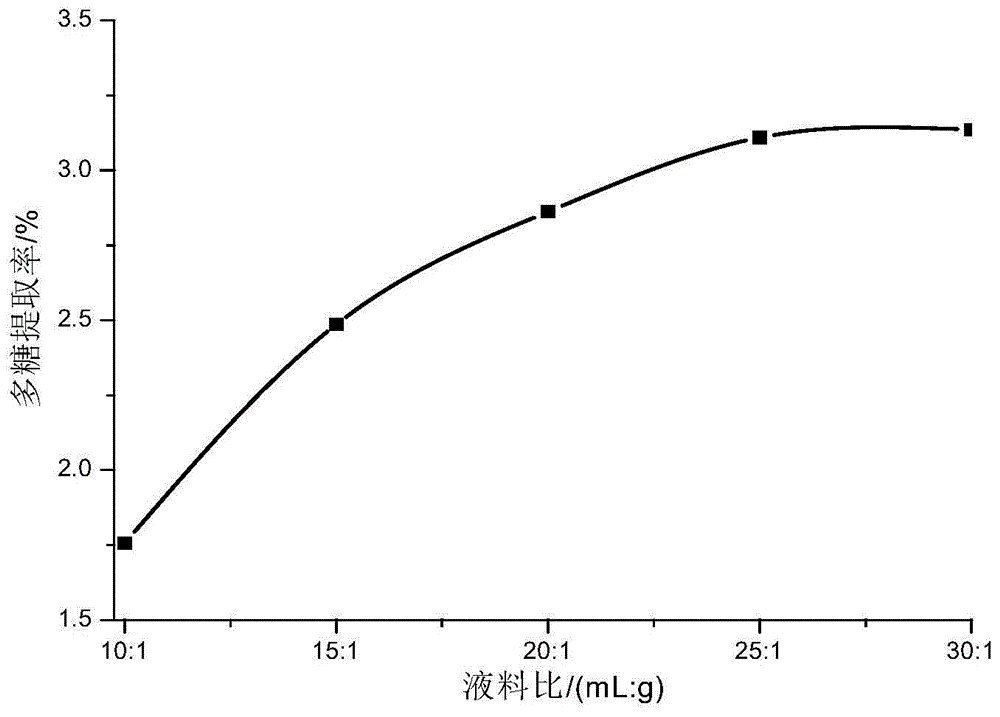

[0037] 1.2 The effect of liquid-solid ratio on the extraction rate of crude polysaccharides ...

specific Embodiment 3

[0055] Determination of Antioxidant Activity of Barkweed Polysaccharides

[0056] The extracted crude polysaccharides of barkweed were dissolved in water and purified repeatedly by Sevag method to remove impurities such as protein and nucleic acid until there were no characteristic absorption peaks at 260 nm and 280 nm by ultraviolet detection. Then the precipitate was washed three times with acetone and ethyl acetate, and dried at low temperature to obtain the polysaccharide product of barkweed with a purity of 99.2%, which was used for the determination of antioxidant activity. With vitamin C (V C ) and TBHQ as a control, the reducing power, hydroxyl radical scavenging rate and superoxide anion free radical scavenging rate were measured on the purified polysaccharides of barkweed.

[0057] 1. The reducing ability of tree head vegetable polysaccharide

[0058] By test results Figure 5 It can be seen that within the range of the experimental mass concentration, the reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com