Tin-radical welding flux/copper particle composite welding flux capable of forming high-temperature welding spots rapidly at low temperature

A composite welding and copper particle technology, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of slow formation of full IMC solder joints and difficulty in actual production of reaction efficiency, so as to avoid premature failure. , The effect of strong versatility of raw materials and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The tin-based solder / copper particle composite solder of the present embodiment is made of commercially available No. 5 Sn3.0Ag0.5Cu (i.e. Sn96.5wt%: Ag3.0wt%: Cu0.5wt%) tin-based solder powder (size 15 μm-25 μm) ), copper microparticle powder (size 1μm-2.5μm), solder paste ("YIKST" brand CR135 rosin type solder paste), the total mass is 50g, and its components are calculated by mass fraction:

[0038] Tin based solder powder 56%

[0039] Copper particle powder 34%

[0040] Solder paste 10%

[0041] First, mechanically stir the commercially available rosin-type solder paste at a speed of 30r (rotation) / min (minute) for 30min (minutes), then slowly add tin-based solder powder and copper particle powder into the solder paste at the same time, add The speed is 10g / min, and the stirring is continued for 1 hour to obtain a uniform mixed tin-based solder / copper particle composite solder paste.

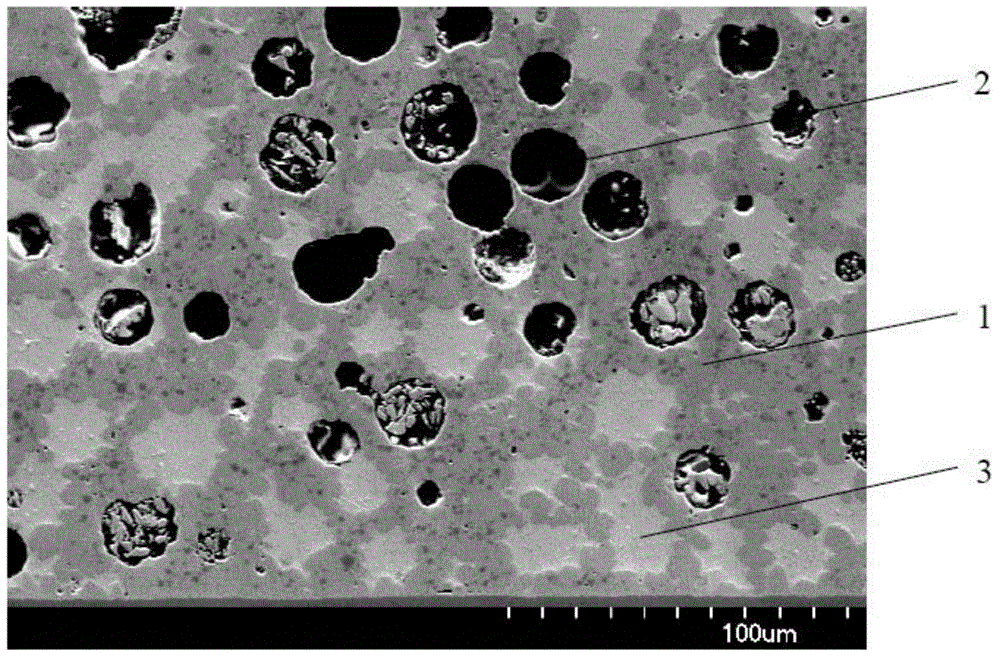

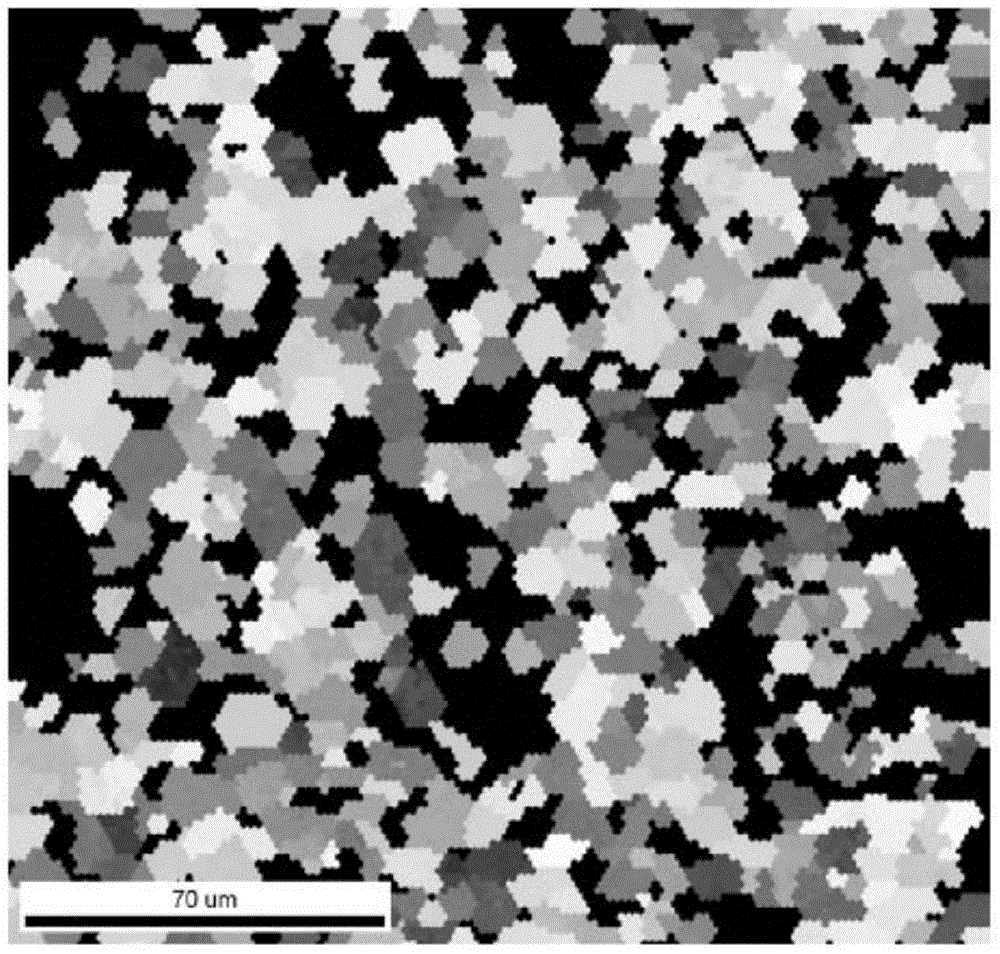

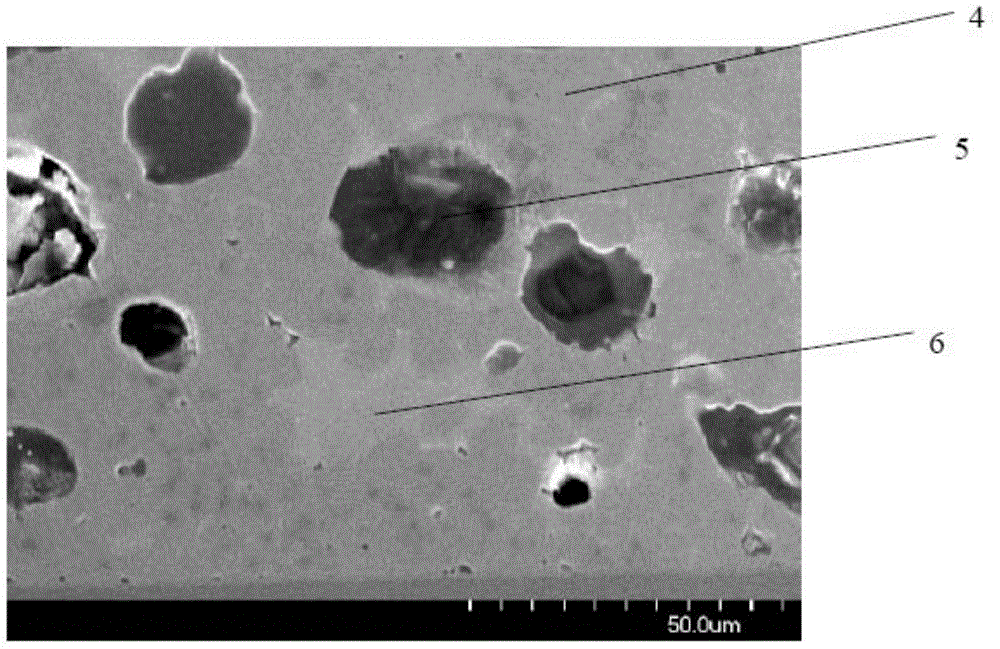

[0042] Apply the tin-based solder / copper particle composite solder paste on th...

Embodiment 2

[0044] The tin-based solder / copper particle composite solder of the present embodiment is made of commercially available No. 6 Sn3.0Ag0.5Cu (i.e. Sn96.5wt%: Ag3.0wt%: Cu0.5wt%) tin-based solder powder (5-15 μm) , copper particle powder (1-2.5μm), solder paste ("YIKST" brand CR138 rosin type solder paste), the total mass is 50g, and its components are calculated by mass fraction:

