A kind of composite graphite negative electrode material and preparation method thereof

A technology of composite graphite and negative electrode materials, which is applied in chemical instruments and methods, carbon compounds, battery electrodes, etc., can solve the problems of poor graphite rate performance, high current charge and discharge performance, and poor compaction performance, so as to improve compatibility performance, high-current charging and discharging performance, and high-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

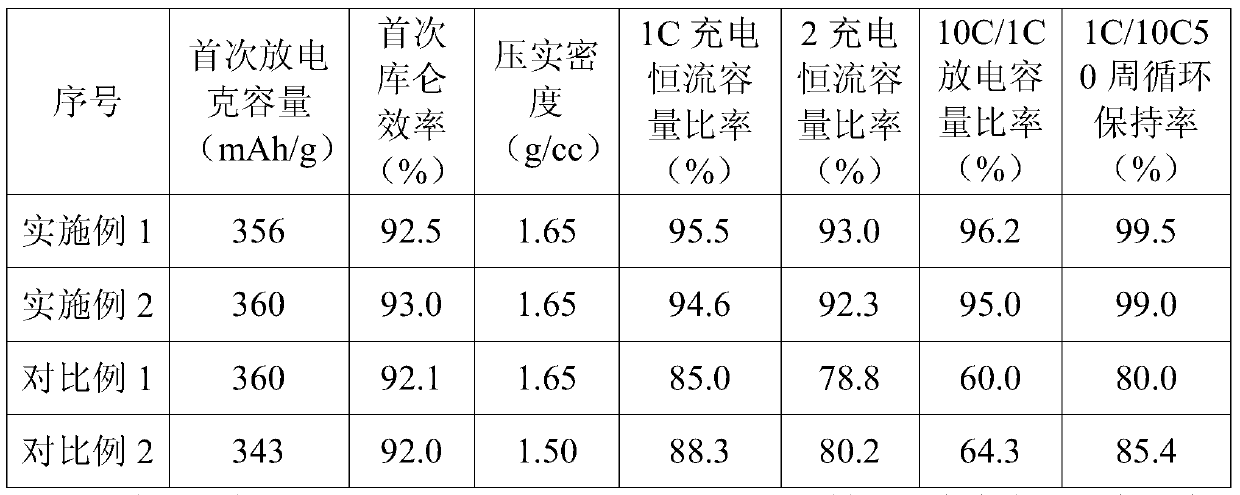

Embodiment 1

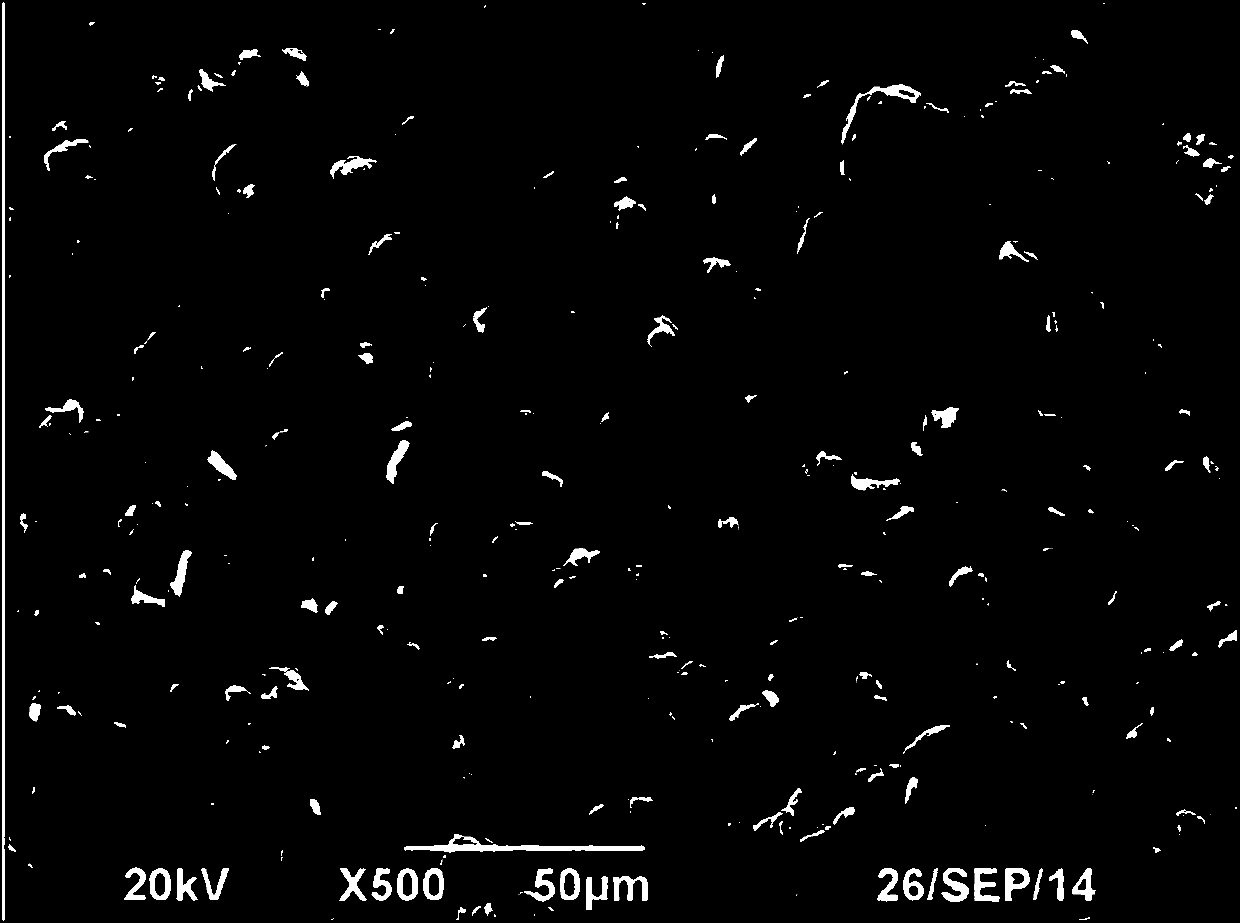

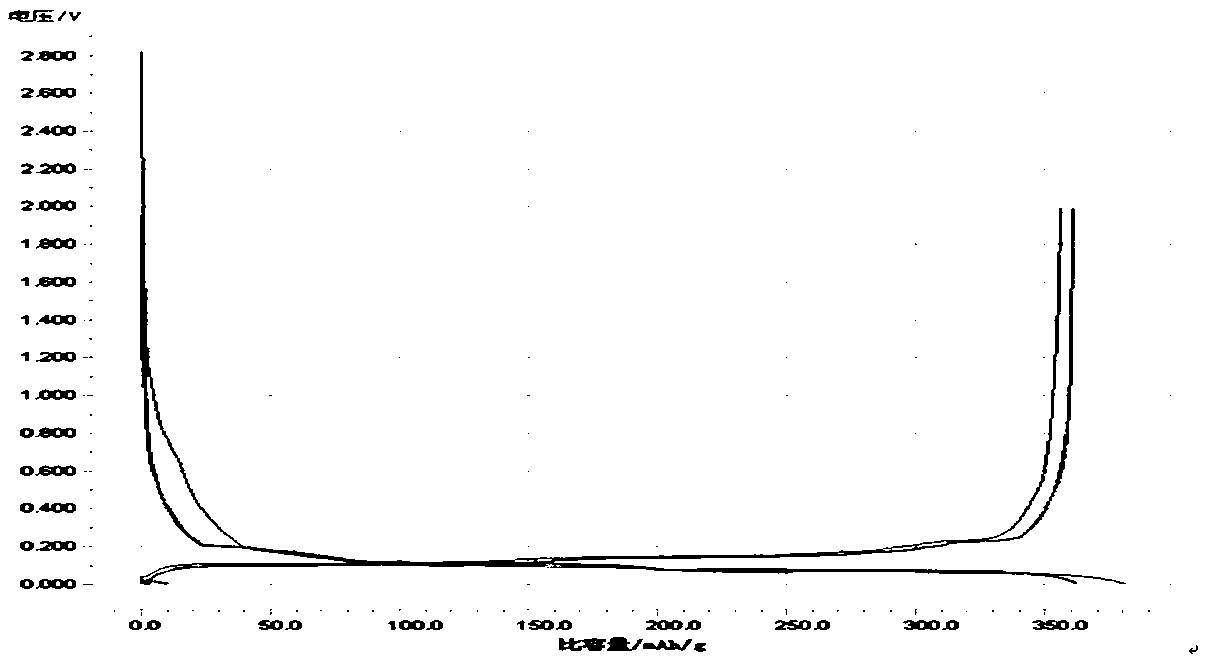

[0050] Oil-based petroleum coke is crushed into 3um particles by jaw crusher and machine, and 230kg of the ground petroleum coke particles, 30kg of coal tar pitch (D50 10um) and 2.6kg of graphitization catalyst SiC are thrown into the reactor, and the materials are added while stirring , heating after feeding. Adjust the rotating speed of the drum to 30Hz, and the heating program is as follows: room temperature to 200°C for 1.5 hours, 200°C to 400°C for 2.5 hours, 400°C to 600°C for 2.5 hours, 600°C for 2.5 hours. Let cool to room temperature. Then it is catalyzed and graphitized at 2900°C under chlorine gas. Artificial graphite secondary particles (D50 9.0um) were prepared.

