Core body structure for high-pressure-resistant heat exchanger

A heat exchanger, high-pressure technology, applied in the direction of laminated components, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of broken partitions, insufficient weld strength, small contact surface, etc., to reduce the risk of leakage , The effect of increasing weld strength and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

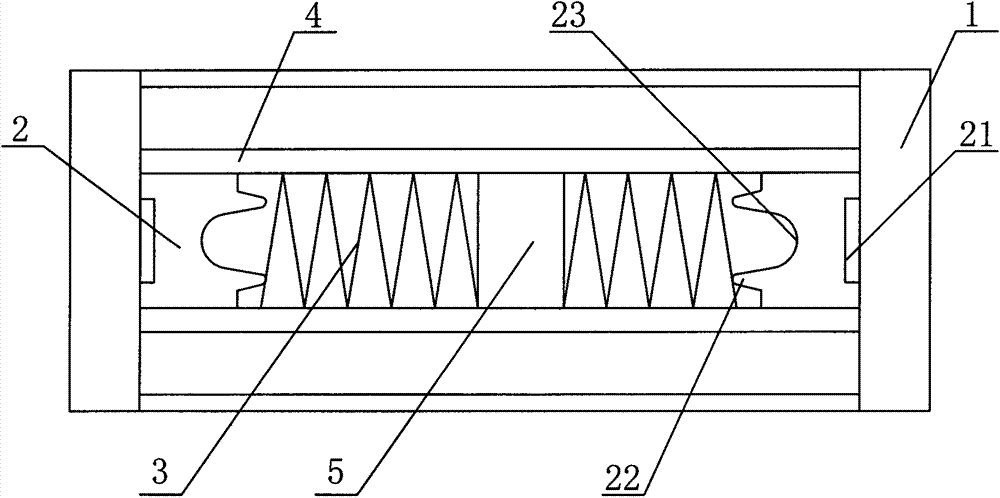

[0010] Such as figure 1 As shown, the two ends of the core body of the present invention have a pair of sealing heads 1 and several pairs of sealing strips 2 respectively, the sealing strips 2 are fixedly connected with the sealing heads 1, and the upper and lower sides of the sealing strips 2 are fixedly connected with the partition plate 4, and each pair of A number of reinforcing ribs 5 are evenly distributed between the two sealing strips 2 in the seal 2, and there are fins 3 between the reinforcing ribs 5 and between the reinforcing ribs 5 and the sealing strip 2, and the reinforcing ribs 5 are fixedly connected with the upper and lower partitions 4 In one body, the rib 5 divides the fin 3 between the two seals 2 into several parts, which not only makes the fin 3 more stable, but also increases the strength of the partition 4 to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com