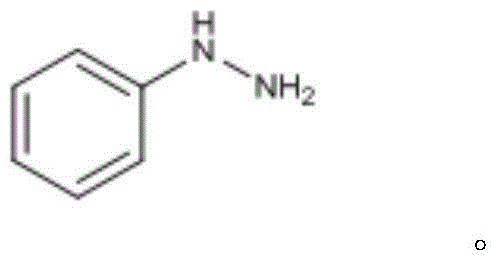

Synthetic method of phenylhydrazine

A synthetic method, the technology of phenylhydrazine, which is applied in the field of synthesis of aromatic hydrazine compounds, can solve the problems of ineffective reaction and reduced yield, and achieve the effects of high recycling value, reduced water consumption, and less waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of preparation method of phenylhydrazine, take aniline, dilute sulfuric acid, ammonium nitrite, ammonium sulfite, ammonium bisulfite, ammonia as raw material, carry out following steps successively:

[0032] 1). Measure 50ml of 50wt% sulfuric acid (0.36mol), add it into a 500ml three-necked flask, weigh 18.63g of aniline (0.20mol) and add it, a large amount of solids are precipitated, and then cool down to 0°C in an ice-salt bath. Add 90ml (2.20mol / L) ammonium nitrite solution dropwise, the dropping time is 30min, the temperature is controlled at 0-5°C during the dropwise addition, keep the temperature for 5min after the dropwise addition, and then cool down to -10°C in the ice-salt bath .

[0033] 2). Weigh 30g (0.26mol) of ammonium sulfite and 18g (0.18mol) of ammonium bisulfite into the three-necked flask directly, stir vigorously (rotating speed is 800-1200rmp), when the temperature of the reaction system naturally rises slowly to 40°C Finally,...

Embodiment 2

[0036] Embodiment 2, a kind of preparation method of phenylhydrazine, take aniline, dilute sulfuric acid, ammonium nitrite, ammonium sulfite, ammonium bisulfite, ammonia as raw material, carry out following steps successively:

[0037] 1). Take 42ml of 60wt% sulfuric acid (0.39mol), add it into a 500ml three-necked flask, weigh 18.63g of aniline (0.20mol) into it, and precipitate a large amount of solids, then cool down to 0°C in an ice-salt bath. Add 90ml (2.20mol / L) ammonium nitrite solution dropwise, the dropping time is 30min, the temperature is controlled at 0-5°C during the dropwise addition, keep the temperature for 5min after the dropwise addition, and then cool down to -10°C in the ice-salt bath .

[0038] 2). Weigh 30g of ammonium sulfite (0.26mol) and 18g of ammonium bisulfite (0.18mol) into the three-necked flask directly, stir vigorously (rotating speed is 800-1200rmp), when the temperature of the reaction system naturally rises slowly to 40°C Finally, 60wt% sulf...

Embodiment 3

[0041] Embodiment 3, a kind of preparation method of phenylhydrazine, take aniline, dilute sulfuric acid, ammonium nitrite, ammonium sulfite, ammonia as raw material, carry out following steps successively:

[0042]1). Measure 60ml of 50wt% sulfuric acid (0.43mol), add it into a 500ml three-neck flask, weigh 18.63g of aniline (0.20mol) and add it, a large amount of solids are precipitated, and then cool down to 0°C in an ice-salt bath. Add 90ml (2.20mol / L) ammonium nitrite solution dropwise, the dropping time is 30min, the temperature is controlled at 0-5°C during the dropwise addition, keep the temperature for 5min after the dropwise addition, and then cool down to -10°C in the ice-salt bath .

[0043] 2). Weigh 45g of ammonium sulfite (0.39mol) and add it directly into a three-necked flask, stir vigorously (rotating speed: 800-1200rmp), when the temperature of the reaction system naturally rises slowly to 40°C, add 50wt% sulfuric acid (about 50ml) The pH was adjusted to 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com