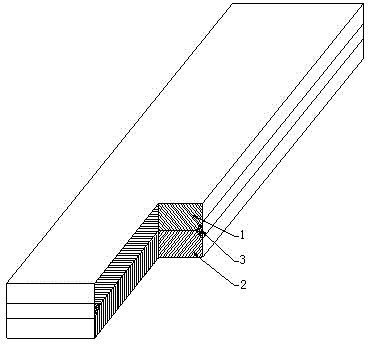

Abrasion resistant steel and low-carbon steel dissimilar metal submerged-arc welding technology

A welding process and dissimilar metal technology, applied in the field of dissimilar metal welding process, to achieve the effect of reducing production cost, ensuring normal production and high weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

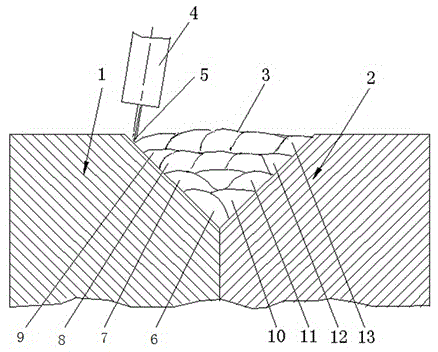

[0046] The submerged arc welding process of wear-resistant steel and low carbon steel dissimilar metals, the welding schematic diagram is as follows figure 2 shown, including the following steps:

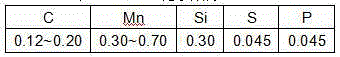

[0047] Step (1), choose dry, oil-free, rust-free ordinary carbon steel welding wire 5, and keep the welding wire dry, oil-free, and rust-free in the welding area; choose alkaline flux as the flux, and the flux must be at 300°C before welding Bake for 2 hours;

[0048] In step (2), under the conditions of welding voltage of 25V, welding current of 250A, welding speed of 0.2m / min, groove depth of 10mm, groove angle of 120°, and interlayer temperature of 40°C, wear-resistant steel Full welding with the low carbon steel groove, and the connection method is DC positive connection during welding;

[0049] Step (3), during the first welding, the first welding 6 is carried out on the low carbon steel side 1, and the second welding 10 is carried out directly on the wear-resistant steel 2 ...

Embodiment 2

[0056] The submerged arc welding process of wear-resistant steel and low carbon steel dissimilar metals, the welding schematic diagram is as follows figure 2 shown, including the following steps:

[0057] Step (1), choose dry, oil-free, rust-free ordinary carbon steel welding wire, and keep the welding wire dry, oil-free, and rust-free in the welding area; choose alkaline flux as the flux, and the flux must be baked at 400 ° C for 1 Hour;

[0058] In step (2), under the conditions of welding voltage of 45V, welding current of 550A, welding speed of 1.0m / min, groove depth of 15mm, groove angle of 100°, and interlayer temperature of 120°C, wear-resistant steel Full welding with the low carbon steel groove, and the connection method is DC positive connection during welding;

[0059] Step (3), during the first welding, the first welding 6 is carried out on the low carbon steel side 1, and the second welding 10 is carried out directly on the wear-resistant steel 2 side after the...

Embodiment 3

[0066] The submerged arc welding process of wear-resistant steel and low carbon steel dissimilar metals, the welding schematic diagram is as follows figure 2 shown, including the following steps:

[0067] Step (1), choose dry, oil-free, rust-free ordinary carbon steel welding wire, and keep the welding wire dry, oil-free, and rust-free in the welding area; choose alkaline flux as the flux, and the flux must be baked at 350°C for 1.5 hours before welding. Hour;

[0068] In step (2), under the conditions of welding voltage of 35V, welding current of 400A, welding speed of 0.5m / min, groove depth of 20mm, groove angle of 90°, and interlayer temperature of 80°C, wear-resistant steel Full welding with the low carbon steel groove, and the connection method is DC positive connection during welding;

[0069] Step (3), during the first welding, the first welding 6 is carried out on the low carbon steel side 1, and the second welding 10 is carried out directly on the wear-resistant st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com