Aluminum and aluminum alloy water-based cutting fluid

A cutting fluid, water-based technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of high cost, fast volatilization, low flash point, etc., and achieve the effect of safe use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

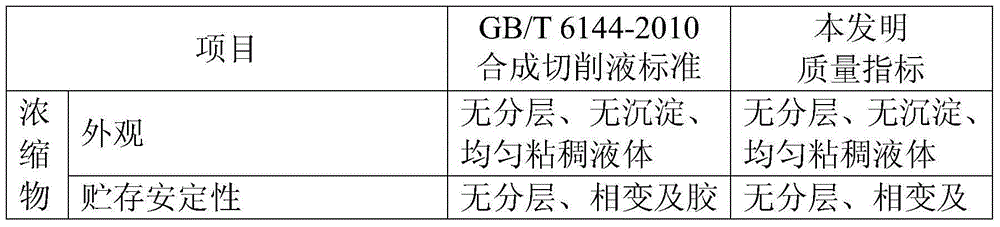

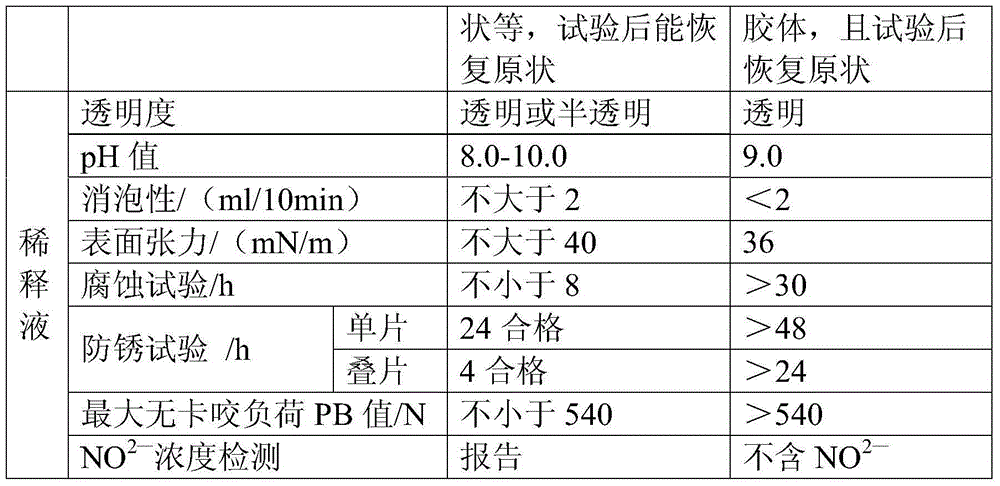

Image

Examples

experiment example 1

[0017] The formula of a water-based cutting fluid for aluminum and its alloys is: 9% triethanolamine borate, 2% triethanolamine oleate, 14% imidazole phosphoramide, 2% NSH, 14% fatty alcohol polyoxyethylene ether %, borax 2%, simethicone 10%, sodium benzoate 2%; the balance is supplemented by water. The components need to be dissolved in water respectively before mixing. After mixing, further dilute. The dilution ratio is 1 liter of the above cutting fluid plus 19 liters of water. After adding water, stir evenly for use.

experiment example 2

[0019] The formula of an aluminum and its alloy water-based cutting fluid is: 7% triethanolamine borate, 3% triethanolamine oleate, 10% imidazole phosphoramide, 3% NSH, 16% fatty alcohol polyoxyethylene ether %, borax 2%, simethicone 10%, sodium benzoate 2%; the balance is supplemented by water. The components need to be dissolved in water respectively before mixing. After mixing, further dilute. The dilution ratio is 1 liter of the above cutting fluid plus 19 liters of water. After adding water, stir evenly for use.

experiment example 3

[0021] The formula of an aluminum and its alloy water-based cutting fluid is: 7% triethanolamine borate, 3% triethanolamine oleate, 12% imidazole phosphoramide, 2% NSH, 14% fatty alcohol polyoxyethylene ether %, borax 2%, simethicone 10%, sodium benzoate 2%; the balance is supplemented by water. The components need to be dissolved in water respectively before mixing. After mixing, further dilute. The dilution ratio is 1 liter of the above cutting fluid plus 19 liters of water. After adding water, stir evenly for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com