Floatation and purification method for quartz stone pulverized through heating power

A purification method, quartz technology, applied in flotation, solid separation, grain processing, etc., to reduce hardness, improve grinding efficiency, and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

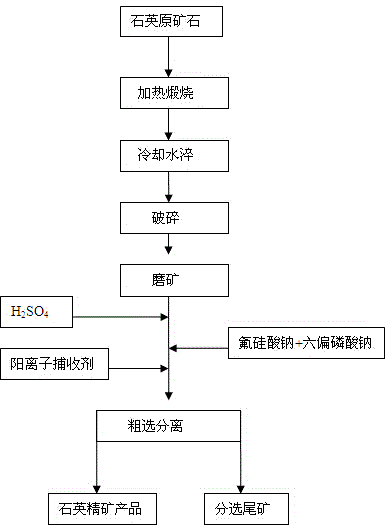

[0030] The mass content of quartz in the raw ore of a quartz mine is 98.72%, Al 2 o3 The mass content of the ore is 1.08%. The main impurity minerals in the ore are aluminosilicates such as potassium feldspar, according to figure 1 The flotation process and conditions for flotation.

[0031] (1) Put the bulk quartz ore with a diameter of 50~100mm into a muffle furnace, calcinate at 600°C for 120 minutes, and then use clean water with a temperature lower than 80°C to spray and quench the calcined quartz ore to obtain heat crushed quartz ore;

[0032] (2) Continue to crush and grind the thermally crushed quartz ore to a particle size of <150 μm, and add water to make a slurry with a mass concentration of 40%;

[0033] (3) Put the slurry into the flotation equipment for cationic collector flotation, and add H 2 SO 4 Adjust the pH value of the slurry to 2.0. After stirring for 2 minutes, add a mixing regulator at a rate of 10 mg per liter of slurry. The mixing regulator is a m...

Embodiment 2

[0036] The mass content of quartz in the raw ore of a quartz mine is 97.73%, Al 2 o 3 The mass content of the ore is 1.47%. The main impurity minerals in the ore are aluminosilicate minerals such as potassium feldspar and albite, that is, trace iron-containing minerals. figure 1 The flotation process and conditions for flotation.

[0037] (1) Put the bulk quartz ore with a diameter of 50~100mm into the tunnel kiln, calcinate at 800°C for 100 minutes, and then use clean water with a temperature lower than 80°C to quench the calcined quartz ore in a water bath to obtain thermally pulverized quartz ore;

[0038] (2) Continue to crush and grind the thermally crushed quartz ore to a particle size of <150 μm, and add water to make a slurry with a mass concentration of 50%;

[0039] (3) Put the slurry into the flotation equipment for cationic collector flotation, and add H 2 SO 4 Adjust the pH value of the slurry to 4.0. After stirring for 3 minutes, add a mixing regulator at 20...

Embodiment 3

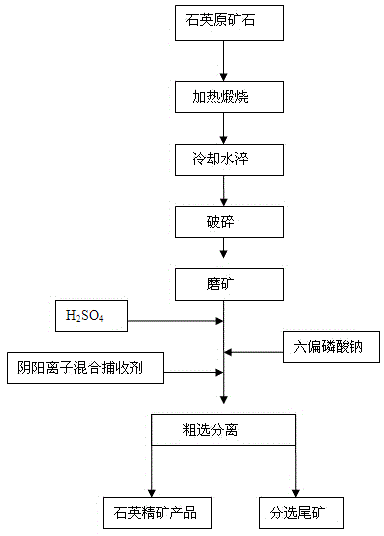

[0042] The mass content of quartz in the raw ore of a quartz mine is 96.74%, Al 2 o 3 The mass content of the ore is 1.73%. The main impurity minerals in the ore are aluminosilicate minerals such as potassium feldspar and albite, that is, trace iron-containing minerals. figure 2 The flotation process and conditions for flotation.

[0043] (1) Put the block quartz ore with a diameter of 50~120mm into the shaft kiln, calcinate at 1000°C for 30 minutes, and then use clean water with a temperature lower than 80°C to quench the calcined quartz ore in a water bath to obtain thermally pulverized quartz ore;

[0044] (2) Continue to crush and grind the thermally crushed quartz ore to a particle size of <150 μm, and add water to make a slurry with a mass concentration of 30%;

[0045] (3) Put the slurry into the flotation equipment for flotation with anion and cation collectors, and add H 2 SO 4 Adjust the pH value of the slurry to 2. After stirring for 2 minutes, add the regulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com