Ground waste gas incineration flare device

A waste gas and ground technology, applied in incinerators, combustion chambers, combustion methods, etc., can solve the problems of small torch processing capacity, large investment, environmental pollution, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

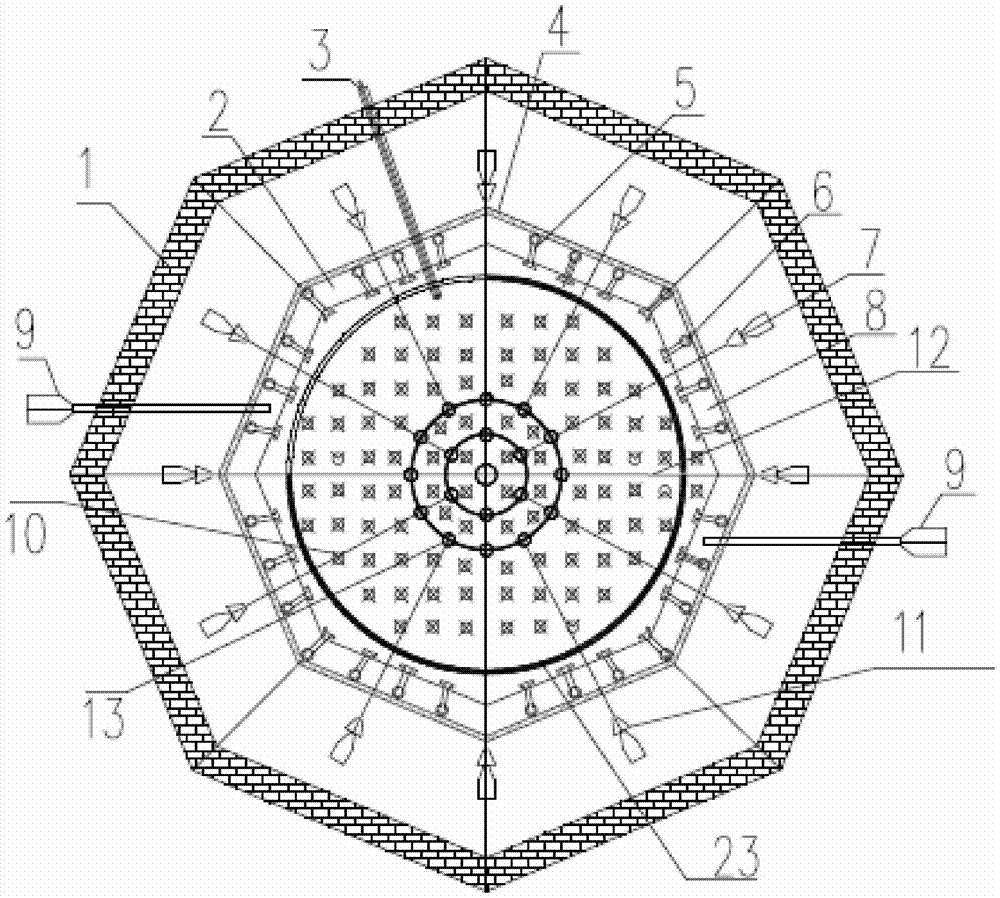

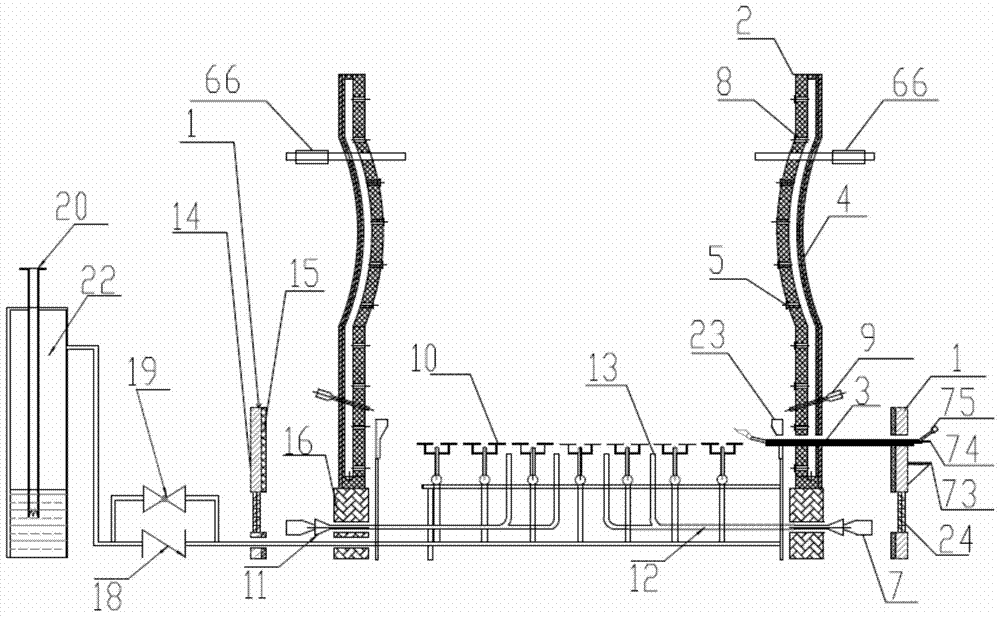

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0036] 1. Combustion tower with variable diamond structure (variable refers to the shape structure, which is quadrilateral, pentagonal, hexagonal, etc.; each side of the polygon can be equal or unequal): the purpose is to solve the difficulty of cylinder installation, The cost is high and the time is long; the on-site processing quality control is difficult; the changeable rhombus can be produced in the factory according to the needs, and can be assembled on site. The installation is simple and convenient, the time is short, the cost is low, and the quality control is convenient. The top view of the combustion tower is as follows Figure 4 and Figure 5 As shown, the plates are connected by flanges 81 .

[0037] 2. Design compressor and air storage tank:

[0038] Such as Figure 6 As shown, a compressor 60 , an air storage tank 61 and an air outlet 66 are included...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com