Electromagnetic sensing principle based inspection component of concrete reinforcement detector

A technology of concrete rebar and electromagnetic induction, applied in electromagnetic measuring device, electric/magnetic diameter measurement, using electromagnetic means, etc., can solve the problem that the quality of the test results of the concrete rebar detector cannot be guaranteed, and the traceability of the value of the concrete rebar detector cannot be realized. and transfer, inability to effectively control the uncertainty of measurement results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

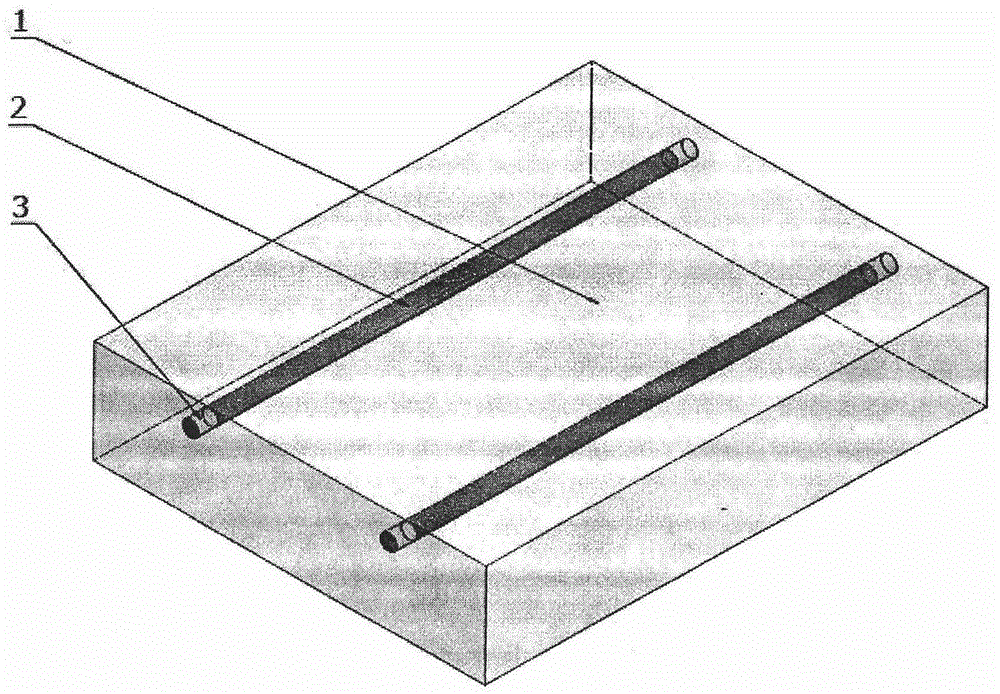

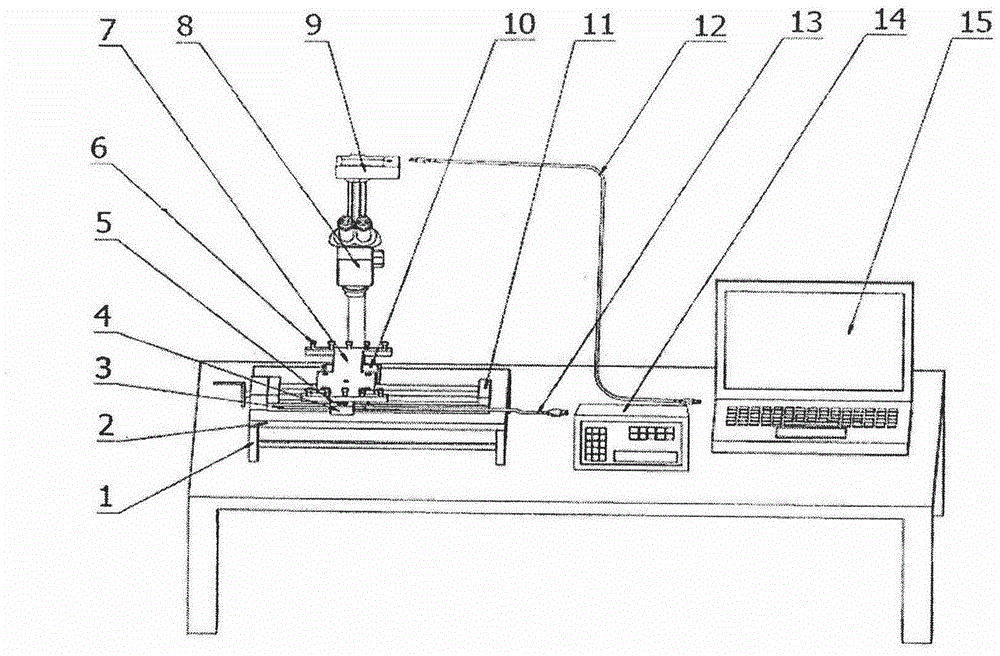

[0020] A metal rod position measuring device in a transparent material based on the principle of image recognition involved in the present invention is a testing device that uses "stereo microscope magnification—industrial camera imaging—image processing software recognition—grating ruler to collect data". The components of the device are shock-isolated optical platform support (1), optical flat plate (2), grating ruler (3), grating ruler reading head (4), grating ruler fixing part (5), fixed inspection component standard part (6 ), connection plate (7), stereo microscope (8), industrial camera (9), parallel light source (10), slide rail (11), industrial camera data cable (12), grating scale reading table data cable (13) , grating ruler reading table (14) and computer and image processing software (15). When inspecting the concrete steel bar detector based on the principle of electromagnetic induction, put the test member of the concrete steel bar detector based on the princip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com