Synthetic method of high-performance one-dimensional nanostructure vanadium oxide lithium ion battery electrode material

A lithium vanadium oxide and nanostructure technology, applied in battery electrodes, vanadium oxide, nanotechnology, etc., to achieve the effect of simple synthesis method, high repeatability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First place 0.182g of V 2 o 5 Add it to one cavity of the lining of the high-temperature mixed hydrothermal reactor, and then add 0.378g of oxalic acid to another cavity of the lining;

[0038] Then add 5ml deionized water to the two chambers respectively;

[0039] Then seal the reactor and put it into an oven to heat up. When the temperature rises to 200-260°C, rotate the reactor to mix the reactants in the two inner cavities of the reactor and keep it warm for 2-24 hours;

[0040] Cool to room temperature after reaction finishes;

[0041] Finally, the obtained precipitate was washed several times with deionized water and absolute ethanol, and then dried at 80 °C for 10 h to obtain a metastable phase VO with good dispersibility. 2 (B) Powder.

[0042] Embodiment two:

Embodiment 2

[0044] First place 0.182g of V 2 o 5 Add it to one cavity of the lining of the high-temperature mixed hydrothermal reactor, and then add 0.378g of oxalic acid to another cavity of the lining;

[0045] Then add 5ml deionized water to the two chambers respectively;

[0046] Afterwards, seal the reactor and put it into an oven to heat up. When the temperature rises to 240°C, rotate the reactor to mix the reactants in the two cavities of the reactor and keep it warm for 24-48 hours;

[0047] Cool to room temperature after reaction finishes;

[0048] Finally, the obtained precipitate was washed several times with deionized water and absolute ethanol, and then dried at 80 °C for 10 h to obtain a metastable phase VO with good dispersibility. 2 (A) Powder.

[0049] Embodiment three:

Embodiment 3

[0051] First place 0.182g of V 2 o 5 Add it to one cavity of the lining of the high-temperature mixed hydrothermal reactor, and then add 0.378g of oxalic acid to another cavity of the lining;

[0052] Then add 5ml deionized water to the two chambers respectively;

[0053] Afterwards, seal the reactor and place it in an oven to heat up. When the temperature reaches 240°C, rotate the reactor so that the reactants in the two cavities of the reactor are mixed and kept warm for 1 hour;

[0054] Cool to room temperature after reaction finishes;

[0055] Finally, the obtained precipitate was washed several times with deionized water and absolute ethanol, and dried at 80 °C for 10 h to obtain a stable phase V with better dispersion 3 o 7 ·H 2 O powder.

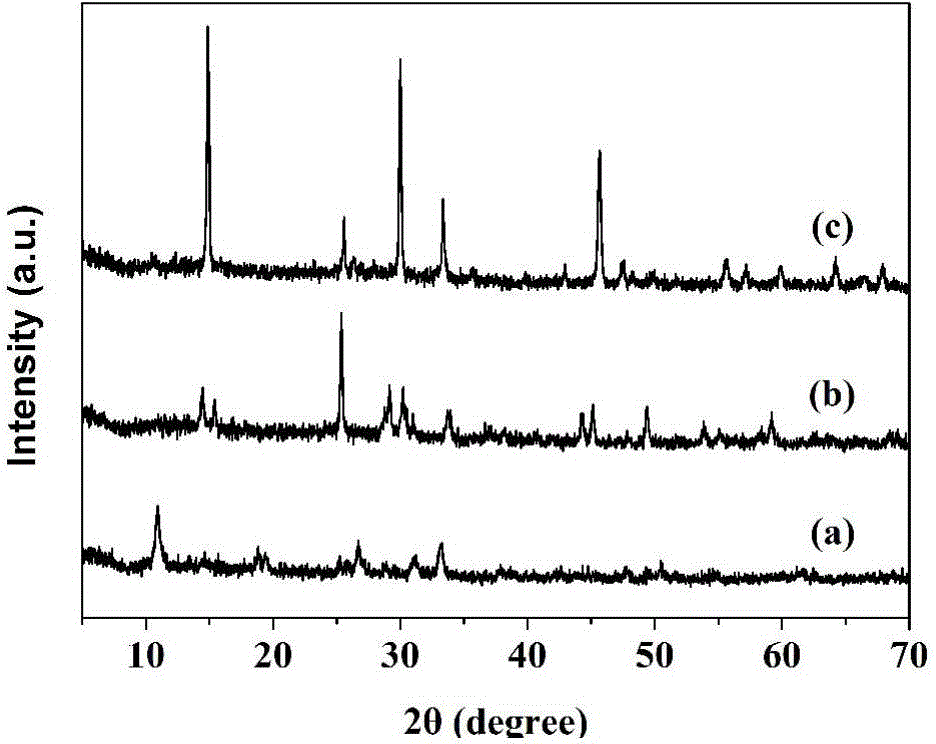

[0056] like figure 1 , figure 2 and image 3 shown, from figure 1 It is clearly seen in the XRD pattern that VO was synthesized under this experimental condition2 (B), VO 2 (A) and V 3 o 7 ·H 2 O three kinds of vanadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com