Method of regulating and controlling lengths of silver nanorods in polyhydric alcohol reduction method through hydrogen peroxide

A silver nanorod, hydrogen peroxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the length cannot be easily adjusted, and achieve uniqueness, low cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

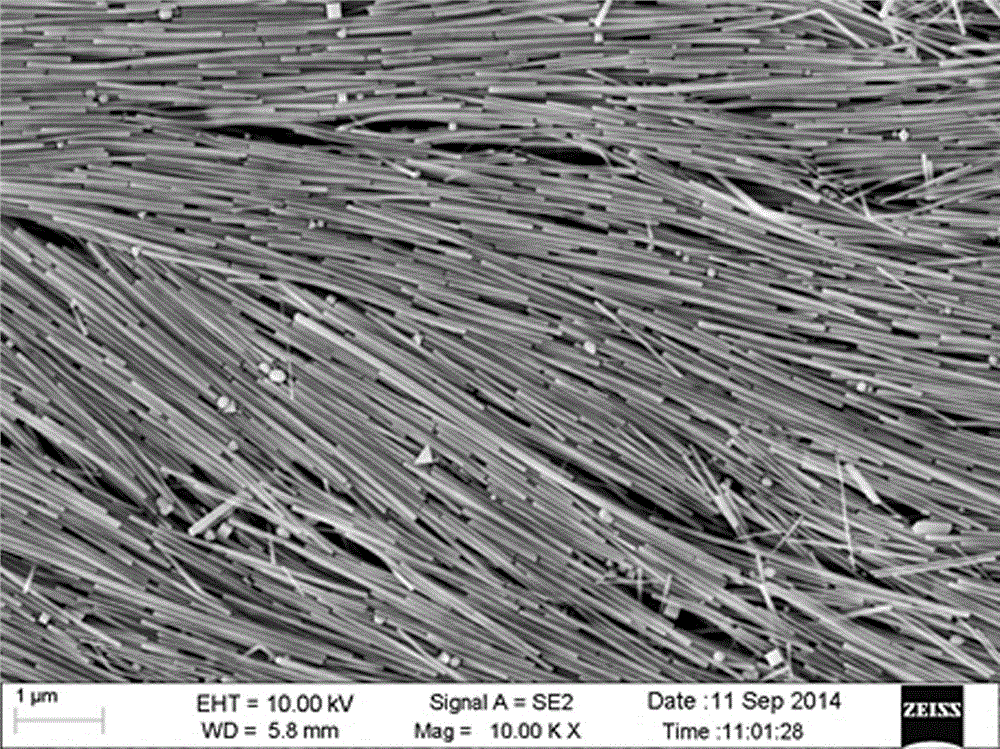

Embodiment 1

[0029] (1) Mix 1.0g silver nitrate and 1mL (1.3g) glycerol at room temperature, stir and dissolve to obtain solution A;

[0030] (2) Add 10mg of sodium chloride, 10g of polyvinylpyrrolidone, 59mL (77g) of glycerol and 10μL (0.00001g) of hydrogen peroxide into a three-necked round-bottomed flask in sequence, cover the three-necked round-bottomed flask with a stopper, and suspend in In an oil bath at 180°C, stir and react for 1 hour to obtain solution B;

[0031] (3) Add solution A to solution B, the mass ratio of solution A to solution B is 1:39.6, then stir and react at 180°C for 15 minutes, centrifuge the reaction solution, remove the lower precipitate, wash with water, and obtain a length of 2.10± 0.28 µm silver nanorods.

Embodiment 2

[0033] (1) Mix 1.0g silver nitrate and 1mL (1.3g) glycerol at room temperature, stir and dissolve to obtain solution A;

[0034] (2) Add 10mg of sodium chloride, 10g of polyvinylpyrrolidone, 59mL (77g) of glycerol and 100μL (0.0001g) of hydrogen peroxide into the three-necked round-bottomed flask in turn, cover the three-necked round-bottomed flask with a stopper, and suspend in In an oil bath at 180°C, stir and react for 1 hour to obtain solution B;

[0035] (3) Add solution A to solution B, the mass ratio of solution A to solution B is 1:39.6, then stir and react at 180°C for 15 minutes, centrifuge the reaction solution, remove the lower precipitate, wash with water, and obtain a length of 1.35± 0.22 µm silver nanorods.

Embodiment 3

[0037] (1) Mix 1.0g silver nitrate and 1mL (1.3g) glycerol at room temperature, stir and dissolve to obtain solution A;

[0038] (2) Add 10mg of sodium chloride, 10g of polyvinylpyrrolidone, 59mL (77g) of glycerol and 400μL (0.0004g) of hydrogen peroxide into the three-necked round-bottomed flask in sequence, cover the three-necked round-bottomed flask with a stopper, and suspend in In an oil bath at 180°C, stir and react for 1 hour to obtain solution B;

[0039] (3) Add solution A to solution B, the mass ratio of solution A to solution B is 1:39.6, then stir and react at 180°C for 15 minutes, centrifuge the reaction solution, remove the lower precipitate, wash with water, and obtain a length of 1.12± 0.23 micron silver nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com