Simple gas detector for exhaust gas treatment

A gas detector and waste gas treatment technology, applied in the direction of material resistance, etc., can solve the problems of high use cost, poor detection effect, danger, etc., and achieve the effect of simple structure and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

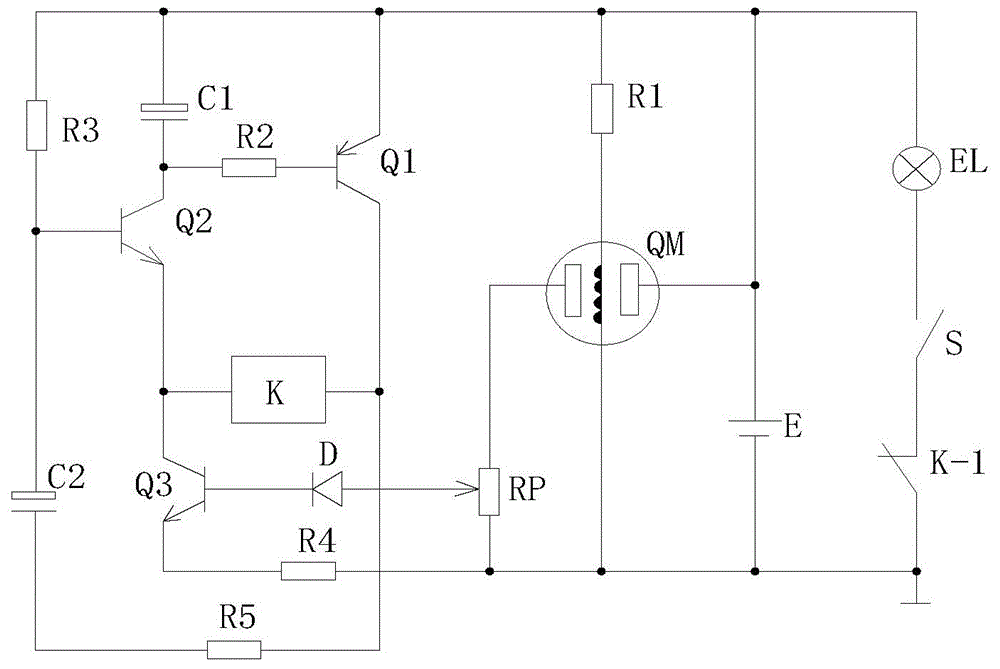

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] Such as figure 1 As shown, the present invention includes a first capacitor C1, a second capacitor C2, a first resistor R1, a second resistor R2, a third resistor R3, a fourth resistor R4, a fifth resistor R5, an indicator light EL, a first triode Q1, the second transistor Q2, the third transistor Q3, diode D, relay K, potentiometer RP, gas sensor QM, battery E and switch S, the first capacitor C1 and the second capacitor C2 are polar Capacitor, the first triode Q1 is PNP type, the second triode Q2 and the third triode Q3 are both NPN type, the first end of the third resistor R3 is connected with the positive pole of the first capacitor C1, the first three The emitter of the electrode tube Q1, the first end of the first resistor R1, the first end of the gas sensor QM, the positive electrode of the battery E and the first end of the indicator light EL are connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com