[0051] Throw 222.5kg of natural graphite particles (D50 5um), 25kg of coal tar pitch (D50 10um) and 2.5kg of graphitization catalyst SiC into the drum furnace, feed while the drum is rotating, and heat and knead after feeding. Adjust the rotating speed of the drum to 30Hz, and the heating program is a...

Embodiment 2

[0054] The coal-based petroleum coke is crushed into 4um particles by jaw crusher and machine, and 220kg of the ground petroleum coke particles, 20kg of coal tar pitch (D50 10um) and 2.4kg of graphitization catalyst SiC are thrown into the reactor, and the materials are added while stirring. , heating after feeding. Adjust the rotating speed of the drum to 30Hz, and the heating program is as follows: room temperature to 200°C for 1 hour, 200°C to 400°C for 2 hours, 400°C to 600°C for 2.5 hours, 600°C for 3.5 hours. Let cool to room temperature. Then it is catalyzed and graphitized at 2900°C under chlorine gas. Artificial graphite secondary particles (D50 10.0um) were prepared.

[0055] Throw 225kg of natural graphite particles (D50 4um), 26kg of coal tar pitch (D50 10um) and 2.8kg of graphitization catalyst SiC into the drum furnace, feed while the drum is rotating, and heat and knead after feeding. Adjust the rotating speed of the drum to 30Hz, and the heating program is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com