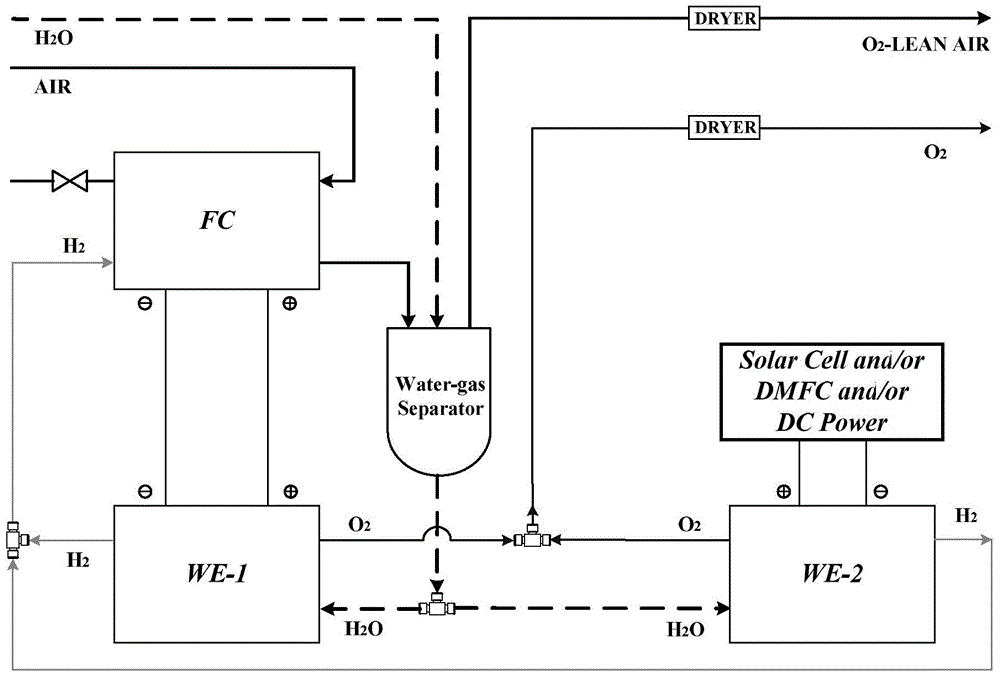

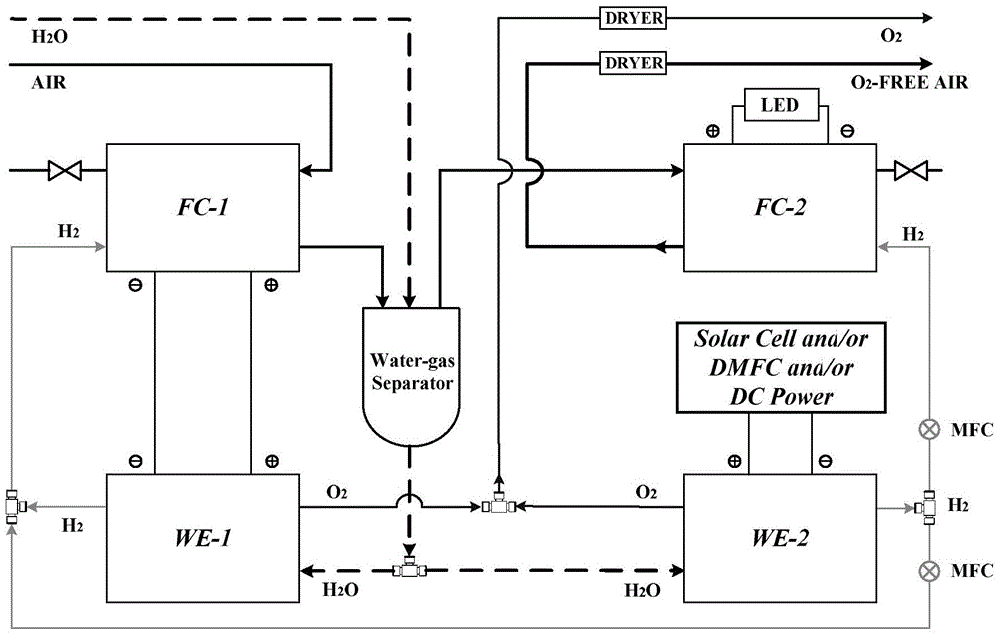

Electrochemistry method for preparing pure oxygen and poor-oxygen gas by oxygen-containing gas mixture

一种贫氧气体、电化学的技术,应用在制备纯氧及贫氧气体领域,能够解决电解水能耗高、消耗等问题,达到连续运行稳定可靠、系统使用安全、能量效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

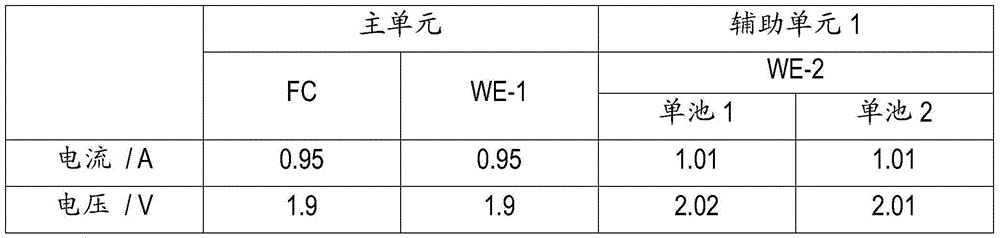

Embodiment 1

[0037] Get Nafion212 film (EW=1052g / mol SO3H ) 40cm 2 , add 20ml of N-methyl-2-pyrrolidone and 10ml of isopropanol and heat to dissolve to prepare a perfluorosulfonic acid solution. Cast the perfluorosulfonic acid solution on a flat plate, heat it at 70°C for 10 hours, then raise the temperature to 77°C and heat it for 12 hours. After the solvent is basically volatilized, heat-treat it in a vacuum oven at 130°C for 1 hour to form a base film with a thickness of 18 μm. Polymer electrolyte membrane for fuel cell and 50μm solid electrolyte water electrolysis cell membrane.

[0038] Using SGL carbon paper, PTFE emulsion, XC-72 carbon powder, 5% (DuPont) solution and 20% Pt / C catalyst to prepare electrodes, in which The mass ratio of resin to C was 0.8. Negative electrode Pt load is 0.3mg / cm 2 , the positive Pt load is 0.5mg / cm 2 . Press 5cm 2 The operating conditions of the MEA three-in-one hydraulic press are 160°C, micro-pressure pre-compression for 1 minute, then incr...

Embodiment 2

[0046] Weigh 60 g of sulfonated polysulfone (60% sulfonation degree), add 10 ml of N,N-dimethylacetamide and 5 ml of diethyl ether and n-butanol and heat to dissolve. Stretch the porous polytetrafluoroethylene membrane with a thickness of 90 μm, a pore diameter of 0.09 μm, and a porosity of 90% on a stainless steel frame, pour the sulfonated polysulfone solution, heat at 60°C for 24 hours, and then heat up to 75°C for 10 Hours, after the solvent is basically volatilized, heat treatment in a vacuum oven at 100°C for 2 hours to form a base film. A solid electrolyte water electrolysis cell membrane with a thickness of 50 μm was prepared.

[0047] Get Nafion212 film (EW=1052g / mol SO3H ) 30cm 2 , add 10ml of N-methyl-2-pyrrolidone and 25ml of isopropanol and heat to dissolve to prepare a perfluorosulfonic acid solution. Cast the perfluorosulfonic acid solution on a flat plate, heat it at 65°C for 10 hours, then raise the temperature to 78°C and heat it for 14 hours. After the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com