Method for treating disperse blue 56 reducing mother-liquor wastewater

A treatment method and technology for dispersing blue, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as waste of resources and failure to realize the recovery of inorganic sodium salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

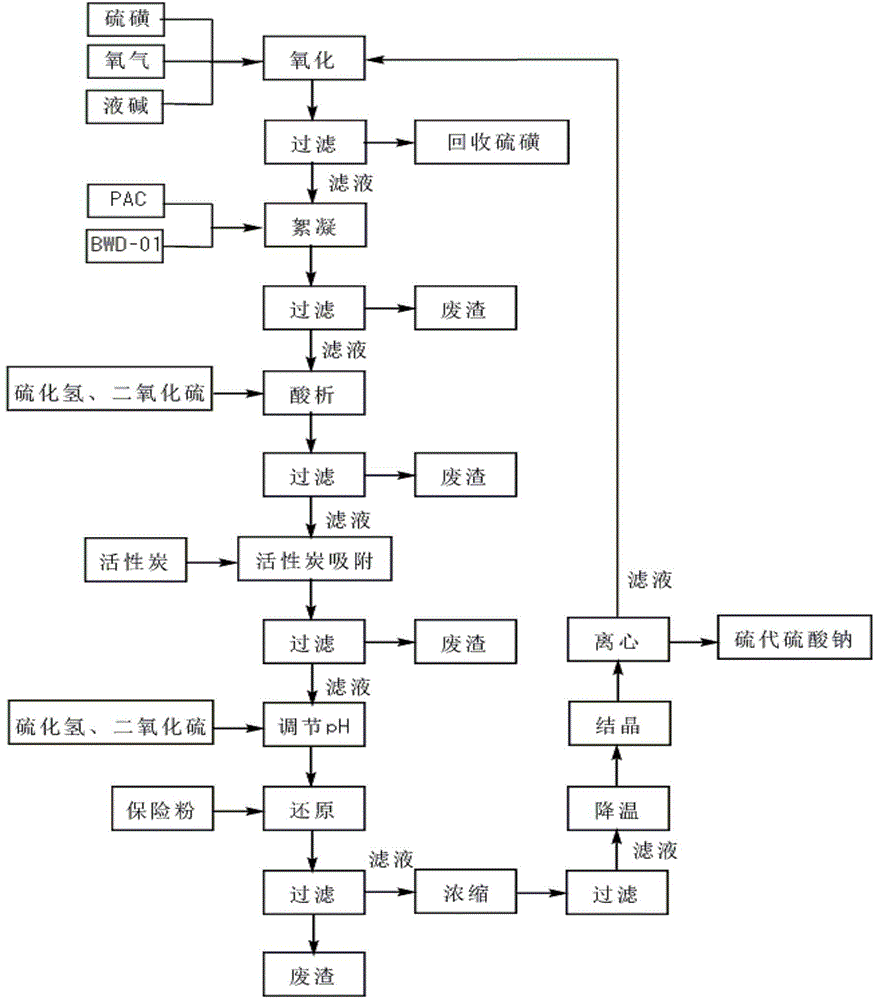

Method used

Image

Examples

Embodiment 1

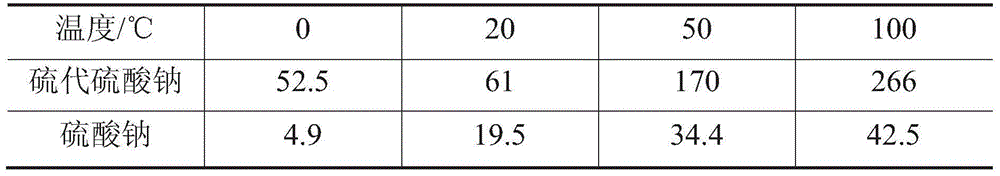

[0077] Disperse Blue 56 reduced mother liquor wastewater was initially filtered, and the measured pH was 13.6, COD was about 28440mg / L, containing 2.2% sodium sulfide (based on wastewater quality), and 0.4% sodium hydroxide (based on wastewater quality), Wastewater is dark blue suspension.

[0078] (1) Reduction: Add 9g of sulfur to 400mL of waste water, heat to 100°C, keep stirring for 1.5h.

[0079] In the reduction reaction, the hydroxide ions in the system participate in the reaction, and the pH value of the system decreases continuously during the reaction process, and it is necessary to ensure that the pH value is not lower than 8.

[0080] (2) Oxidation: Oxygen is introduced into the waste water after reduction, the temperature is lowered to 50° C. after the heat preservation reaction is continued for 4 hours, filtrate I is obtained by filtration, and sulfur is recovered.

[0081] The pH and temperature were monitored online throughout the reaction, and the pH was adju...

Embodiment 2

[0104] Disperse blue 56 reduced mother liquor wastewater was pre-filtered, pH > 14, COD about 38575mg / L, sodium sulfide 3.2%, sodium hydroxide 0.49%, overall dark blue suspension.

[0105] (1) Reduction: Add 9g of sulfur to 400mL of wastewater, and keep it warm at 80°C for 2.5 hours under stirring conditions. The hydroxide ions in the system will participate in the reaction during the reduction reaction. Its pH value is not lower than 8.

[0106] (2) Oxidation: Feed oxygen into the waste water after reduction, continue to insulate for 4 hours, cool down and filter, obtain filtrate I, reclaim sulfur. After the reaction, the waste water had no obvious color change.

[0107] During the whole reaction, the pH of the reaction system was controlled to be 8 with an aqueous solution of sodium carbonate with a mass fraction of 30%.

[0108] (3) Flocculation: Add a mixed flocculant to the filtrate I {preparation method: add PAC (polyaluminum chloride) 0.03 g, BWD-01 (dicyandiamide for...

Embodiment 3

[0122] Disperse blue 56 reduction mother liquor wastewater was pre-filtered, and the measured pH was 13.6, COD was about 28440mg / L, containing 2.2% sodium sulfide and 0.4% sodium hydroxide, and the wastewater was dark blue suspension.

[0123] (1) Reduction: Add 11g of sulfur to 400mL of waste water, and keep it warm at 100°C for 1.5 hours under stirring conditions. During the reduction reaction, the hydroxide ions in the system will participate in the reaction. Its pH value is not lower than 8.

[0124] (2) Oxidation: Feed oxygen into the waste water after the reduction, continue the heat preservation reaction for 3 hours and then cool down and filter to obtain filtrate I and reclaim sulfur. After the reaction, the waste water had no obvious color change.

[0125] During the whole reaction process, the pH of the reaction system was controlled to be 9 with a mixed aqueous solution of sodium hydroxide and sodium carbonate with a mass fraction of 30%.

[0126] (3) Flocculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com