Indoxacarb contained virus insecticide suspension agent

A virus insecticidal and suspending agent technology, applied in insecticides, biocides, animal repellents, etc., can solve serious problems such as poor control effect of indoxacarb, delay resistance, expand insecticidal spectrum, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

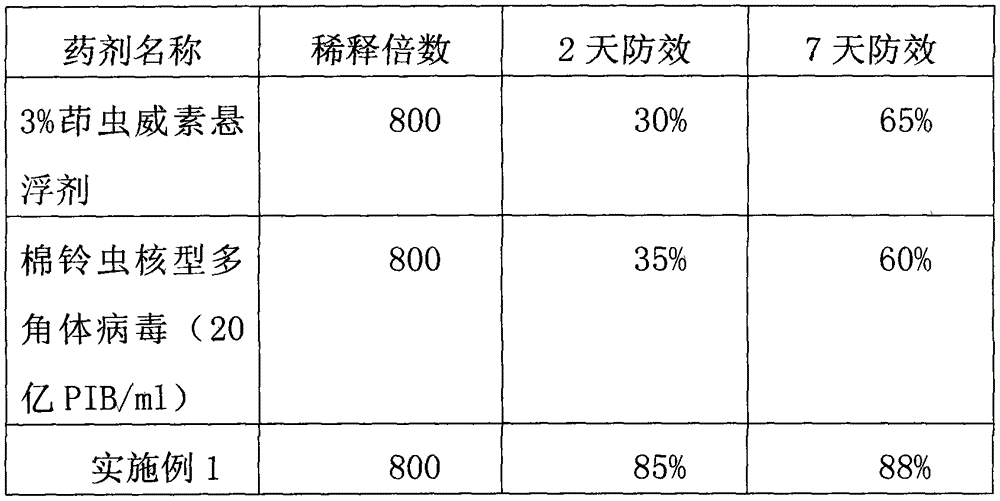

Embodiment 1

[0026] The selected materials are composed as follows in percentage by weight: 3 kilograms of indoxacarb; 10 kilograms of parent drug of cotton bollworm nuclear polyhedrosis virus (20 billion PIB / ml); 10 kilograms of sodium lignosulfonate; 7 kilograms of ethylene glycol; 10 kg of glue; 0.3 kg of fluorescent whitening agent; 2 kg of phenylalanine; 0.2 kg of silicone defoamer; 0.1 kg of hydrochloric acid (for pH adjustment); add water to 100 kg.

[0027] Put the above-mentioned raw materials in the ball mill, start the ball mill to pulverize; when the particle diameter reaches 74 microns (200 mesh), put the material into the sand mill, feed cooling water, and carry out the sand mill ultrafine pulverization, the sand mill end point is 3 microns; put the mixture into a homogenizer and pour it into a sealed container.

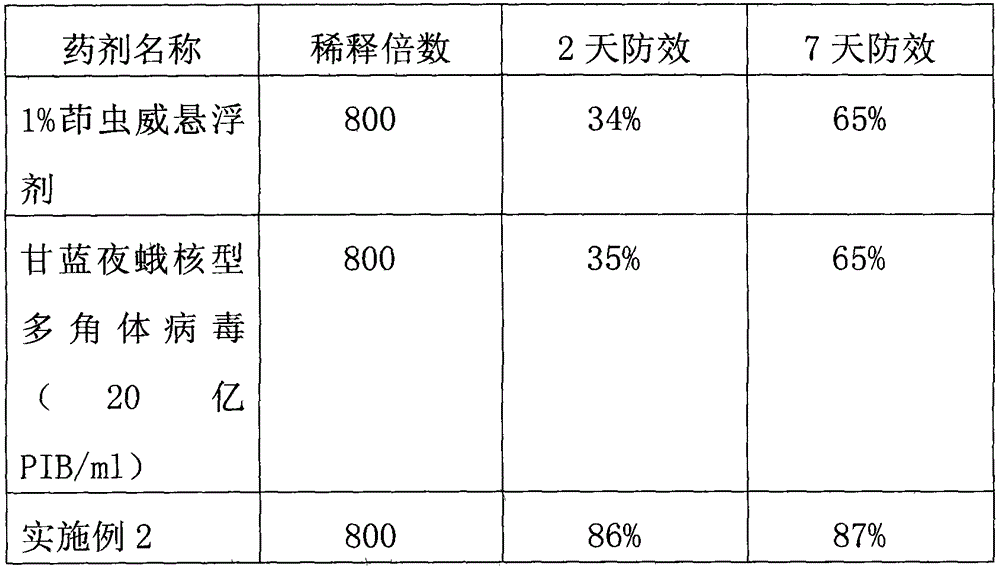

Embodiment 2

[0029] The selected material is composed as follows in weight percentage: 1 kilogram of indoxacarb; 10 kilograms of parent drug of cabbage armyworm nuclear polyhedrosis virus (20 billion PIB / ml); 10 kilograms of sodium lignosulfonate; 7 kilograms of ethylene glycol; 10 kg of methyl cellulose; 0.3 kg of fluorescent whitening agent; 3 kg of tyrosine; 0.2 kg of silicone defoamer; 0.1 kg of acetic acid (for pH adjustment); add water to 100 kg.

[0030] Put the above-mentioned raw materials in the ball mill, start the ball mill to pulverize; when the particle diameter reaches 74 microns (200 mesh), put the material into the sand mill, feed cooling water, and carry out the sand mill ultrafine pulverization, the sand mill end point is 3 microns; put the mixture into a homogenizer and pour it into a sealed container.

Embodiment 3

[0032] The selected material is composed as follows in weight percentage: 3 kilograms of indoxacarb; 10 kilograms of codling moth granular virus parent drug (20 billion PIB / ml); 10 kilograms of sodium lignosulfonate; 7 kilograms of propylene glycol; 10 kilograms of sodium polyacrylate 0.3 kg of fluorescent whitening agent; 3 kg of tryptophan; 0.2 kg of n-decyl alcohol defoamer; 0.1 kg of potassium hydroxide (for pH adjustment); add water to 100 kg.

[0033] Put the above-mentioned raw materials in the ball mill, start the ball mill to pulverize; when the particle diameter reaches 74 microns (200 mesh), put the material into the sand mill, feed cooling water, and carry out the sand mill ultrafine pulverization, the sand mill end point is 3 microns; put the mixture into a homogenizer and pour it into a sealed container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com