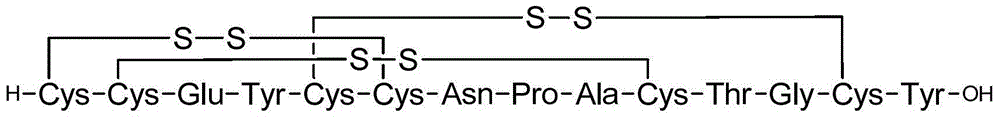

Preparation method for linaclotide

A technology of linaclotide and protecting group, which is applied in the field of preparation of linaclotide, can solve the problems of a large amount of time for separation and purification, consumption of large solvent and raw materials, inconvenience of industrial production, etc., and achieves simple operation and high total yield , the effect of improving the yield of cyclization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1 WANG resin (1.28mmol / g, 640mg), tert-butyl (tBu) protected Fmoc tyrosine (Fmoc-Tyr(tBU)-OH) (689.33mg, 1.5mmol) and DIPEA (414μL, 5mmol) , HBTU (113.77mg, 3mmol) was placed in a reaction flask, added DMF (20mL) to dissolve, and stirred for 6-12 hours. After the reaction is complete, let it stand still, drain the DMF, wash the resin with DMF to obtain a yellow resin, then use hexahydropiperidine-DMF (1 / 4; 20mL) to remove the protective group, and react for 20-40 minutes. The synthetic method is carried out with reference to the same steps.

[0051] In step 2, the WANG resin reacted with tyrosine was directly mixed with trityl (Trt)-protected Fmoc cysteine (Fmoc-Cys(Trt)-OH) (878.58 mg, 1.5 mmol) and DIPEA (414 μL, 5mmol), HBTU (113.77mg, 3mmol) was placed in a reaction flask, DMF (20mL) was added to dissolve, and stirred for 6-12 hours. After the reaction is complete, let it stand still, drain the DMF, wash the resin with DMF to obtain a yellow resin, then use...

Embodiment 2

[0067] Step 1 WANG resin (1.28mmol / g, 640mg), tert-butyl (tBu) protected Fmoc tyrosine (Fmoc-Tyr(tBU)-OH) (689.33mg, 1.5mmol) and DIPEA (414μL, 5mmol) , HBTU (113.77mg, 3mmol) was placed in a reaction flask, added DMF (20mL) to dissolve, and stirred for 6-12 hours. After the reaction is complete, let it stand still, drain the DMF, wash the resin with DMF to obtain a yellow resin, then use hexahydropiperidine-DMF (1 / 4; 20mL) to remove the protective group, and react for 20-40 minutes. The synthetic method is carried out with reference to the same steps.

[0068] In step 2, the WANG resin reacted with tyrosine was directly mixed with trityl (Trt)-protected Fmoc cysteine (Fmoc-Cys(Trt)-OH) (878.58 mg, 1.5 mmol) and DIPEA (414 μL, 5mmol), HBTU (113.77mg, 3mmol) was placed in a reaction flask, DMF (20mL) was added to dissolve, and stirred for 6-12 hours. After the reaction is complete, let it stand still, drain the DMF, wash the resin with DMF to obtain a yellow resin, then use...

Embodiment 3

[0084] Step 1 WANG resin (1.28mmol / g, 640mg), tert-butyl (tBu) protected Fmoc tyrosine (Fmoc-Tyr(tBU)-OH) (689.33mg, 1.5mmol) and DIPEA (414μL, 5mmol) , HBTU (113.77mg, 3mmol) was placed in a reaction flask, added DMF (20mL) to dissolve, and stirred for 6-12 hours. After the reaction is complete, let it stand still, drain the DMF, wash the resin with DMF to obtain a yellow resin, then use hexahydropiperidine-DMF (1 / 4; 20mL) to remove the protective group, and react for 20-40 minutes. The synthetic method is carried out with reference to the same steps.

[0085] In step 2, the WANG resin reacted with tyrosine was directly mixed with trityl (Trt)-protected Fmoc cysteine (Fmoc-Cys(Trt)-OH) (878.58 mg, 1.5 mmol) and DIPEA (414 μL, 5mmol), HBTU (113.77mg, 3mmol) was placed in a reaction flask, DMF (20mL) was added to dissolve, and stirred for 6-12 hours. After the reaction is complete, let it stand still, drain the DMF, wash the resin with DMF to obtain a yellow resin, then use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com