Tilmicosin enteric micro pellet

A technology of tilmicosin and enteric-coated pellets, which is applied to medical preparations of non-active ingredients, organic active ingredients, antibacterial drugs, etc., can solve problems such as bitter taste and limited masking effect, and achieve improved stability, Avoid waste and improve the effect of drug utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

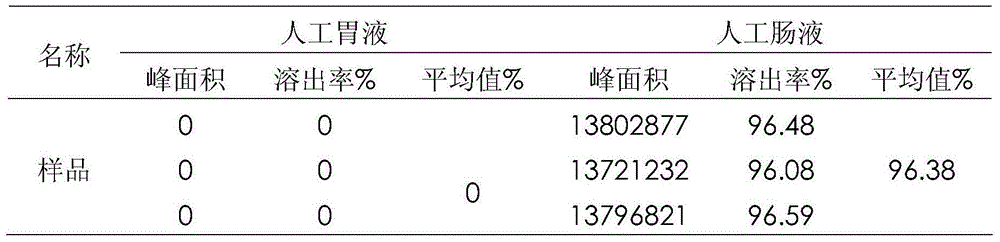

Examples

Embodiment 1

[0019] Composition of tilmicosin pellet core:

[0020] Tilmicosin 30%

[0021] Microcrystalline Cellulose 40%

[0022] Sodium Carboxymethyl Starch 30%

[0023] Mix the claimed raw materials with appropriate amount of purified water, the solid-liquid ratio is 3:1, put them into a tank mixer and mix for 30 minutes to obtain the pellet core. Composition of coating liquid for tilmicosin pellets:

[0024] Acrylic 50%

[0025] Triethyl Citrate 10%

[0026] Talc 40%

[0027] Add an appropriate amount of water to prepare a coating solution, and the mass ratio of the ball core to the coating material is 2:1;

[0028] Add an appropriate amount of hydroxypropyl methylcellulose into purified water and shear for 15 minutes to prepare a binder with a concentration of 2.5%; put the binder and the ball core into the groove machine and mix evenly, the weight of the binder and the ball core The ratio is 1:2.

[0029] Put the pellet core and binder into the extruder and spheronizer for e...

Embodiment 2

[0031] Composition of tilmicosin pellet core:

[0032] Tilmicosin 55%

[0033] Microcrystalline Cellulose 35%

[0034] Sodium Carboxymethyl Starch 10%

[0035] Mix the claimed raw materials with appropriate amount of purified water, the solid-liquid ratio is 3:1, put them into a tank mixer and mix for 30 minutes to obtain the pellet core. Composition of coating liquid for tilmicosin pellets:

[0036] Acrylic 60%

[0037] Triethyl Citrate 8%

[0038] Talc 32%

[0039] Add an appropriate amount of water to prepare a coating solution, and the mass ratio of the ball core to the coating material is 2:1;

[0040] Add an appropriate amount of povidone into purified water and shear for 15 minutes to prepare a binder with a concentration of 2.5%; put the binder and the ball core into the groove machine and mix evenly, and the weight ratio of the binder to the ball core is 1: 2. Put it into the extruder and spheronizer for extrusion, spheronization, and drying; use 30 mesh and 60...

Embodiment 3

[0042] Composition of tilmicosin pellet core:

[0043] Tilmicosin 60%

[0044] Microcrystalline Cellulose 20%

[0045] Sodium Carboxymethyl Starch 20%

[0046] Mix the claimed raw materials with appropriate amount of purified water, the solid-liquid ratio is 3:1, put them into a tank mixer and mix for 30 minutes to obtain the pellet core. Composition of coating liquid for tilmicosin pellets:

[0047] Acrylic 70%

[0048] Triethyl Citrate 5%

[0049] Talc 25%

[0050] Add an appropriate amount of water to prepare a coating solution, and the mass ratio of the ball core to the coating material is 2:1;

[0051] Add an appropriate amount of starch into purified water and cut for 15 minutes to prepare a binder with a concentration of 2.5%; put the binder into the groove machine and mix it with the ball core. The weight ratio of the binder to the ball core is 1:2. put into the extruder and spheronizer for extrusion, spheronization, and dry; use 30 mesh and 60 mesh sieves for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com