A kind of rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and hyperbranched polyurethane, which is applied in the field of polyurethane foam preparation, can solve the problems of non-uniform rigid foam, difficult to mix uniformly, and emission of volatile organic compounds, and achieves good temperature resistance, simple process and stable size good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, 6.7 parts by weight of trimethylolpropane and 33.3 parts by weight of isophorone diisocyanate are added to a three-necked flask, and then 0.05 parts by weight of organic bismuth catalyst (BiCAT 8108, leading in the United States) is added. , reacted in N-dimethylformamide for 1 hour; then added 60 parts by weight of trimethylolpropane to continue the reaction for 3 hours to obtain a hyperbranched polyurethane polyol with a solid content of 71% and a viscosity of 1100 mPa·s.

[0031] At 30°C, add 100 parts by weight of hyperbranched polyurethane polyol, 8.5 parts by weight of water, and 4 parts by weight of organosiloxane (B8433, Degussa) into a self-made mold and stir for 30 seconds. After mixing evenly, quickly add 180 parts by weight Polymethylene polyphenyl polyisocyanate (PM-200, Yantai Wanhua), after stirring for 3 minutes, was placed in an oven at 60° C. for curing for 24 hours to prepare the rigid polyurethane foam.

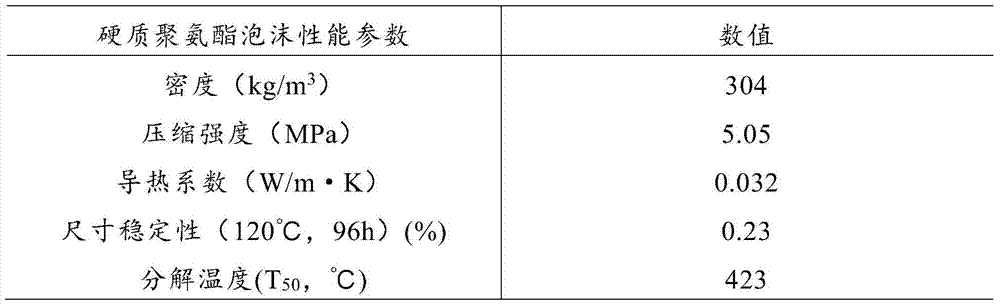

[0032] The performance test of rigid p...

Embodiment 2

[0036] First, 6.7 parts by weight of trimethylolpropane and 40 parts by weight of isophorone diisocyanate were added to a three-necked flask, then 0.10 parts by weight of dibutyltin dilaurate was added, and 40 parts by weight of N,N-dimethyl and then added 40 parts of trimethylolpropane to continue the reaction for 4 hours to obtain a hyperbranched polyurethane polyol with a solid content of 68% and a viscosity of 960 mPa·s.

[0037] At 30°C, add 100 parts by weight of hyperbranched polyurethane polyol, 8.5 parts by weight of water, and 2.8 parts by weight of organosiloxane (AK8805, Demei Shichuang) into a self-made mold and stir for 30 seconds. After mixing evenly, quickly add 140 parts by weight Polymethylene polyphenyl polyisocyanate (PM-200, Yantai Wanhua), after stirring for 3 minutes, was placed in an oven at 40° C. for curing for 48 hours to prepare the rigid polyurethane foam.

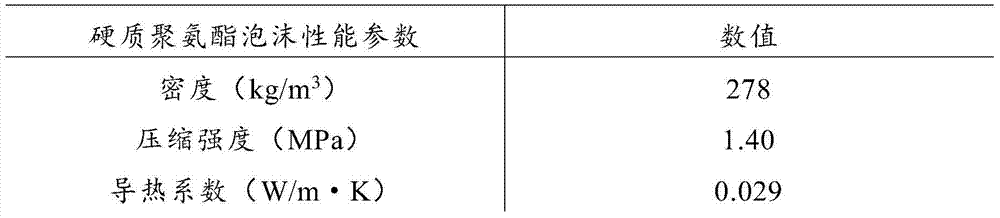

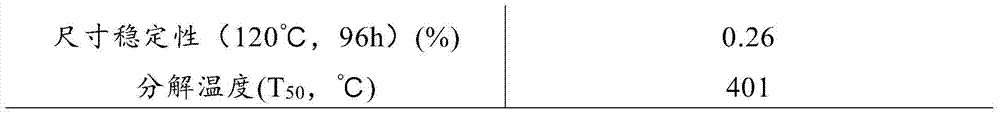

[0038] The performance test of rigid polyurethane foam was carried out, and the results are...

Embodiment 3

[0043] First, 6.7 parts by weight of trimethylolpropane and 50 parts by weight of isophorone diisocyanate are added to a three-necked flask, and then 0.15 parts by weight of organic bismuth catalyst (BiCAT 8118, leading in the United States) is added. , reacted in N-dimethylformamide for 2 hours; then added 45 parts by weight of trimethylolpropane to continue the reaction for 4 hours to obtain a hyperbranched polyurethane polyol with a solid content of 70% and a viscosity of 1050 mPa·s.

[0044] At 30°C, add 100 parts by weight of hyperbranched polyurethane polyol, 8.5 parts by weight of water, and 4 parts by weight of organosiloxane (B8450, Degussa) into a self-made mold and stir for 30 seconds. After mixing evenly, quickly add 240 parts by weight Polymethylene polyphenyl polyisocyanate (5005, Huntsman) was stirred for 3 minutes, and then put into an oven at 80° C. for 12 hours to cure to prepare the rigid polyurethane foam.

[0045] The performance test of rigid polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com