[0045] Tin-based solder powder 54%

[0046] Copper particle powder 36%

[0047] Solder paste 10%

[0048] First, mechanically stir the commercially available rosin-type solder paste at a speed of 30r (rotation) / min (minute) for 30min (minutes), then slowly add tin-based solder powder and copper particle powder into the solder paste at the same time, add The speed is 10g / min, and the stirring is continued for 1 hour to obtain a uniform mixed tin-based solder / copper particle composite solder paste.

[0049] Apply the tin-based solder / copper particle composite solder on the electroplated bare copper ...

Embodiment 3

[0051] The tin-based solder / copper particle composite solder of the present embodiment is made of commercially available No. 4 Sn0.7Cu (i.e. Sn99.3wt%: Cu0.7wt%) solder powder (20-38 μm), copper particle powder (1-2.5 μm) , solder paste ("YIKST" brand JM01 rosin-type solder paste), the total mass is 50g, and its components are calculated as follows in mass fraction:

[0052] Tin based solder powder 50%

[0053] Copper particle powder 38%

[0054] Solder paste 12%

[0055] First, mechanically stir the commercially available rosin-type soldering paste at a speed of 30r / min for 30min, then slowly add tin-based solder powder and copper particle powder into the soldering paste at the same time at a speed of 30g / min, and continue stirring for 1 hours to obtain a mixed solder paste that is mixed evenly.

[0056] Apply the tin-based solder / copper particle composite solder on the electroplated bare copper pad to form a sandwich structure of copper pad / composite solder paste / copper p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com