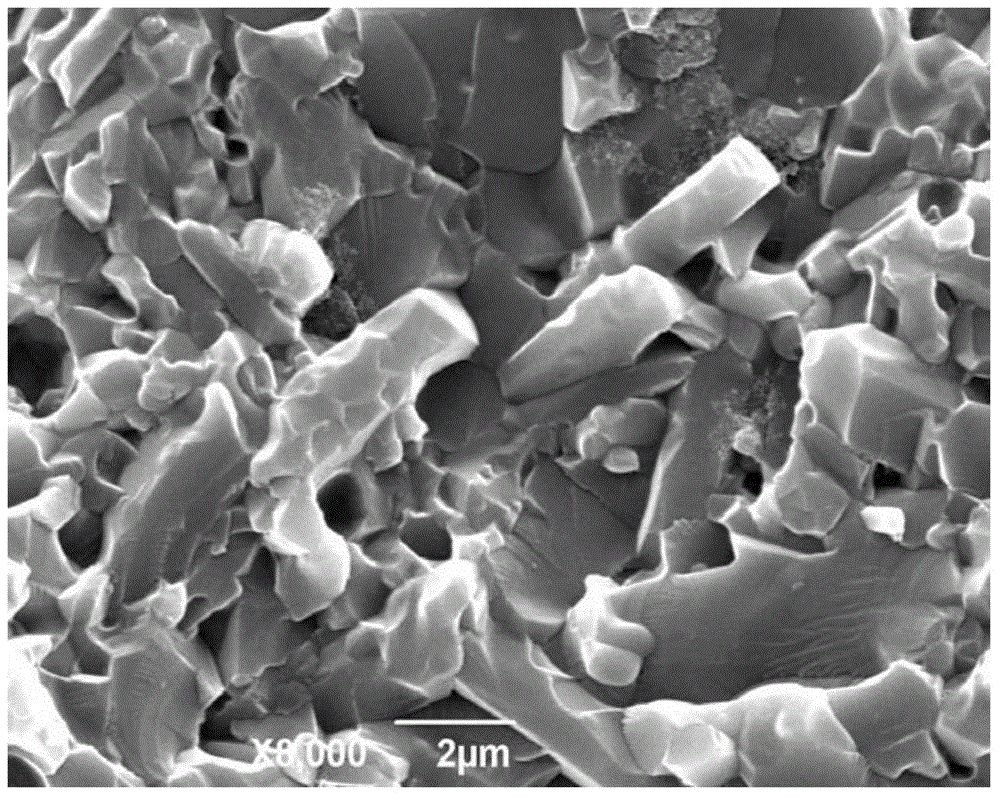

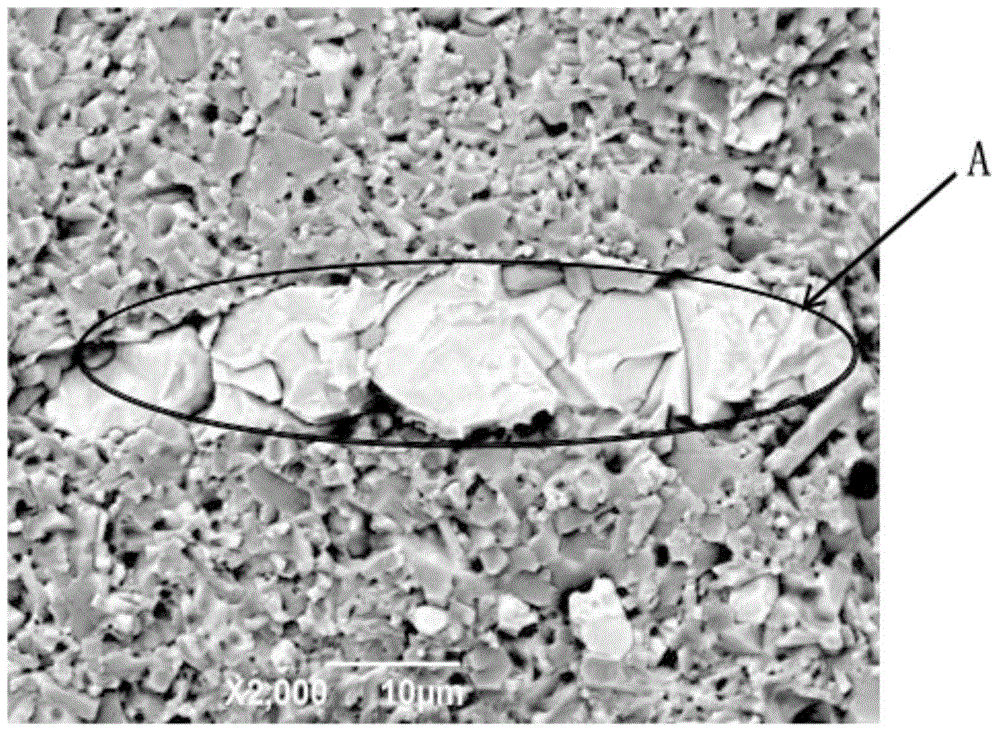

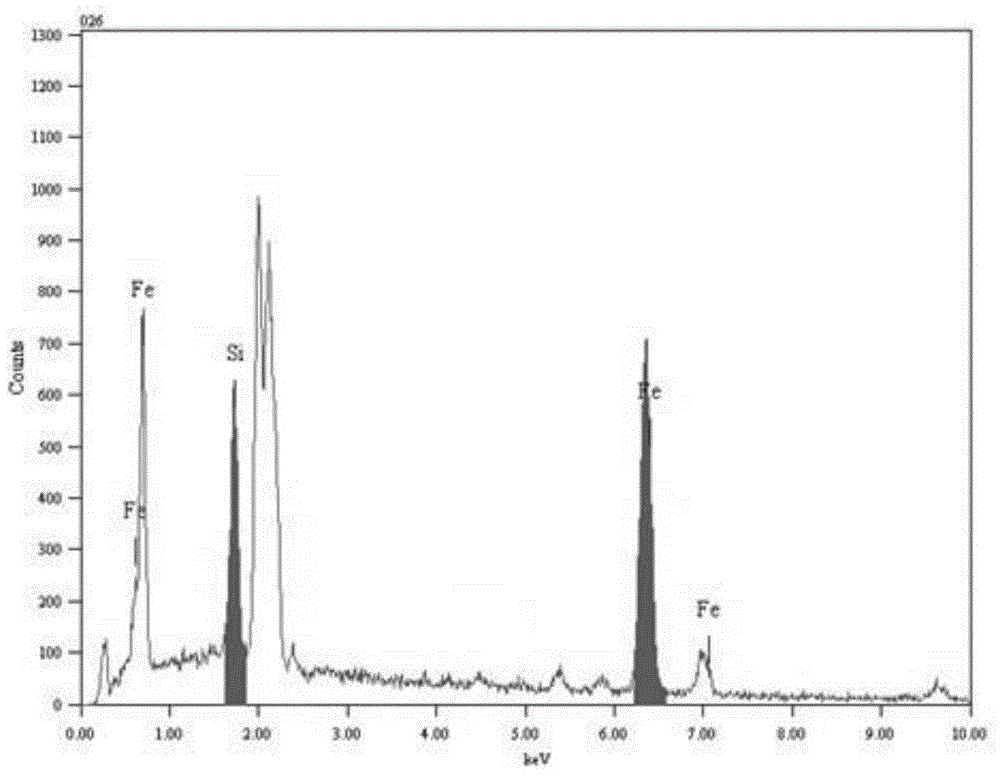

Method for preparing bulk ceramic material from iron-silicon nitride powder

A technology of ferrosilicon nitride and ceramic materials, which is applied in the field of refractory materials to achieve the effects of uniform density, high density and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] Step 1. Adopt wet ball milling method to place the following raw materials by mass percentage in a ball mill and mix them uniformly: 90% of ferrosilicon nitride powder, 3.5% of lanthanum oxide powder, 3% of yttrium oxide powder, and 3.5% of aluminum oxide powder After ball milling, the uniformly mixed material is dried to obtain mixed powder; the ball milling medium of the wet ball mill is absolute ethanol, the ball-to-material ratio of the wet ball mill is 2.5:1, and the rotating speed of the ball mill is 125r / min, The quality of the absolute ethanol is 3 times of the sum of the mass of ferrosilicon nitride powder, lanthanum oxide powder, yttrium oxide powder and aluminum oxide powder; the average particle size of the ferrosilicon nitride powder is 0.5 μm, and the average The particle size is 2 μm, the average particle size of yttrium oxide powder is 3 μm, and the average particle size of alumina powder is 0.6 μm; ...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] Step 1. Using wet ball milling method, put the following raw materials by mass percentage in a ball mill and mix them uniformly: 95% of ferrosilicon nitride powder, 2% of lanthanum oxide powder, 1% of yttrium oxide powder, and 2% of aluminum oxide powder After ball milling, the uniformly