Weft accumulator sensing component and weft accumulator

A sensor component and weft feeder technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of difficult adjustment of detection pressure, failure of Hall element detection, etc., to achieve constant yarn tension and prolong service life. , the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

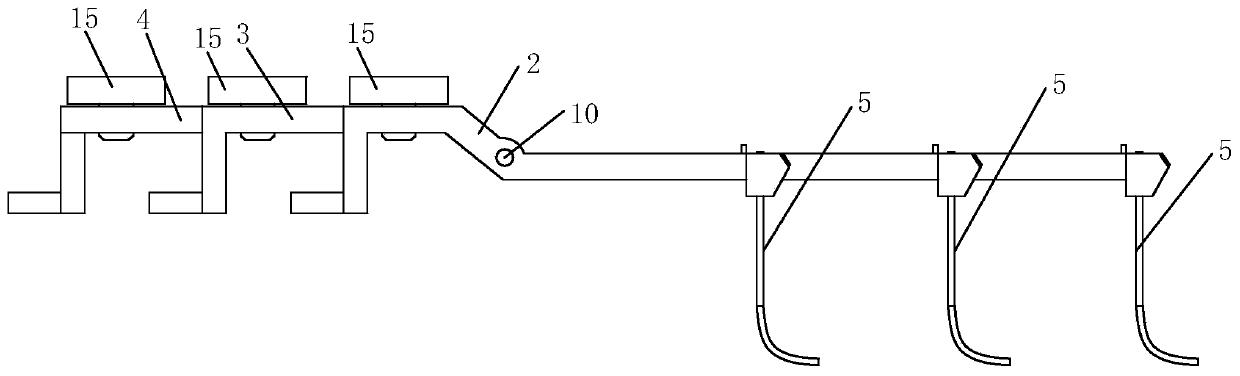

[0039] Example 1: Please refer to Figure 1-12 shown. A sensing component of a weft feeder in the present invention comprises a sensor seat 1, a short probe rod 2, a middle probe rod 3 and a long probe rod 4, a detection contact piece 5, and a motor control board 6, on which three groups of photoelectric The sensor 7 is provided with a mounting groove 11 on the upper side of the sensor seat 1, and the short probe rod 2, the middle probe rod 3 and the long probe rod 4 are placed side by side in the mounting groove 11, and the short probe rod 2, the middle probe rod 3 and the long probe rod 4 The middle part is hinged to the left side of the installation groove 11 through the revolving pin 7, and the middle part of the corresponding short probe rod 2, middle probe rod 3 and long probe rod 4 is provided with a through hole 10 for the revolving pin 7 to pass through, and the bottom of the mounting groove 11 The left side, the middle part and the right side are provided with a lef...

Embodiment 2

[0045] Example 2: Please refer to Figure 1-12 shown. A weft feeder using the sensor assembly of the weft feeder, comprising a motor protection case 20, a motor 30, a yarn winding disc 40, a yarn storage drum 50, and a shield 60, the motor 30 is arranged in the motor protection case 20, and the motor The right side of the protective case 20 is provided with a yarn winding disc 40 and a yarn storage drum 50 connected to the yarn winding disc 40. A shield 60 is connected from the upper side of the motor protection case 20 to the upper side of the yarn storage drum. It is characterized in that the sensor seat 1 is connected to Inside the shield 60, the motor control board 6 is connected to the side of the shield 60 close to the motor protection shell 20, the control end of the motor 30 is electrically connected to the motor control board 6, and the motor protection shell 20 is provided with an electrical connection with the motor control board 6. connection control button, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com