mixed material is dried to obtain mixed powder; the ball milling medium of the wet ball mill is absolute ethanol, the ball-to-material ratio of the wet ball mill is 2:1, and the rotating speed of the ball mill is 150r / min, The quality of the absolute ethanol is 2 times of the sum of the mass of ferrosilicon nitride powder, lanthanum oxide powder, yttrium oxide powder and alumina powder; the average particle size of the ferrosilicon nitride powder is 0.4 μm, and the average The particle size is 3 μm, the average particle size of yttrium oxide powder is 2 μm, and the average particle size of alumina powder is 0.7 μm;

[0033] Step 2,...

Embodiment 3

[0037] This embodiment includes the following steps:

[0038] Step 1. Adopt wet ball milling method to place the following raw materials by mass percentage in a ball mill and mix them uniformly: 85% of ferrosilicon nitride powder, 5% of lanthanum oxide powder, 5% of yttrium oxide powder, and 5% of aluminum oxide powder After ball milling, the uniformly mixed material is dried to obtain a mixed powder; the ball milling medium of the wet ball mill is absolute ethanol, the ball-to-material ratio of the wet ball mill is 3:1, and the rotating speed of the ball mill is 100r / min, The quality of the absolute ethanol is the sum of the mass of ferrosilicon nitride powder, lanthanum oxide powder, yttrium oxide powder and alumina powder; the average particle size of the ferrosilicon nitride powder is 0.7 μm, and the average particle size of the lanthanum oxide powder is 1 μm , the average particle size of yttrium oxide powder is 2 μm, and the average particle size of alumina powder is 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com